Auxiliary skimming shallow air floatation machine

A shallow air and flotation technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of slow rotation, affecting the cleaning effect, sedimentation or diffusion, etc., to improve the treatment effect, improve efficiency, and reduce disturbance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

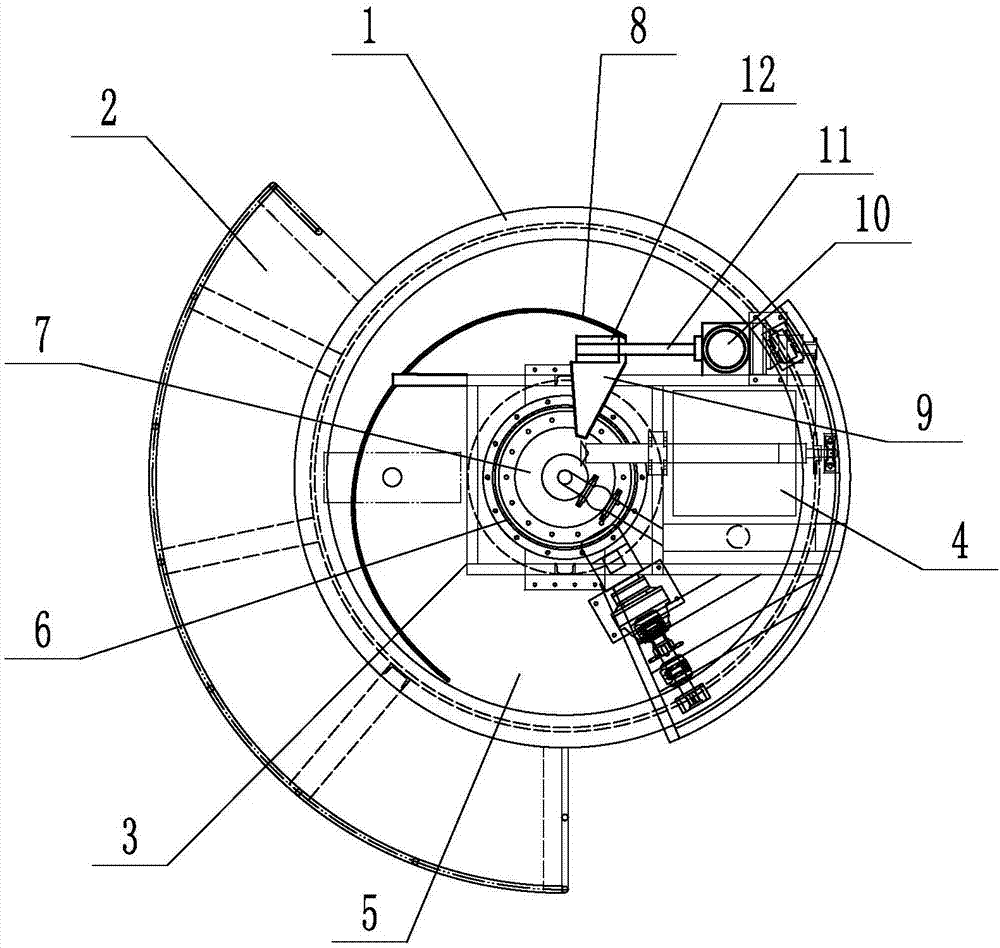

[0015] like figure 1 As shown, the present invention comprises a pool body 1, a walking platform 2 arranged on the side wall of the pool body 1, a walking frame 3 arranged at the upper end of the pool body 1, the upper end of the walking frame 3 is provided with a skimming device 4, and the pool The inside of the body 1 is provided with a sewage tank 5 , the inside of the sewage tank 5 is provided with a clean water tank 6 , and the inside of the clean water tank 6 is provided with a scum tank 7 .

[0016] The upper end of the sewage tank 5 is provided with a deflector 8 fixed on the lower end of the walking frame 3, and the front end of the deflector 8 is fixedly connected with a diversion groove 9, and the end of the diversion groove 9 extends to the bottom of the scum tank 7. upper end.

[0017] The scum skimming device 4 includes a driving reduction motor 10 , the right output end of the motor 10 is connected with a scum skimming dial 12 through a rotating shaft 11 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com