Electric horizontal movement rotary disc trolley

A turntable and electric technology, which is applied to railway car body components, railway braking systems, brakes with pressure braking surfaces, etc., can solve the problem of difficult control of the position of the conveying trolley, failure to meet the use requirements, poor safety performance, etc. The problem is to achieve a good braking effect, reduce the distance to continue moving, and prevent collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

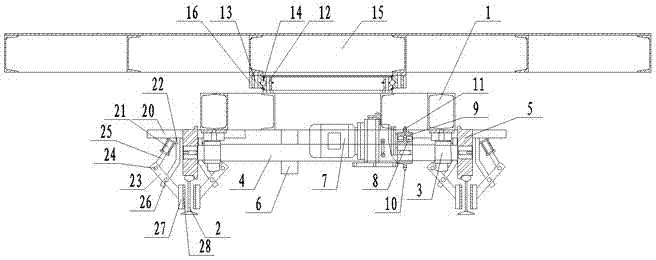

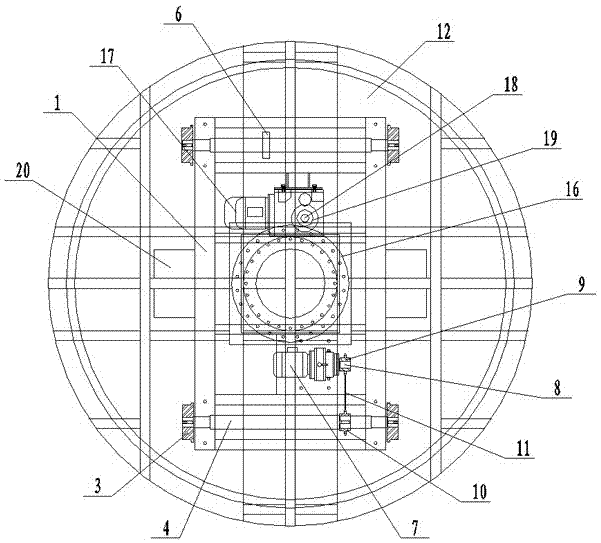

[0010] Such as figure 1 , figure 2 As shown, the electric translation turntable car includes: a vehicle frame 1 and two slide rails 2 arranged on the ground, and a drive shaft 4 is respectively arranged on the front and rear sides of the lower end of the vehicle frame 1 through the rotation of the first bearing seat 3, The two ends of the drive shaft 4 protruding from the first bearing seat 3 are respectively provided with drive rollers 5, and the drive rollers 5 are respectively slidably arranged on the slide rail 2, and a brake disc is provided on the front drive shaft 4. 6. A first servo deceleration motor 7 is provided at the lower end of the vehicle frame 1, a drive sprocket 9 is provided on the motor shaft 8 of the first servo deceleration motor 7, and a driving sprocket 9 is provided on the rear drive shaft 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com