Electro-spindle performance automatic detection device

A technology of automatic detection device and electric spindle, applied in the direction of measuring device, instrument, etc., can solve the problems of low automation level, complicated detection method, incomplete detection signal, etc., and achieve the effect of improving personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

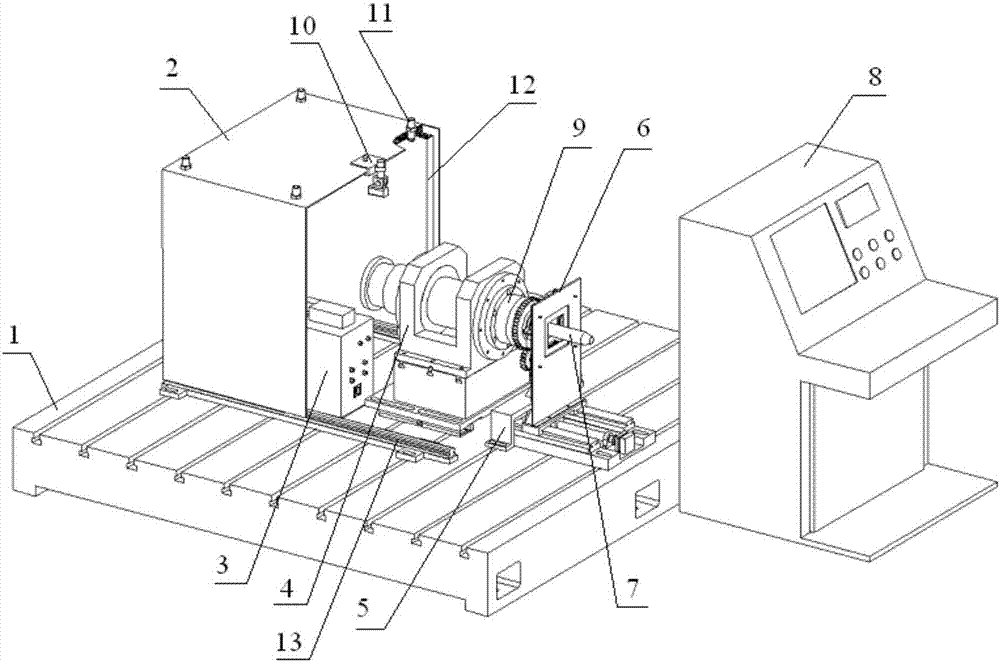

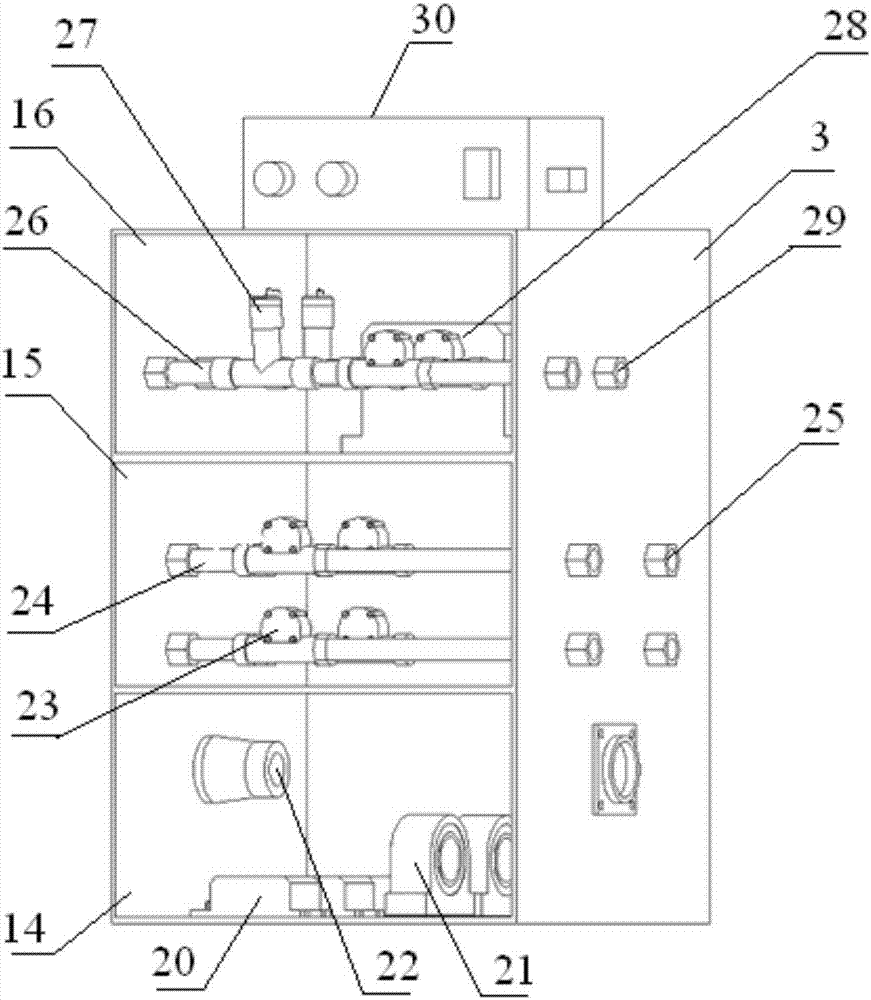

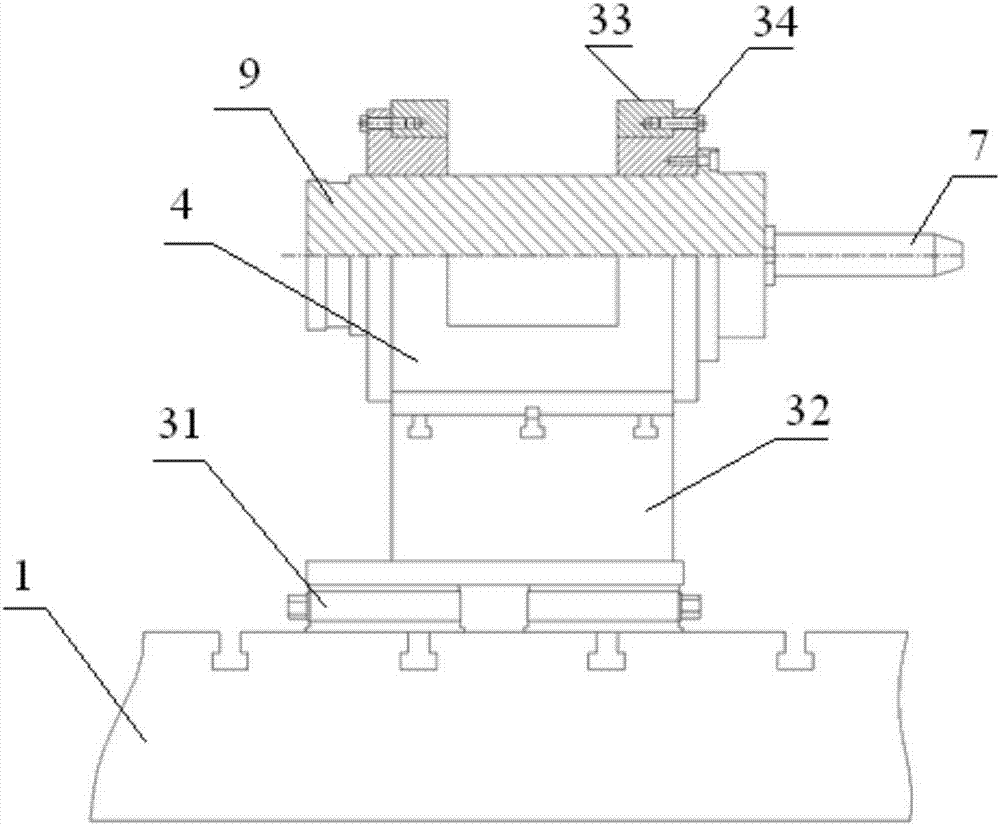

[0029] see Figure 1 to Figure 8 Shown:

[0030] The electric spindle performance automatic detection device provided by the present invention includes a ground iron 1, a protective cover 2, a noise monitoring mechanism, a comprehensive detection box 3, a spindle support mechanism 4, a vibration signal detection mechanism 5, a line laser displacement detection mechanism 6, and a detection rod 7 and the control cabinet 8, wherein the protective cover 2, the comprehensive detection box 3, the main shaft support mechanism 4, the vibration signal detection mechanism 5 and the line laser displacement detection mechanism 6 are all set on the horizontal iron 1, and the noise monitoring mechanism is assembled on the protective cover 2, The main shaft support mechanism 4 is equipped with the main shaft 9 to be tested, and the comprehensive detection box 3 is arranged at the tail of the main shaft 9 to be tested. The input quantity detection of the measuring spindle 9 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com