Manufacturing process for precision casting and sand casting mixed runner applied to casting molding

A production process and sprue technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of precise control of difficult metal melts, molten iron rushing, etc., and achieve the effect of improving the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

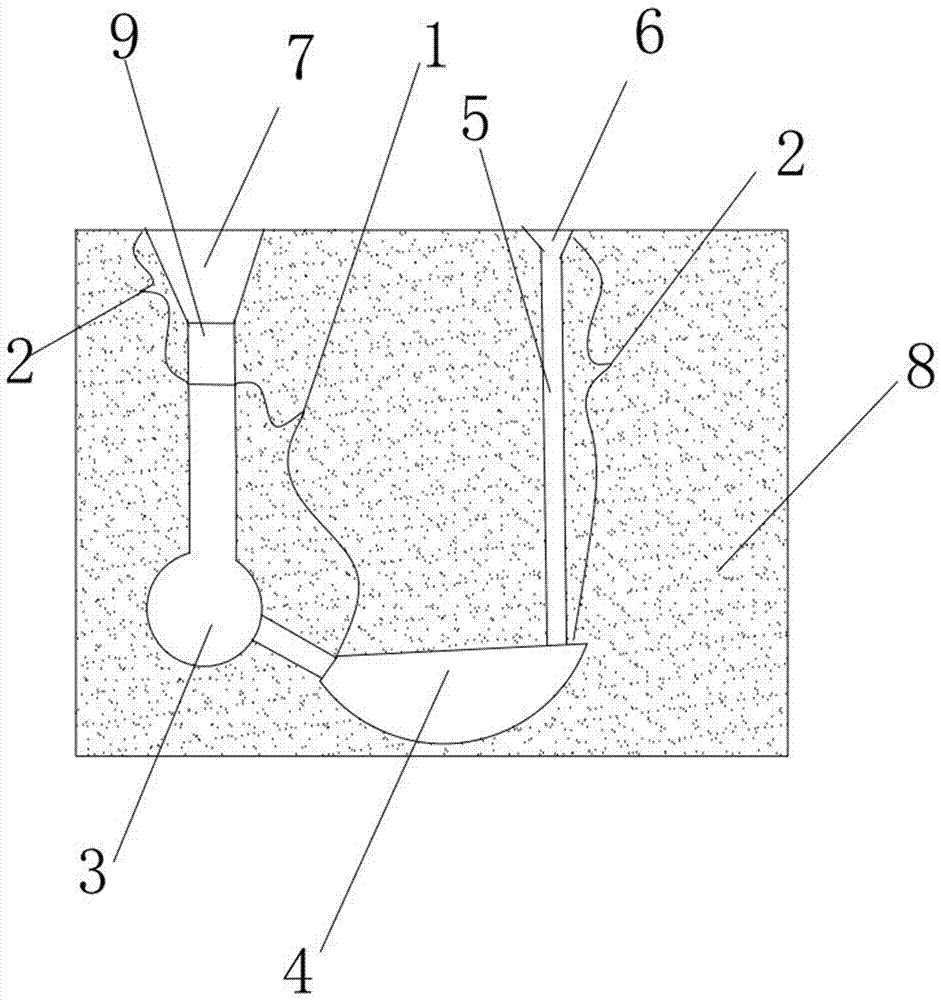

[0034] During casting, the molten metal enters the sand casting runner 2 from the sprue cup 7 of the triangular cup mouth, and then reaches the mold cavity through the precision casting runner 1. During the flow process, the buffer cavity acts as a deceleration buffer for the molten metal , when it can be seen that the molten metal emerges from the molten metal outlet 6, it can be considered that the cavity has been filled with the molten metal, and at this moment, the pouring of the molten metal is stopped.

[0035] After the molten metal cools and solidifies to form a casting, the casting is dug out from the molding sand, and then the precision casting sprue attached to the casting is knocked off to complete the casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com