Seed threshing apparatus

A kind of equipment and seed technology, which is applied in the field of seed threshing equipment, can solve the problems of time-consuming, low efficiency, and the size difference of different weed seeds, etc., and achieve the effect of expanding the feeding port area, improving adaptability, and high threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

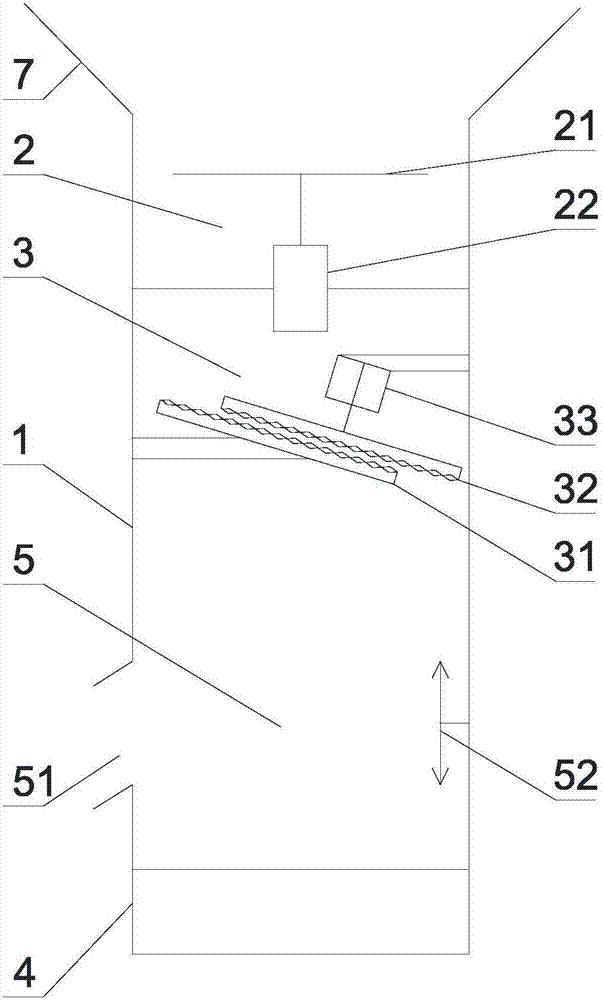

[0051] like figure 1 As shown, a kind of seed threshing equipment provided by Embodiment 1 of the present invention includes a cylinder 1, and also includes a shearing device 2, a peeling device 3, and a separation device 5 sequentially arranged in the cylinder 1; wherein, the shearing device 2 It includes a first driving mechanism and a shearing mechanism, the first driving mechanism is fixed on the cylinder body 1, and the shearing mechanism is in transmission connection with the first driving mechanism; the peeling device 3 includes a second driving mechanism and a kneading mechanism, and the second driving mechanism is fixed on On the barrel 1, the kneading mechanism is connected to the second drive mechanism in transmission; the separation device 5 includes a blower mechanism and a lead-out mechanism, the blower mechanism is fixed on the side wall of the barrel 1, and the lead-out mechanism is arranged on the other side of the barrel 1. on the side wall. Further, the sto...

Embodiment 2

[0066] The essential difference between the second embodiment and the first embodiment is that: an adjustment bracket and a collection mechanism are also provided.

