Preparation method of photo-crosslinking polyvinyl alcohol/nanocrystalline cellulose PVA/CNC compound hydrogel

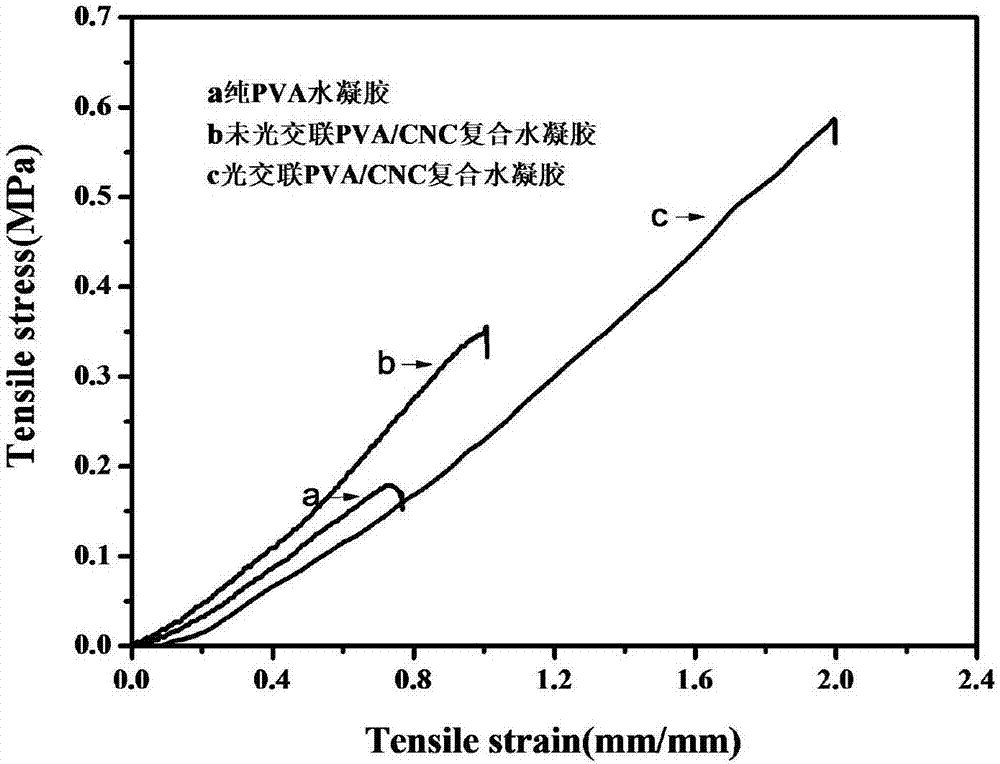

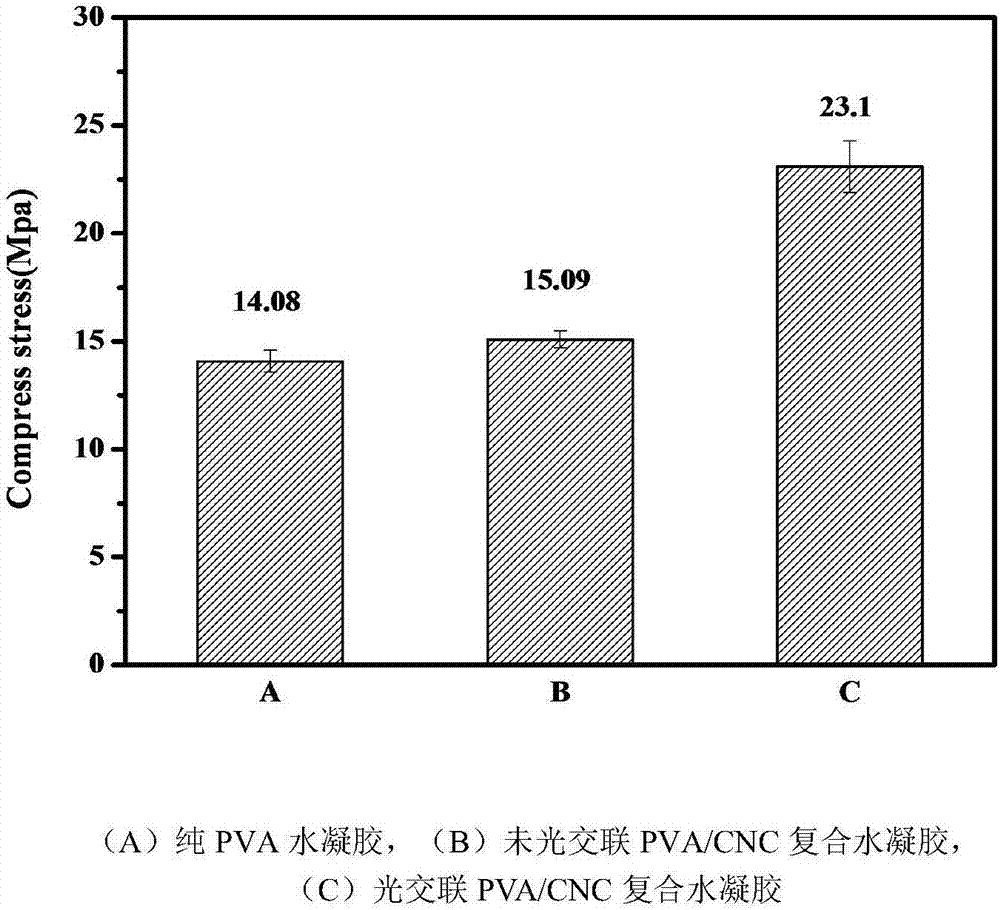

A technology of nanocrystalline cellulose and composite hydrogel, which is applied in the field of light-cured composite materials enhanced and toughened by adding a photocrosslinking agent, which can solve the problems of low mechanical properties of pure PVA hydrogel and achieve excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of PVA / CNC mixed solution: Dissolve CNC in deionized water to prepare a suspension with a mass fraction of 1%, and disperse it ultrasonically for 30 minutes in a 100W ultrasonic cleaning machine. Take 3g of PVA and 34.5mL of deionized water in a three-neck flask, stir at 90°C for 2h, after completely dissolving, add 0.02g of CNC, and continue stirring to obtain a PVA / CNC mixed solution.

[0023] (2) Preparation of photocrosslinking PVA / CNC mixed solution: Cool the above step (1) PVA / CNC mixed solution to 60°C, cool down to 60°C, add 0.15g of photocrosslinking agent MBA (N,N'-sub Methylbisacrylamide), after stirring until uniform, add 0.09g of photoinitiator 2959 (2-hydroxy-4-(2-hydroxyethoxy)-2-methylbenzene) and stir for 1h in shading, after