A compressed air cycle power device

A technology of circulating power and compressed air, which is applied to components of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc., can solve the problems of reduced utilization of compressed air and waste of energy, and achieve reduction of emissions, The effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

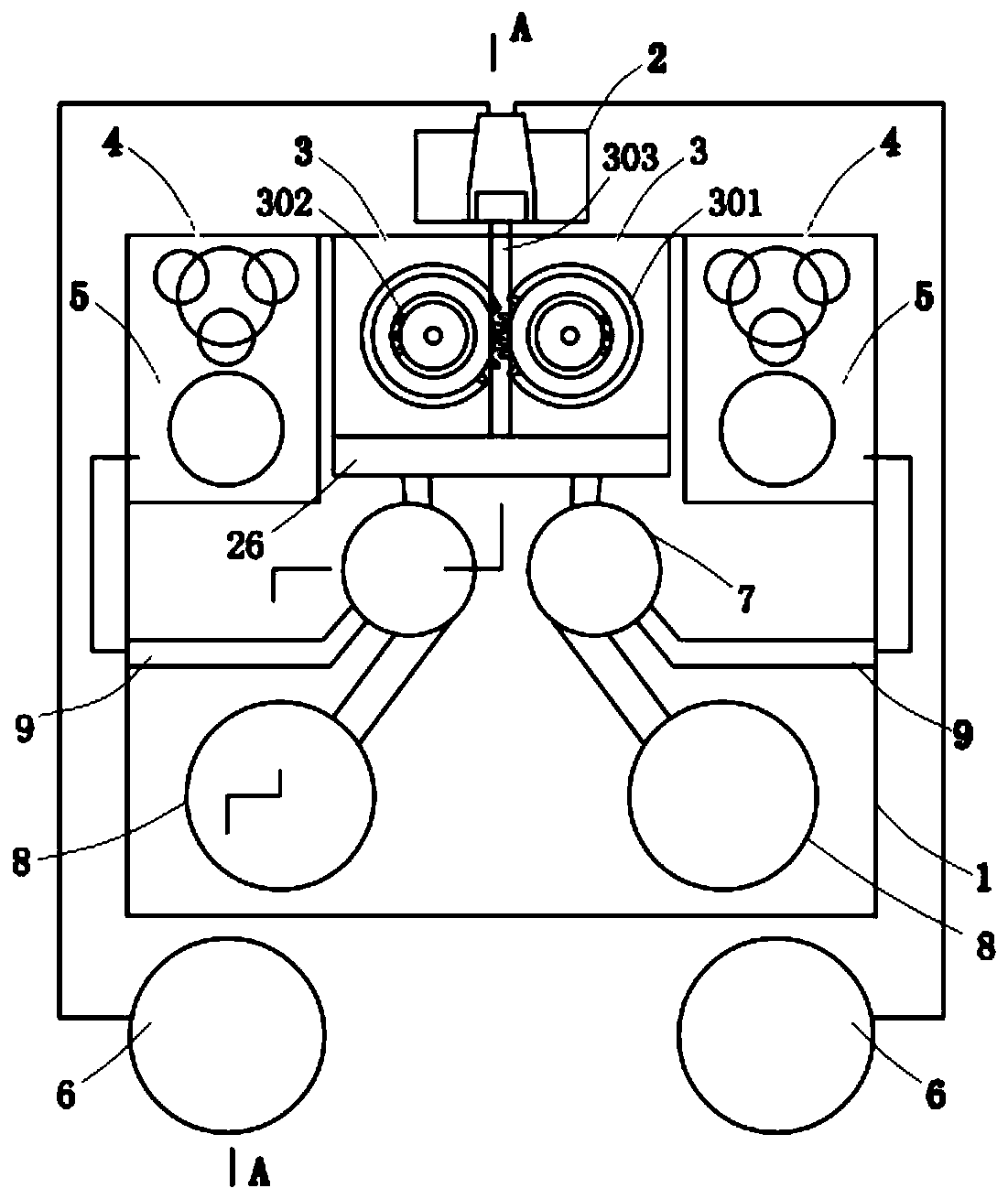

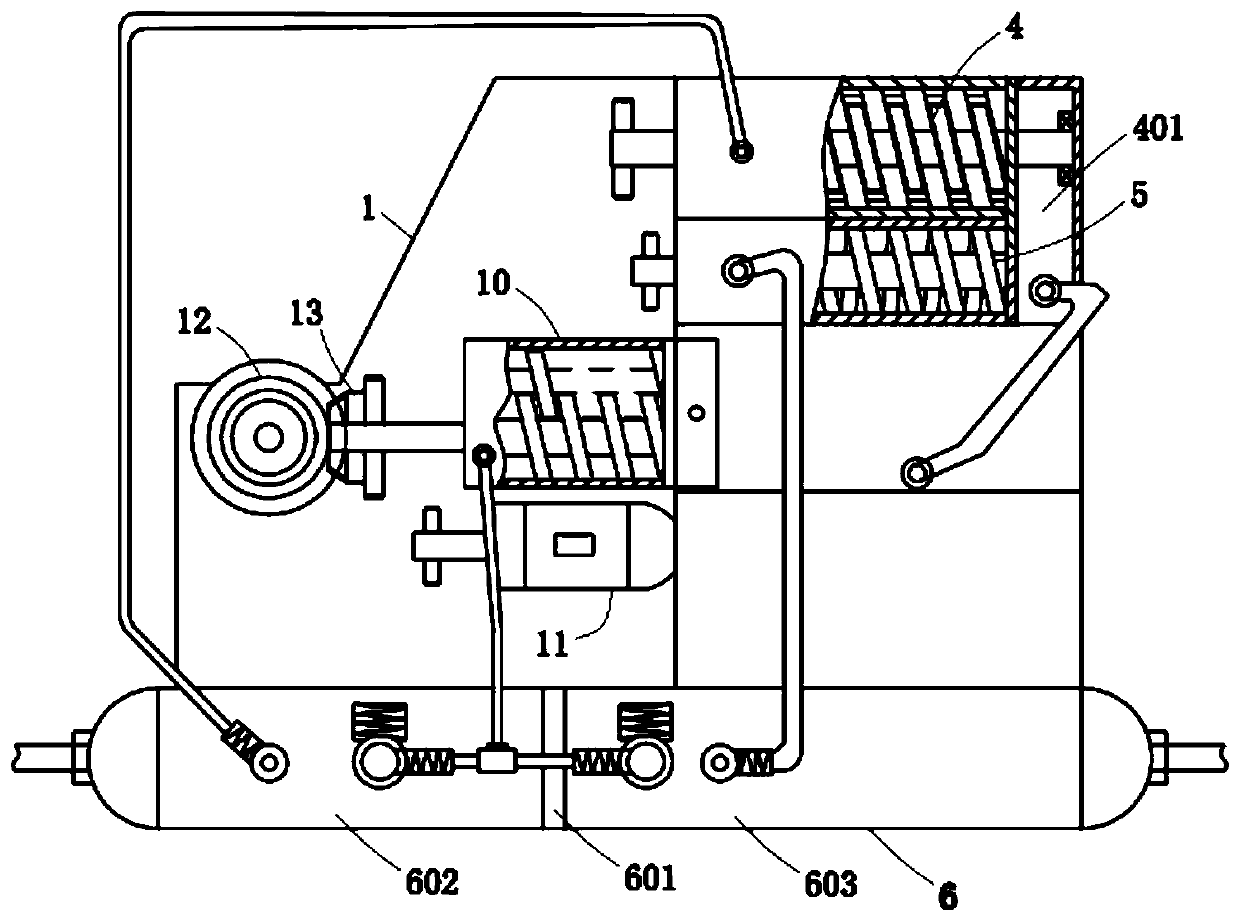

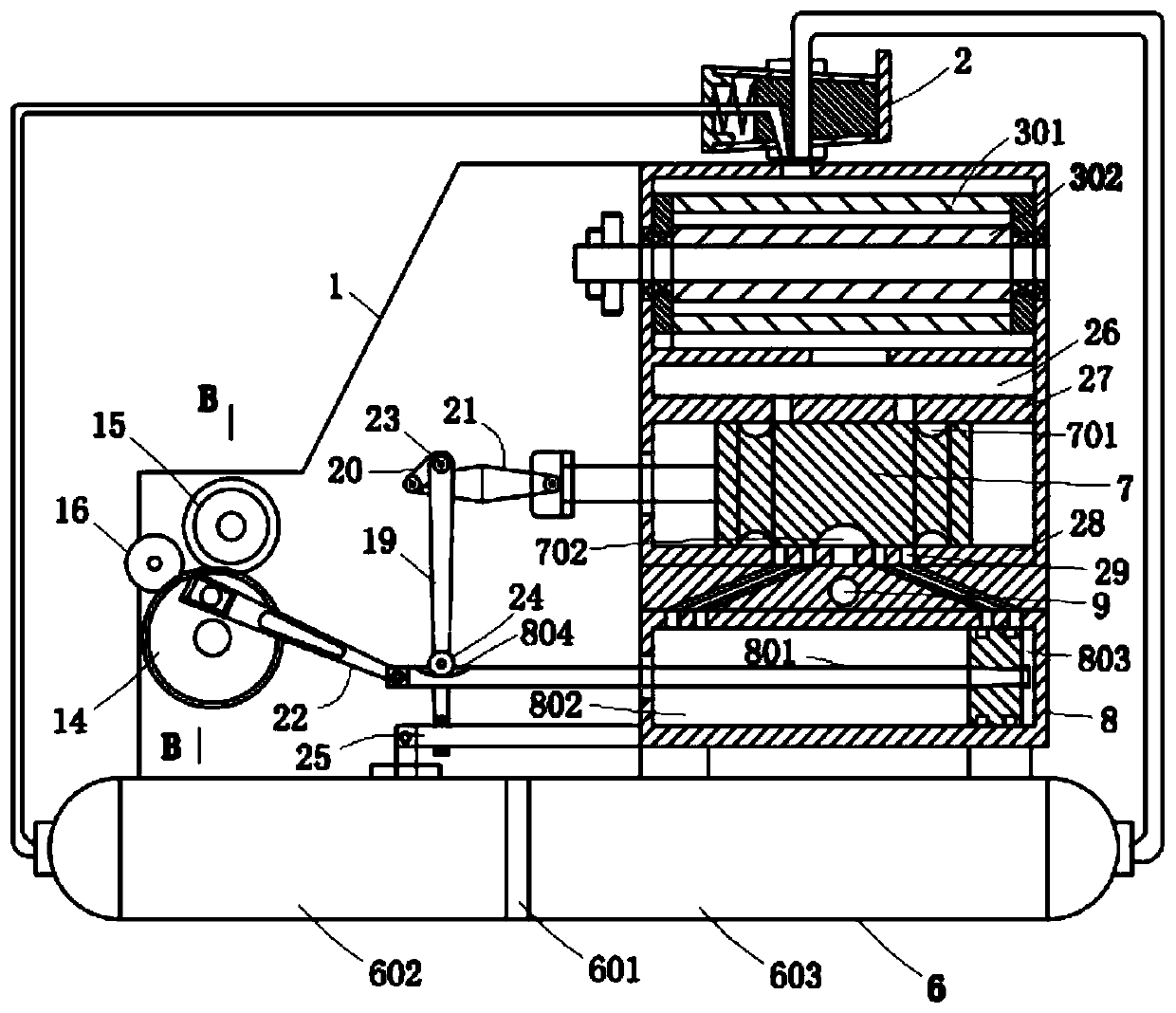

[0023] Such as Figure 1 to Figure 4As shown, the present invention provides a compressed air cycle power device, the cycle power device includes a frame 1, and an air storage tank 6 is fixedly installed on the frame 1, and a partition 601 is arranged in the gas storage tank 6, and the partition 601 will The internal space of the air storage tank 6 is divided into a high-pressure chamber 602 and a low-pressure chamber 603. The pressure of the compressed air in the high-pressure chamber 602 is higher than the pressure of the compressed air in the low-pressure chamber 603. The pressure difference needs to be set according to the needs. Here, usually The pressure in the high-pressure