Six-dimensional force sensor with elastomer structure

A six-dimensional force sensor and elastic body structure technology, applied in the field of sensors, can solve the problems of restricting measurement accuracy, affecting force feedback and force control performance, and achieve the effects of improving measurement accuracy, reducing measurement error, and simplifying decoupling algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

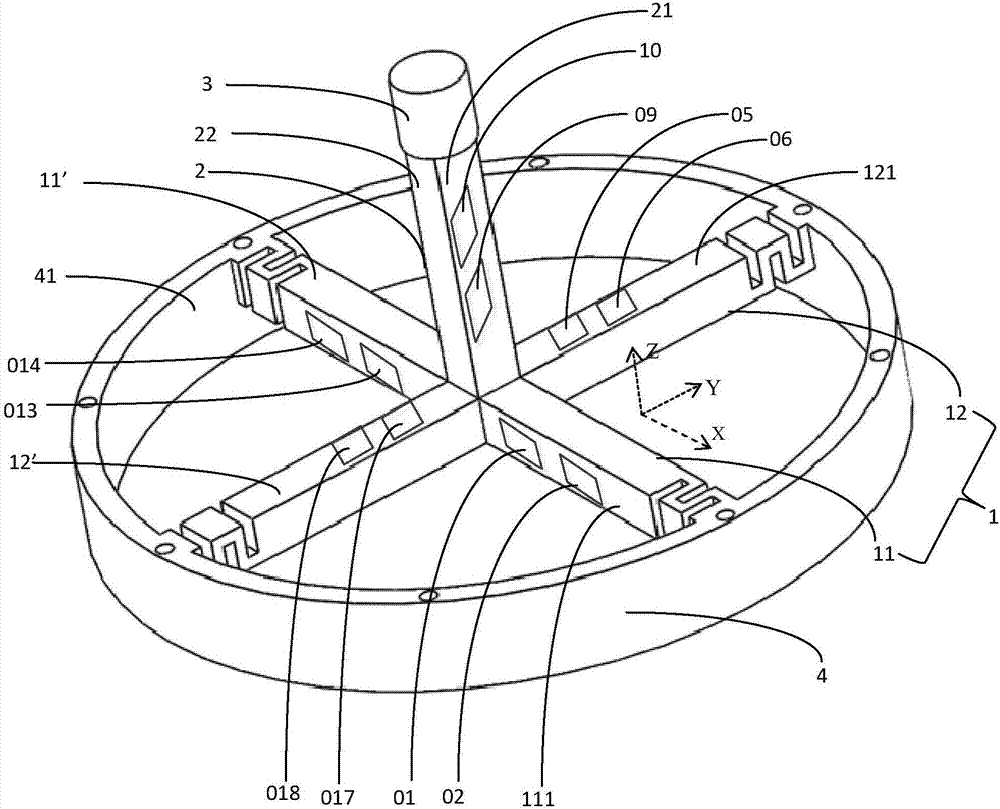

[0013] Such as figure 1 As shown, in order to facilitate the description of the direction, a spatial Cartesian coordinate system is established as shown in the figure.

[0014] Such as figure 1 As shown, the six-dimensional force sensor with an elastic body structure includes a horizontal elastic beam 1, a central vertical elastic beam 2, a loading shaft 3 and an outer ring fixing platform 4, the horizontal elastic beam 1 is a cross-shaped structure, and the horizontal elastic beam 1 includes Four equal-length branches, one end of the central vertical elastic beam 2 is fixed at the center of the cross-shaped structure of the horizontal elastic beam 1, and is perpendicular to the surface where the cross-shaped structure is located, and the loading shaft 3 is installed on the central vertical elastic beam 2 The other end of the outer ring fixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com