Under-hole in-situ three-dimensional static load-vertical side friction force testing device for rock and earth mass

A side friction resistance, testing device technology, applied in the direction of measuring device, using stable shear force to test material strength, using stable tension/pressure test material strength and other directions, can solve friction resistance and tip resistance unclear, The penetration mechanism is unclear, the lack of simple and easy-to-use measurement equipment, etc., to achieve the effect of accurate measurement results and rapid testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

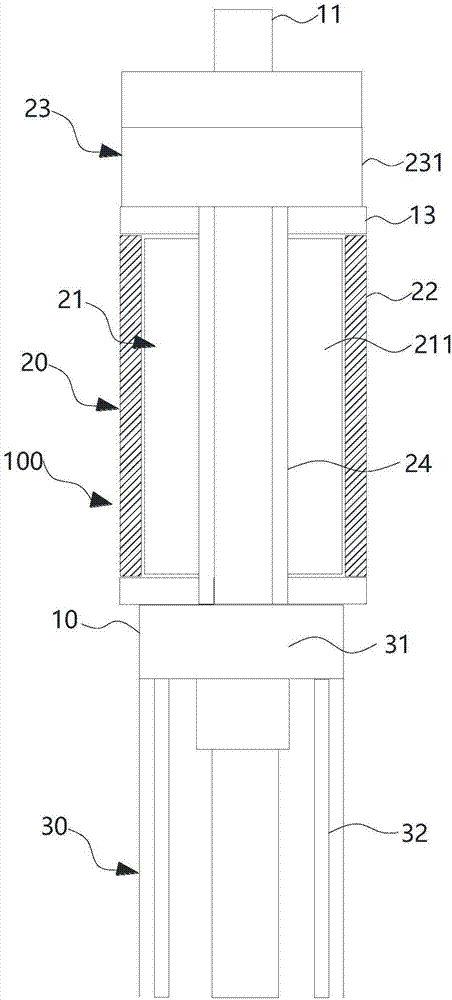

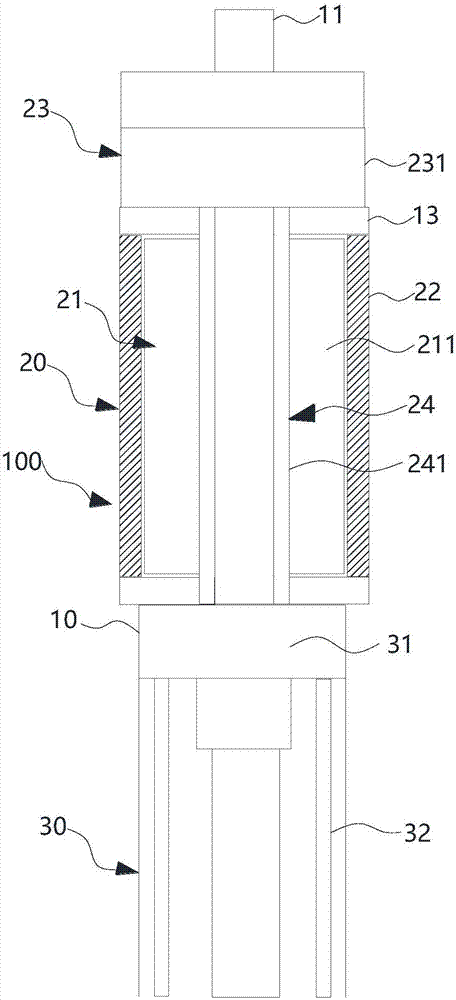

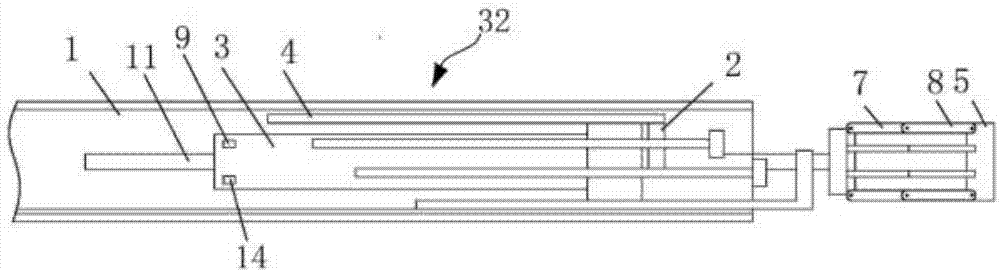

[0055] Such as figure 1 , 2 As shown, the in-situ three-dimensional static load-vertical side friction resistance test device 100 under the rock and soil body hole according to an embodiment of the present invention generally includes a frame 10 that can be accessed in an underground borehole by a cable. 10 is equipped with a lateral experiment part 20 and a vertical experiment part 30, and a test unit for receiving and processing the measurement data of the lateral experiment part 20 and the vertical experiment part 30.

[0056] The frame 10 can be a cylindrical frame structure, and a corresponding protective shell can be installed on the outside, and different test components can be installed on the inside through various frames.

[0057] The lateral experiment part 20 is installed on the top of the frame 10, and is used to realize the lateral static load and the vertical side frictional resistance experiment under the hole. A plurality of arc-shaped reaction force plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com