chamber 602 is 15 kilograms, and the pressure in the low-pressure chamber 603 is 10 kilograms. The air mixing valve 2 is arranged on the frame 1. One air inlet of the air mixing valve 2 is connected to the high-pressure chamber 602, and the other air inlet is connected to the air inlet. The low-press...

Embodiment 2

[0028] Such as Figure 1 to Figure 4 As shown, the present invention provides a compressed air cycle power plant, the structure of which is basically the same as that of Embodiment 1. The difference is that on the basis of Embodiment 1, the following features are added, and further improvements are made to improve performance of the present invention.

[0029] An external force motor 11 is installed on the frame 1, and the external force motor 11 is connected to the screw shaft of the screw air compressor 10 through a clutch. The function of the external force motor 11 is to start the external force motor 11 to drive the screw air compressor 10 to work before work , respectively inflate the high-pressure chamber 602 and the low-pressure chamber 603 of the air storage tank 6, so that the pressure difference between the high-pressure chamber 602 and the low-pressure chamber 603 is formed. After reaching the pressure difference, the external force motor 11 and the screw air compr...

Embodiment 3

[0031] Such as Figure 1 to Figure 4 As shown, the present invention provides a compressed air cycle power plant, the structure of which is basically the same as that of Embodiment 1. The difference is that on the basis of Embodiment 1, the following features are added, and further improvements are made to improve performance of the present invention.

[0032] There are two gas storage tanks 6, the high-pressure chambers 602 of the two gas storage tanks 6 are connected, and the low-pressure chambers 603 of the two gas storage tanks 6 are connected. On the one hand, the equipment is symmetrical, and on the other hand, the gas storage capacity can be relatively increased. Further improve the energy conversion rate of compressed air.

[0033] When in use, first artificially create a pressure difference, start the external force motor 11, respectively inflate the high-pressure chamber 602 and the low-pressure chamber 603 of the air storage tank 6, so that the pressure of the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com