Separation device for powder particle materials

A technology for separation equipment and powder particles, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve the problems of difficult to meet the separation requirements of large weight materials, low work efficiency, time-consuming and laborious, etc. problems, to achieve the effect of high sorting accuracy and fineness, convenient installation and maintenance, and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

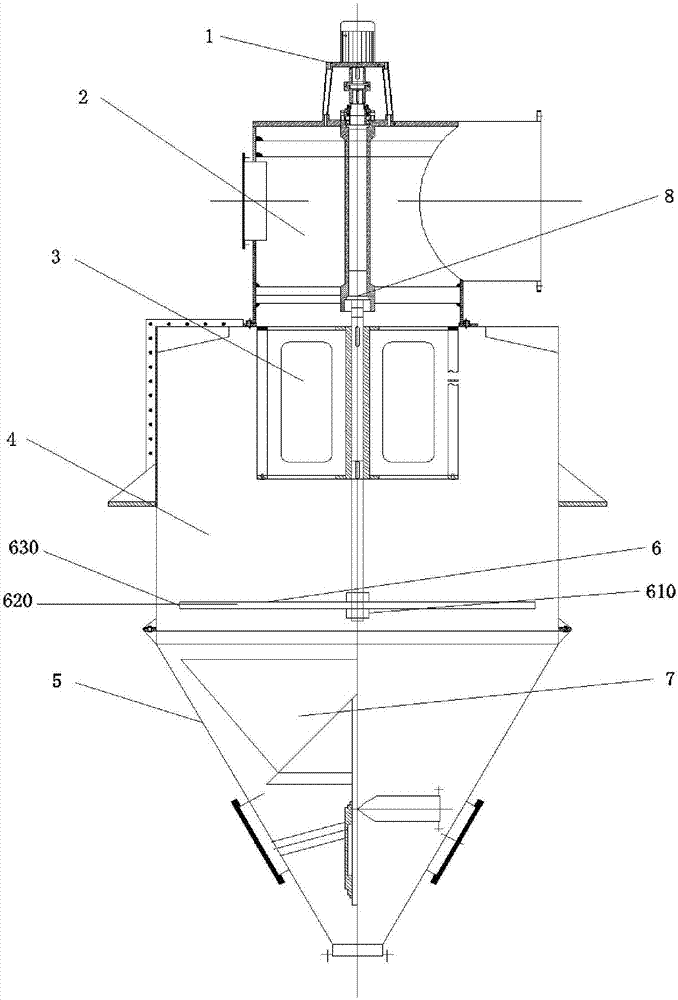

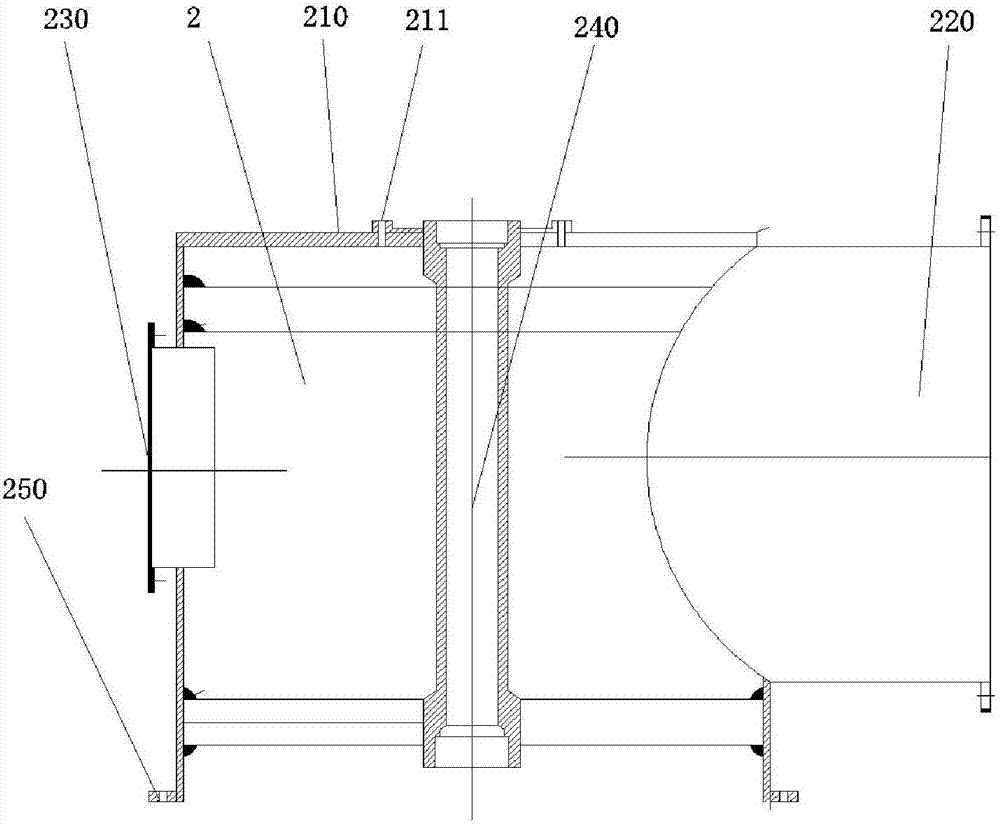

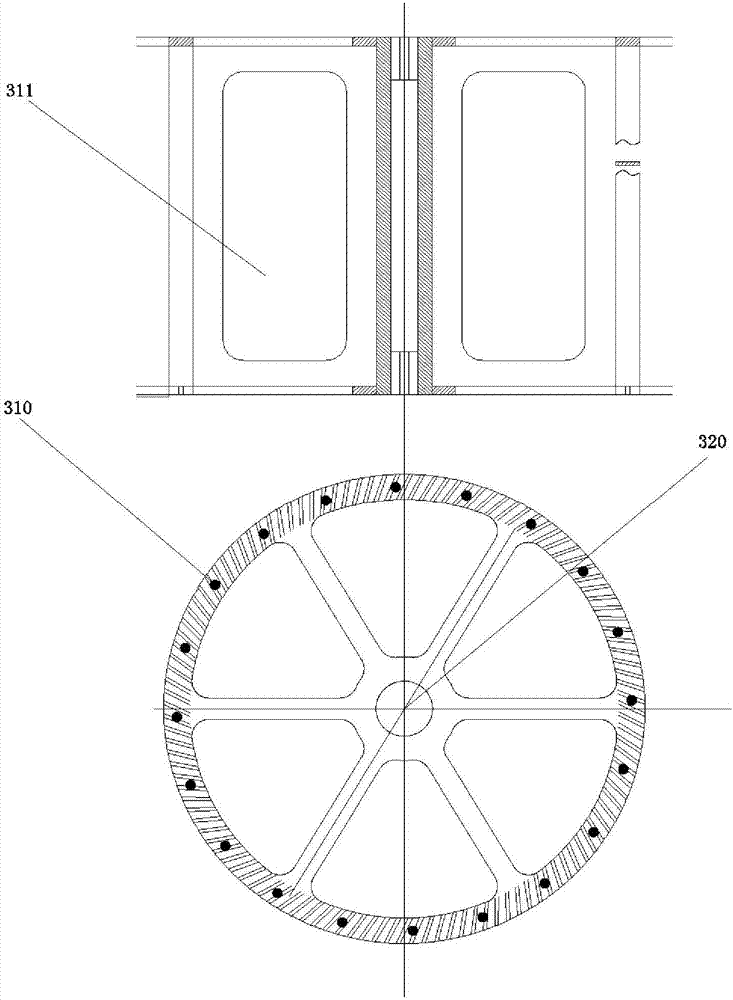

[0023] Please refer to Figure 1-Figure 5 , figure 1 The present invention provides a schematic diagram of the overall structure of a separation device for powder particle materials; figure 2 A schematic structural view of the feed cylinder is provided for the present invention; image 3 Provide the top view and front view of the separation mechanism for the present invention; Figure 4 Provide a schematic structural view of the upper cylinder for the present invention; Figure 5 A schematic structural diagram of the lower cylinder and the dust receiving mechanism is provided for the present invention.

[0024] Specifically, this embodiment provides a separation device for powder particle materials, which includes from top to bottom: drive motor mounting base 1, feeding cylinder 2, separation mechanism 3, upper cylinder 4, lower cylinder 5, filter Plate 6, dust receiving mechanism 7, and drive shaft 8; wherein, the drive motor mount 1 is fixedly installed on the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com