Transitional flow channel structure of multi-stage centrifugal pump and design method of transitional flow channel structure

A technology of transition flow channel and structure design, which is applied to the components, pumps, and pump components of the pumping device for elastic fluid, which can solve the problem of the uncompact structure of the pump body, the large size of the pump body, and the increase of pump cavitation, etc. problem, to achieve the effect of compact structure, small size and uniform flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

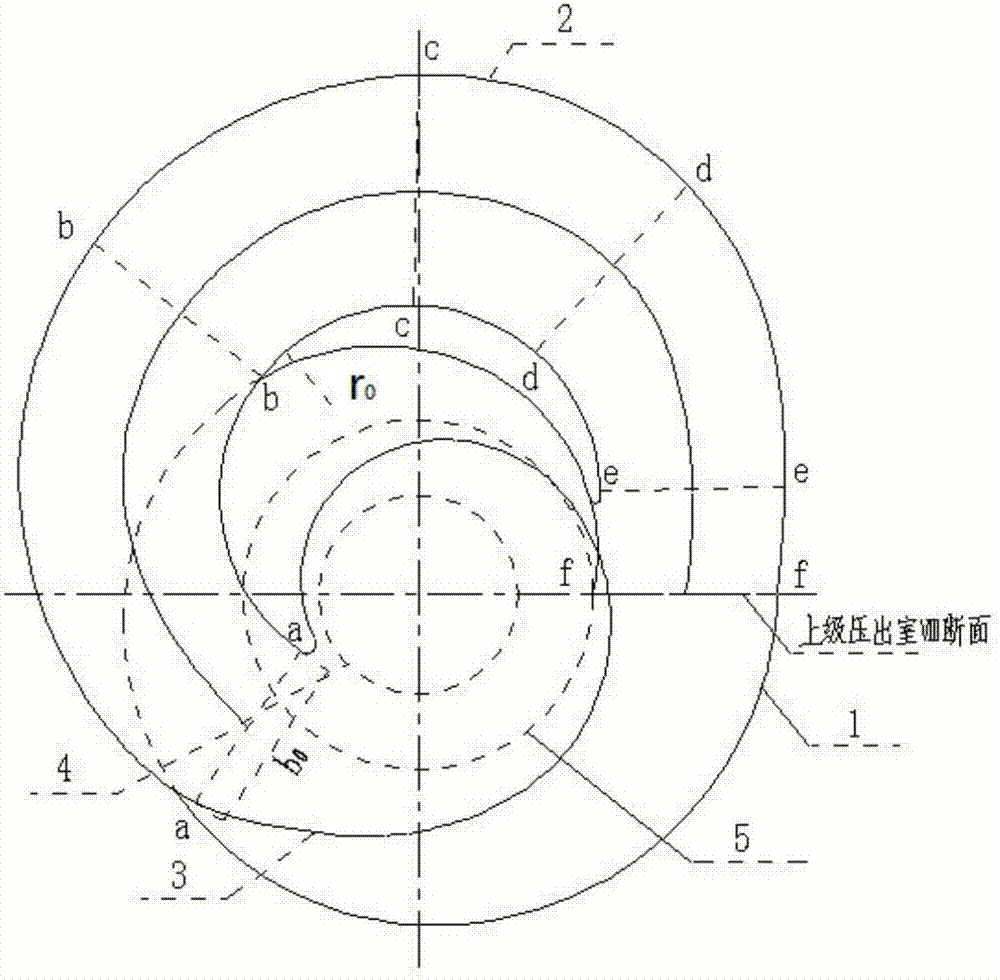

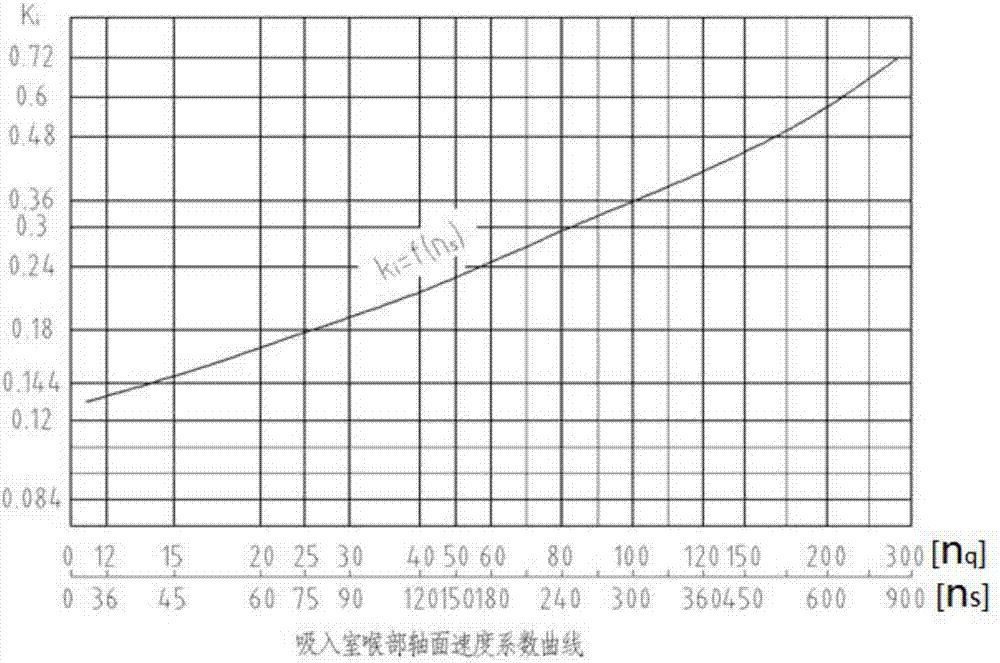

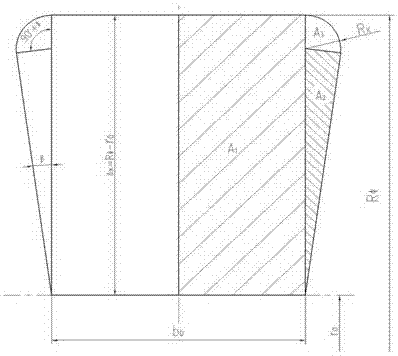

[0035] A transition channel structure of a multi-stage centrifugal pump, comprising multi-stage transition channels spliced together, each transition channel includes a pressure water chamber 1, a diffusion elbow 2, and a water absorption chamber 3, and the pressure water chamber 1 and the water absorption chamber 3 Connected, the outside of the water absorption chamber 3 is provided with a diffusion elbow 2; the water inlet of the diffusion elbow 2 is connected with the pressure water chamber 1 of the same level, and the water outlet of the diffusion elbow 3 is connected with the water absorption chamber 3 of the next level, and the water absorption chamber 3 It is spiral, and the diffuser elbow 3 is annular. The arc angle Φ of the diffusion elbow 3 is 180-270°. The reference circle 4 of the water absorption chamber and the reference circle 5 of the pressure water chamber are arranged concentrically. The outer edge of the annular diffuser elbow 3 is formed by excessive spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com