A kind of preparation method of cobalt-based catalyst for reforming hydrogen production with CO reduction modification

A cobalt-based catalyst, reforming hydrogen production technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of large particle size of cobalt species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

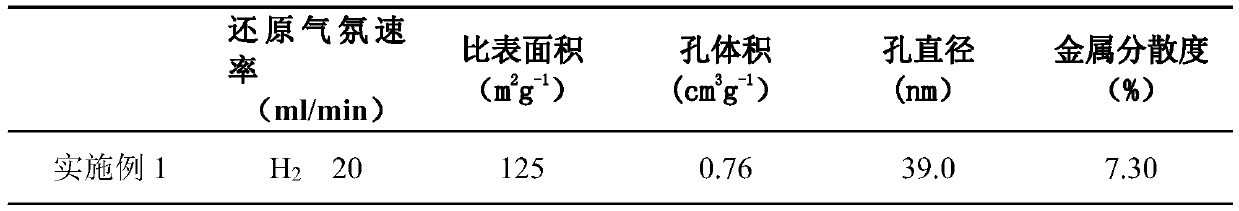

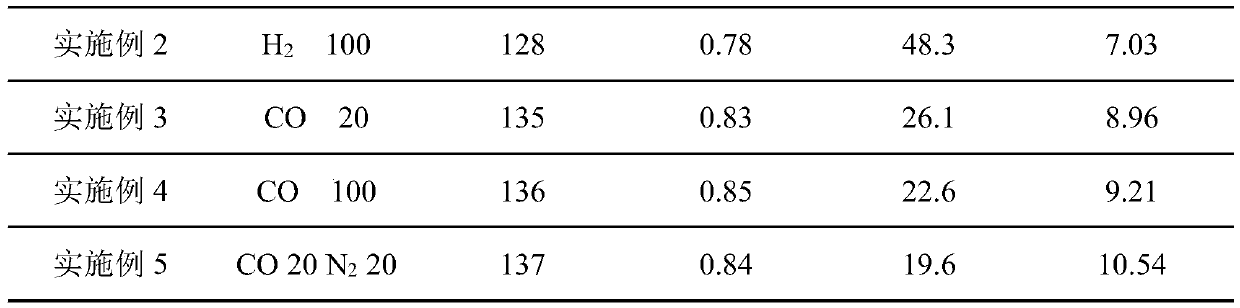

[0027] 1.H 2 Reduction treatment: Weigh 500 mg of the ground catalyst precursor, put it into the reactor, and control the introduction of H 2 The flow rate is 20ml / min, the reduction treatment is carried out at 500°C for 200min, and the hydrogen is cut off. The particle size and dispersion of metal cobalt particles are shown in Table 1.

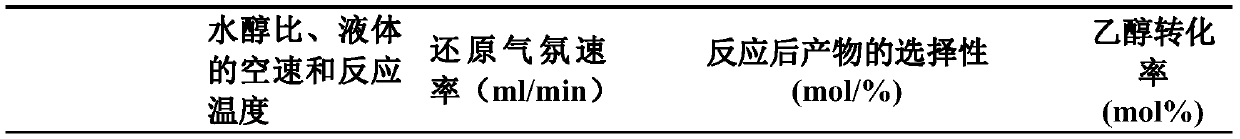

[0028] 2. Hydrogen production by steam reforming of ethanol: Introduce nitrogen, the flow rate of nitrogen gas is controlled at 80ml / min, and the aqueous ethanol solution with a molar ratio of water to ethanol of 9:1 is pumped into the reactor at a flow rate of 0.2ml / min at 500°C Under the conditions of the reaction to produce hydrogen. The reaction results are shown in Table 2.

Embodiment 2

[0030] 1.H 2 Reduction treatment: Weigh 500 mg of the ground catalyst precursor, put it into the reactor, and control the introduction of H 2 The flow rate is 100ml / min, the reduction treatment is carried out at 500°C for 200min, and the hydrogen is cut off. The particle size and dispersion of metal cobalt particles are shown in Table 1.

[0031] 2. Hydrogen production by steam reforming of ethanol: Introduce nitrogen, the flow rate of nitrogen gas is controlled at 80ml / min, and the aqueous ethanol solution with a molar ratio of water to ethanol of 9:1 is pumped into the reactor at a flow rate of 0.2ml / min at 500°C Under the conditions of the reaction to produce hydrogen. The reaction results are shown in Table 2.

Embodiment 3

[0033] 1. CO reduction treatment: Weigh 500 mg of the ground catalyst precursor, put it into the reactor, control the flow rate of CO to 20ml / min, and perform reduction treatment at 500°C for 200 minutes to cut off carbon monoxide. The particle size and dispersion of metal cobalt particles are shown in Table 1.

[0034] 2. Hydrogen production by steam reforming of ethanol: Introduce nitrogen, the flow rate of nitrogen gas is controlled at 80ml / min, and the aqueous ethanol solution with a molar ratio of water to ethanol of 9:1 is pumped into the reactor at a flow rate of 0.2ml / min at 500°C Under the conditions of the reaction to produce hydrogen. The reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com