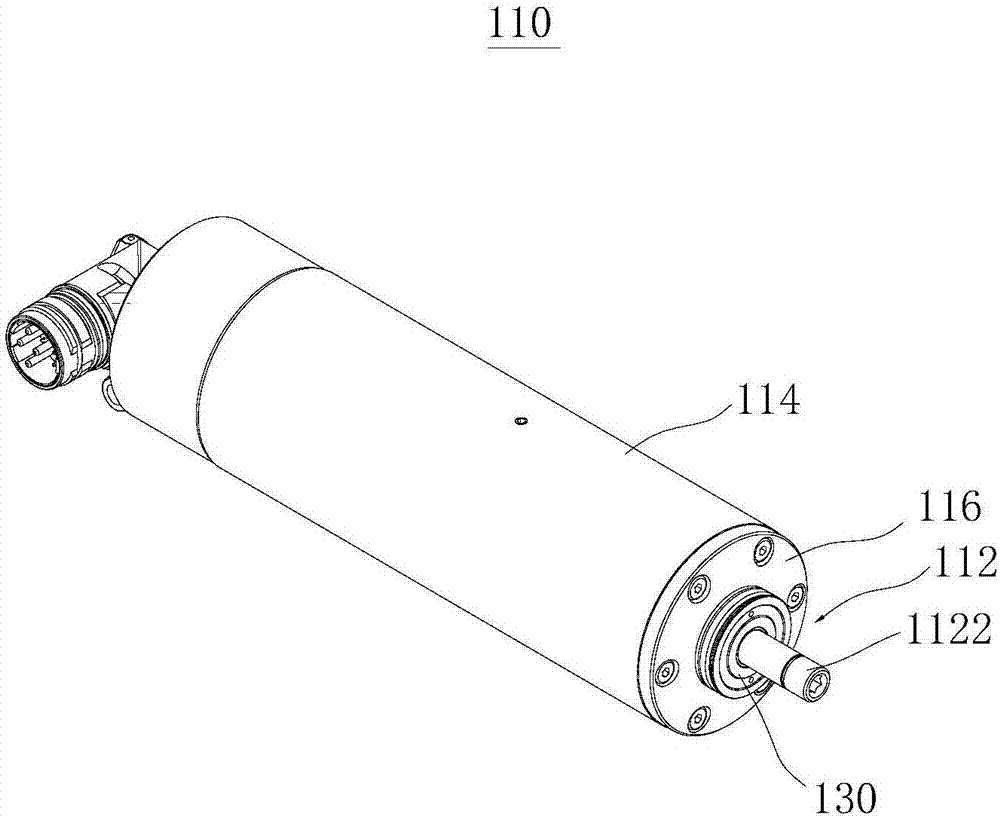

Ceramic ferrule processing device and ceramic ferrule production equipment

A ceramic ferrule and processing device technology, which is applied in metal processing equipment, grinding/polishing equipment, devices for fixing grinding wheels, etc., can solve problems such as grinding ceramic ferrules, and achieve the effect of improving verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

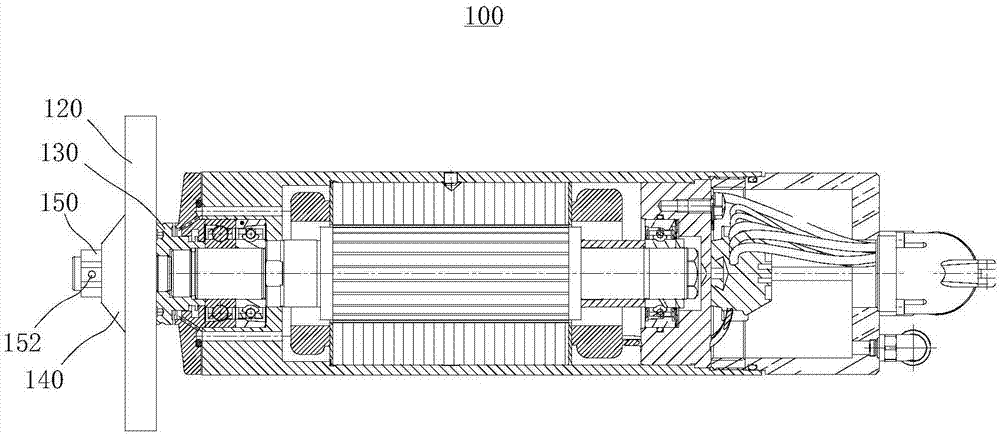

[0057] This embodiment provides a ceramic ferrule production equipment 200, the ceramic ferrule production equipment 200 includes a fixed frame and the ceramic ferrule processing device 100 in Embodiment 1 or its modified embodiment, the housing 114 of the motor 110 and the fixed The rack is fixedly connected.

[0058] The specific structure of the fixing frame can be designed according to the actual situation, as long as the motor 110 can be reliably fixed. It will not be described in detail in this embodiment.

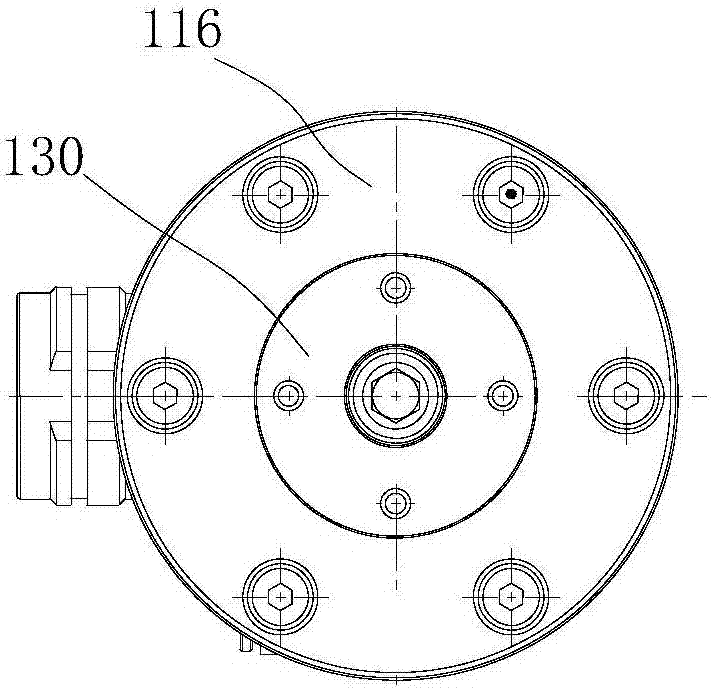

[0059] When the entire ceramic ferrule production equipment 200 is processing the outer circle of the ceramic ferrule, the compressed air source in the plant is connected to the air hole 1162 of the end cover 116 through the air pipe. After the compressed air source is turned on, the compressed air enters the end cover through the air hole 1162 116 and the first positioning plate 130 directly in the annular groove, and the movement direction of the airflow is set at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com