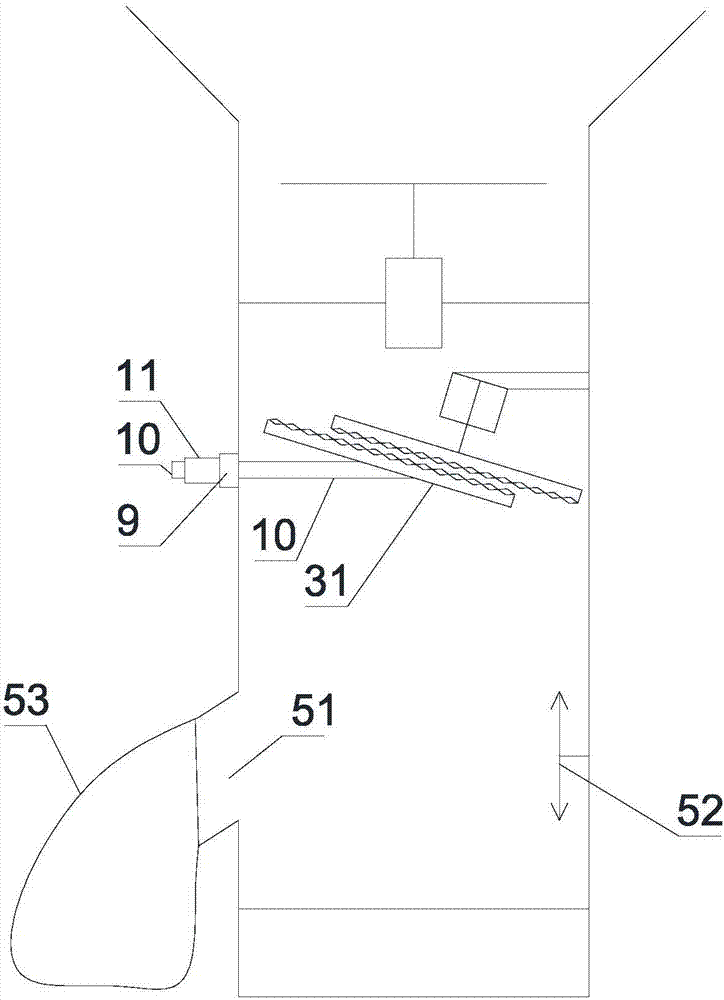

[0067] like figure 2 As shown, the seed threshing equipment provided by Embodiment 2 of the present invention has a main structure similar to that of Embodiment 1. For the specific structure, please refer to the description of Embodiment 1. The purpose here is to explain the difference between the two.

[0068] The above-mentioned fixed washboard 31 is fixed on the cylinder body 1 through an adjustment bracket; the adjustment bracket includes a telescopic rod 10, a fixed sleeve 11 and a locking member 9, the fixed sleeve 11 is fixed on the outer wall of the cylinder body 1, and one end of the telescopic rod 10 extends into the fixed sleeve In 11, the other end of the telescopic rod 10 is connected to a fixed washboard, and the telescopic rod 10 and the fixed sleeve 11 are locked by a locking member 9. In the spe...

Embodiment 3

[0072] The substantial difference between the third embodiment and the first embodiment is that a guide tube is also provided.

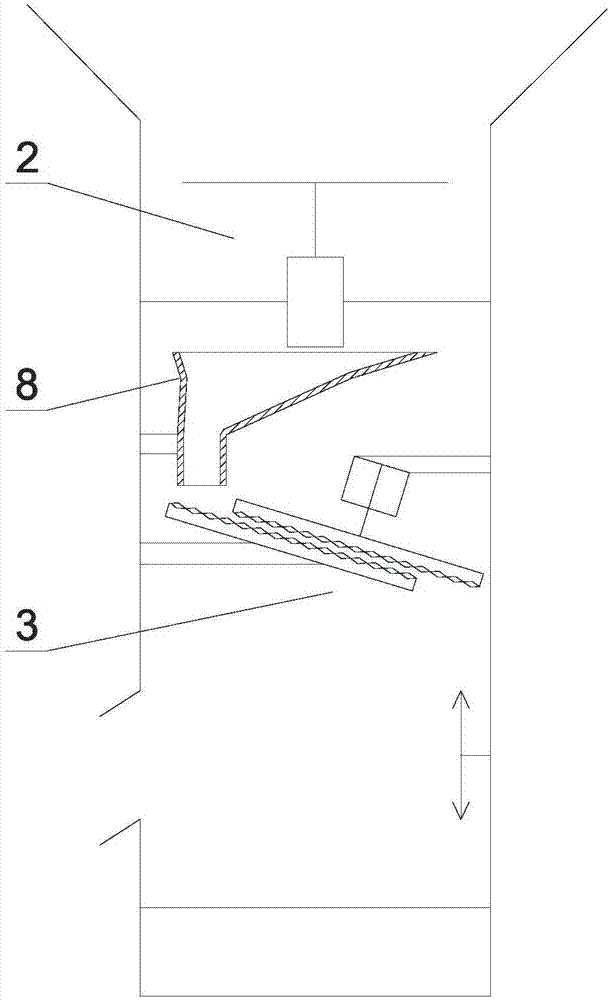

[0073] like image 3 As shown, in the present embodiment, a guide tube 8 is arranged between the above-mentioned shearing device 2 and the peeling device 3, and the guide tube 8 is fixed in the cylinder body by a bracket, and the inlet of the guide tube 8 is connected to the outlet of the shearing device 2, The outlet of guide pipe 8 is connected with the feeding port of peeling device 3 .

[0074] In the specific operation, through the setting of the above-mentioned conduit, the effective guidance of the seeds can be realized, and the seeds output from the shearing device 2 can be smoothly guided to the feeding port position of the peeling device 3, which can effectively prevent the unpeeled seeds from peeling the peeling device. 3 One side leaks, which can effectively improve the peeling rate of seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com