standing for defoaming Pour it into a petri dish, and transmit it 6 times at 2 cm / min under a F300 ultraviolet lamp (Fusion UV systems. USA) to obtain a photocrosslinked PVA / CNC mixed solution.

[0024] (3) Prepara...

Embodiment 2

[0026] (1) Preparation of PVA / CNC mixed solution: Dissolve CNC in deionized water to prepare a suspension with a mass fraction of 1%, and disperse it ultrasonically for 30 minutes in a 100W ultrasonic cleaning machine. Take 3g of PVA and 34.5mL of deionized water in a three-neck flask, stir at 90°C for 2 hours, after completely dissolving, add 0.03g of CNC, and continue stirring to obtain a PVA / CNC mixed solution.

[0027] (2) Preparation of photocrosslinking PVA / CNC mixed solution: Cool the above step (1) PVA / CNC mixed solution to 60°C, cool down to 60°C, add 0.30g of photocrosslinking agent MBA (N,N'-sub Methyl bisacrylamide), after stirring until uniform, add 0.15g of photoinitiator 2959 (2-hydroxy-4-(2-hydroxyethoxy)-2-methylbenzene) and stir for 1h in shading, after standing for defoaming Pour it into a petri dish, and irradiate it under UV-1000IWATA ultraviolet point light source for 300s to obtain a photocrosslinked PVA / CNC mixed solution.

[0028] (3) Preparation of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap