Resistance spot-welding technique for end of bimetal mechanical composite pipe

A resistance spot welding and composite pipe technology, applied in resistance welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of easy to produce brittle and hard structure, high welding cost, large stress concentration at the welding toe, etc., to reduce welding Less impact on cost and welding time, performance, reduced stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

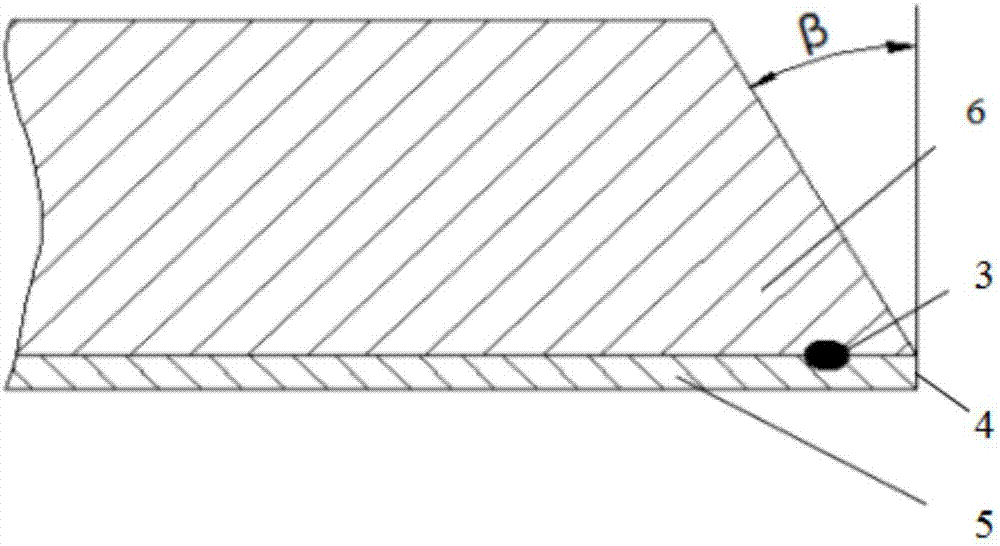

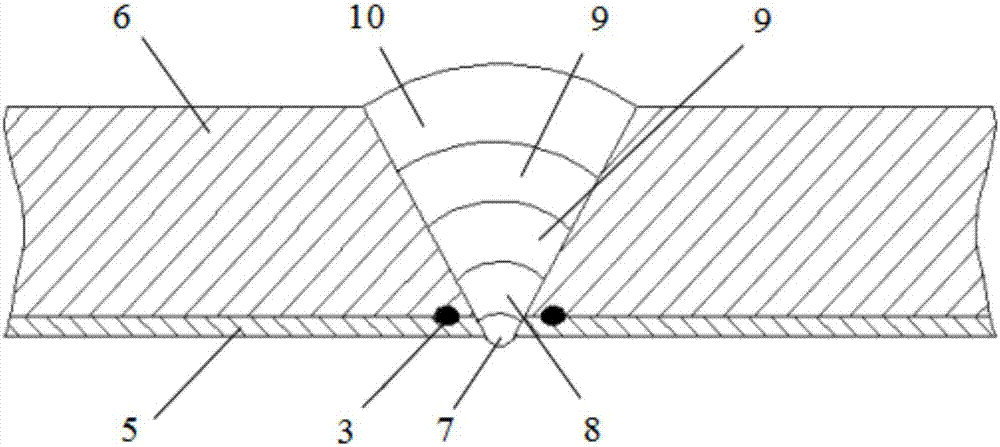

[0024] In this embodiment, the welded mechanical composite pipe 1 is composed of a stainless steel lining pipe 5 made of 316 stainless steel and a carbon steel base pipe 6 made of L415 carbon steel, and its specification is Φ355x(11+2)mm .

[0025] Step 1. Welding groove treatment, the treatment process is as follows:

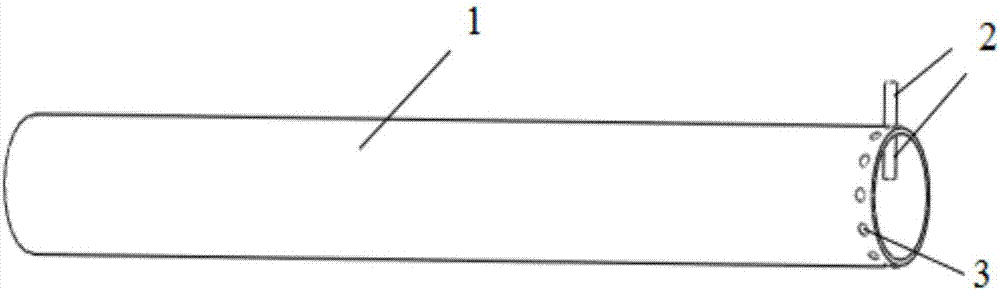

[0026] 101. Adjust the matching position of the mechanical composite tube and the electrode of the spot welding machine so that the axis of the mechanical composite tube 1 is on the same surface as the electrode 2 of the spot welding machine, and the two electrodes of the spot welding machine are respectively located inside and outside the tube, and the electrode axis The distance from the heart to the pipe end is 15mm, see figure 1 ;

[0027] 102. Use a spot welding machine to spot weld the mechanical composite pipe. The diameter of the spot welding electrode is 5mm, the electrode pressure is 10KN, the spot welding current is 32KA, and the conduction time is...

Embodiment example 2

[0037] In this embodiment, the welded mechanical composite pipe 2 is composed of a stainless steel lining pipe 6 made of 316 stainless steel and a carbon steel base pipe 5 made of 20G carbon steel, and its specification is Φ76x(7+2)mm . The difference from implementation case 1 is:

[0038] In step 101, when the spot welder spot welds, the distance between the axis of the electrode and the pipe end is 10 mm; in step 102, the spot welder is used to spot weld the mechanical composite pipe, the electrode pressure is 8KN, the spot welding current is 25KA, and the mechanical composite pipe rotates The angle is 30°.

[0039] The welding wire used in the bottom welding in step 2 is ER316L, the welding current is 70A, and the flow rate of argon gas is 9L / min. The welding wire ER316L contains the following chemical components: 0.02%C, 1.85%Mn, 0.34% by weight Si, 0.001% S, 0.015% P, 18.73% Cr, 12.50% Ni and 2.36% Mo.

[0040] The welding wire used in transition welding in step 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com