Portable sample analysis preprocessor and usage

A sample analysis and pre-processor technology, applied in the field of chemical experimental appliances, can solve the problems of slow sample processing, cumbersome operation, operator injury, etc., to achieve a pollution-free environment for personal health, improve concentration and evaporation speed, and protect personal health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

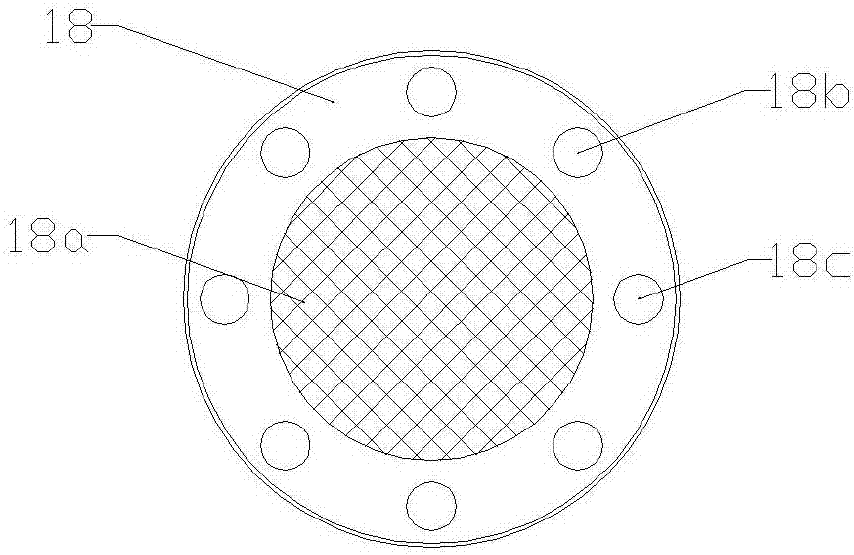

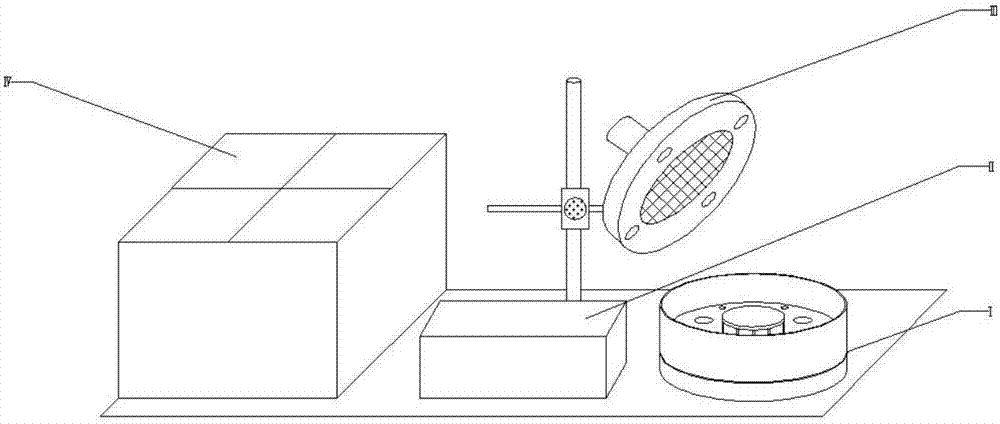

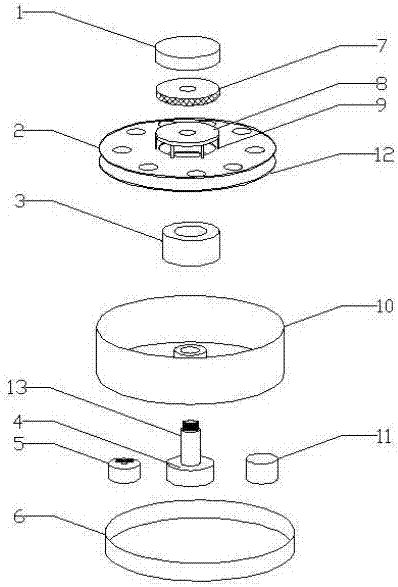

[0030] Parts of the Portable Sample Analysis Preprocessor: Parts of the Reaction Unit I, see figure 2 , with a reaction tank 10, a vessel fixed plate 2, a vessel tray 12, a fixed rod 9, a force guide 8, a rotator 4, an electromagnetic stirrer 5, an ultrasonic generator 11, a far-infrared generator 3, a fixed nut 7, and a chassis 6 and decorative cover1. See Figure 5 , Image 6 , the ventilation device III is composed of an exhaust assembly and a support assembly, the exhaust assembly has a fixed frame 17, an exhaust fan 16, a lighting fixture 15, a front cover 18, a back panel 14 and a buckle cover 24, and the support assembly has a stand base 28, a column 25, cross connector 27 and universal joint connecting rod 26. See Figure 8 , Exhaust gas treatment device IV has buffer tank 21, gas washing tank 20, absorption tank 19 and air pump 22.

[0031] Portable sample analysis preprocessor of the present invention, see figure 1 , including reaction device I, ventilation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com