Self-lubricating slide plate

A sliding bed plate and self-lubricating technology, which is applied in roads, tracks, buildings, etc., can solve the problems of large maintenance and maintenance workload of applying lubricating oil, insignificant resistance reduction, and high cost of roller devices, so as to reduce conversion failure and maintenance The effect of maintenance workload, convenient maintenance and repair, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

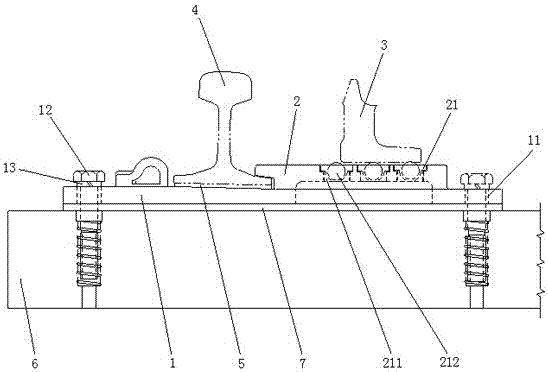

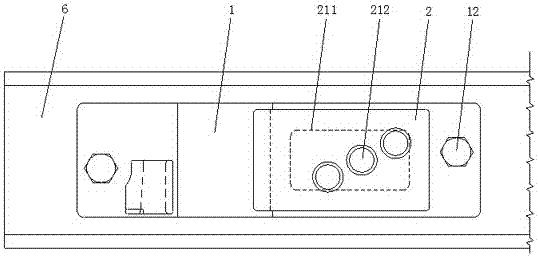

[0020] Such as figure 1 , 2 As shown, the self-lubricating sliding bed of the present invention includes a sliding bed body 1 , a sliding bed platform 2 , a point rail 3 and a basic rail 4 .

[0021] The sliding bed body 1 is a rectangular plate structure as a whole, and its two ends along the length direction are symmetrically provided with nail holes 11, and the sliding bed body 1 and the rubber backing plate 7 are fixed on the On the switch sleeper 6; wherein, the rubber backing plate 5 is located between the slide bed body 1 and the switch sleeper 6.

[0022] The sliding bed platform 2 is arranged on the top surface of one end of the sliding bed board body 1, and a self-lubricating area 21 is provided in the middle, and the self-lubricating area 21 is provided with a steel ball assembly 211, which is a cup structure and passes through Correspondingly embedded into the surface of the slide table 2, steel balls 212 are embedded in the steel ball assembly 211, and grease is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com