Type C secondary flow passage method for power plant main system

A technology for the main system and power plant, applied in the direction of measuring only current, measuring current/voltage, phase angle between voltage and current, etc. The effect of saving secondary flow time, saving working time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

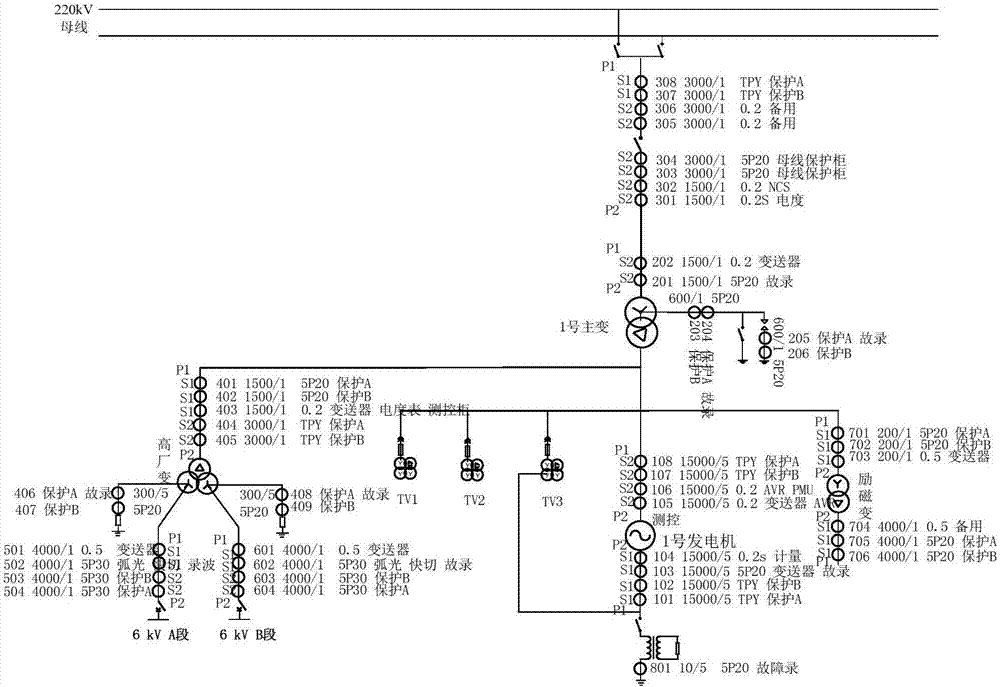

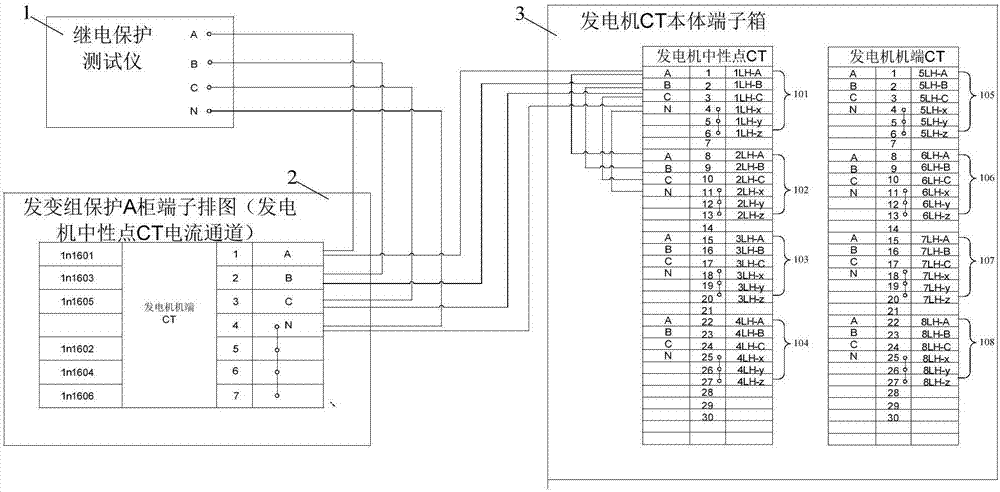

[0044] The technical solution of the present invention will be described in further detail below with reference to the accompanying drawings.

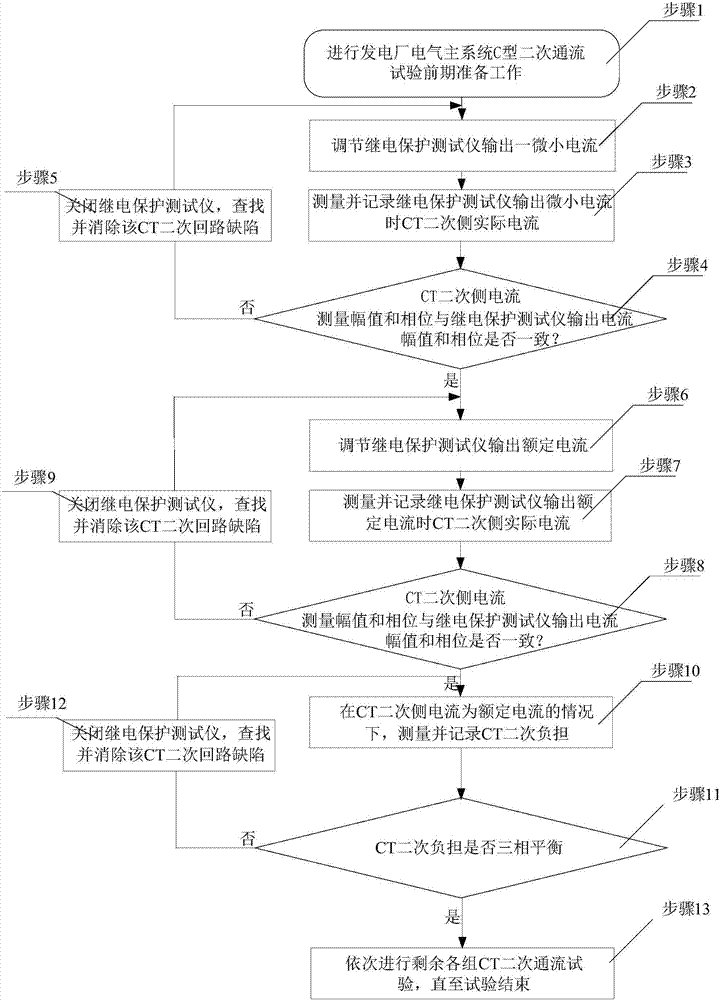

[0045] Such as figure 1 , figure 2 and image 3 As shown, a kind of power plant electric main system C-type secondary circulation method of the present invention comprises the following steps:

[0046] 1) Carry out preparatory work for the C-type secondary flow test, and enter step 2) after all preparatory work is completed;

[0047] 2) Turn on the power supply of the relay protection tester, adjust the output of the relay protection tester to 0.1 times the rated current, and enter step 3);

[0048] 3) Measure and record the actual current on the secondary side of the CT when the relay protection tester outputs 0.1 times the rated current, and then enter step 4);

[0049] 4) Judging whether the amplitude and phase of the CT secondary side current measurement are consistent with the output current amplitude and phase of the relay p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com