Waste mulching film recycling machine for cultivating soil

An all-in-one machine and plastic film technology, applied in agricultural machinery and implements, agriculture, shovels, etc., can solve the problems of tobacco plants being susceptible to root and shin diseases, incomplete treatment and recovery of residual film, and waste plastic film occupying a large space, etc. The effect of peeling off the film, rising labor prices, and facilitating loading and unloading and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

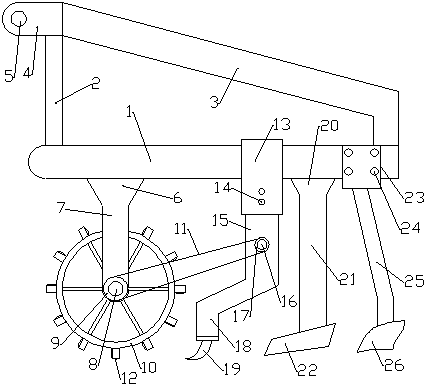

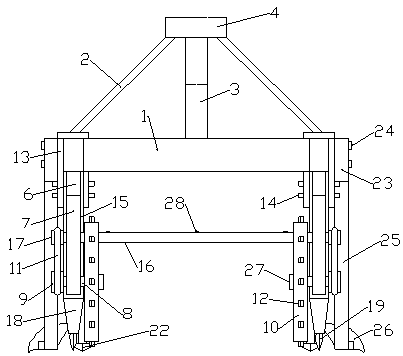

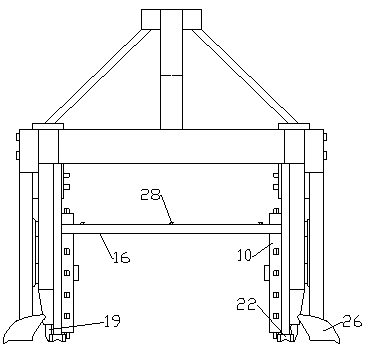

[0021] Such as figure 1 , 2 As shown in , 3 and 4, an all-in-one machine for recycling waste plastic film into cultivating soil, including a support 1, a cable-stayed support frame 2 installed on the support 1, and a longitudinal support frame 3 connected to the top of the cable-stayed support frame 2 and the support 1 , the connection frame 4 that is installed on the end of the cable-stayed support frame 2 and the longitudinal support frame 3 is provided with a hanging hole 5, the front end of the lower part of the support 1 is provided with a film-removing device, and the rear end of the film-removing device is provided with a cultivating device , the rear end of the cultivating device is provided with a device for cultivating soil, and the film removing device includes a wheel bracket 7 installed on the bottom of the bracket 1, and the inner side of the bottom of the wheel bracket 7 is equipped with a walking wheel 10 through a short wheel shaft 8, and outside the short whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com