Preparation method of chitosan/agarose xerogel particles and application of chitosan/agarose xerogel particles in cigarette filter tip

A technology of xerogel particles and chitosan, applied in the application, tobacco, tobacco processing and other directions, to improve the quality of smoking, increase the coordination of smoke, reduce the effect of miscellaneous gas and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

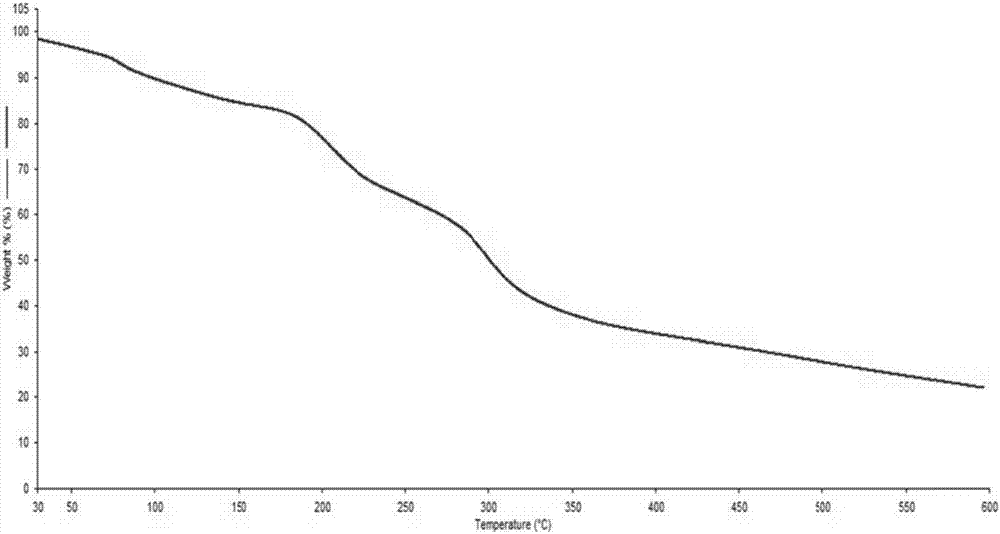

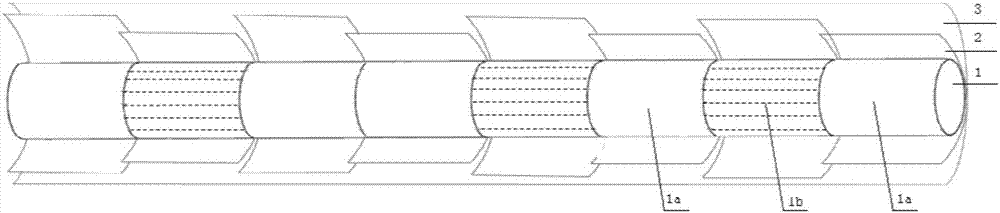

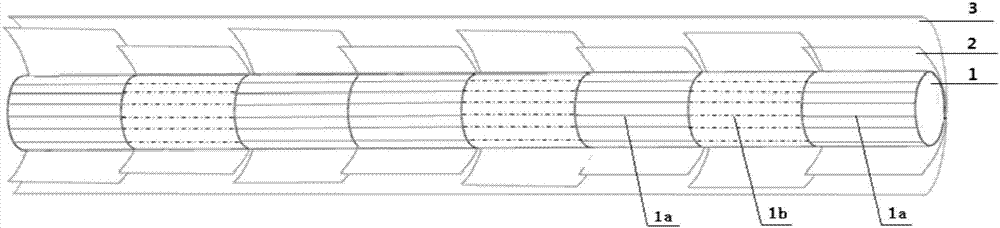

example 1

[0035] Weigh chitosan and agarose in a mass ratio of 0.2:1 and place them in 2% citric acid solution at a ratio of 40% to prepare a uniform chitosan / agarose hydrogel after heating at 100°C. The resulting hydrogel is frozen The xerogel obtained after drying is mechanically pulverized and sieved to obtain chitosan / agarose xerogel powder. Chitosan / agarose xerogel powder is prepared into granules by high-speed stirring and granulation, dried at a constant temperature of 60°C for about half an hour to obtain chitosan / agarose xerogel particles, and sieved to obtain 20-40 mesh standards Sample particle 1.

example 2

[0037] Weigh chitosan and agarose at a mass ratio of 1:1 and place them in 1.5% citric acid solution at a ratio of 30% to prepare a uniform chitosan / agarose hydrogel after heating at 100°C. The resulting hydrogel is frozen The xerogel obtained after drying is mechanically pulverized and sieved to obtain chitosan / agarose xerogel powder. Chitosan / agarose xerogel powder is prepared into granules by high-speed stirring and granulation, dried at a constant temperature of 60°C for about half an hour to obtain chitosan / agarose xerogel particles, and sieved to obtain 20-40 mesh standards Sample particle 2.

example 3

[0039]Weigh chitosan and agarose according to the mass ratio of 2:1, place them in 1% citric acid solution at a ratio of 25% and heat them at 100°C to prepare a uniform chitosan / agarose hydrogel, and the resulting hydrogel is frozen The xerogel obtained after drying is mechanically pulverized and sieved to obtain chitosan / agarose xerogel powder. Chitosan / agarose xerogel powder is prepared into granules by high-speed stirring and granulation, dried at a constant temperature of 60°C for about half an hour to obtain chitosan / agarose xerogel particles, and sieved to obtain 20-40 mesh standards Sample particles3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com