Automatic fish scale removal device

A fish scale, automatic technology, applied in fish cleaning/descaling, fish processing, slaughtering and other directions, can solve problems such as fish surface pollution, reduce processing efficiency, affect processing quality, etc., achieve clean and comprehensive scale removal, and expand the scope of scale removal. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

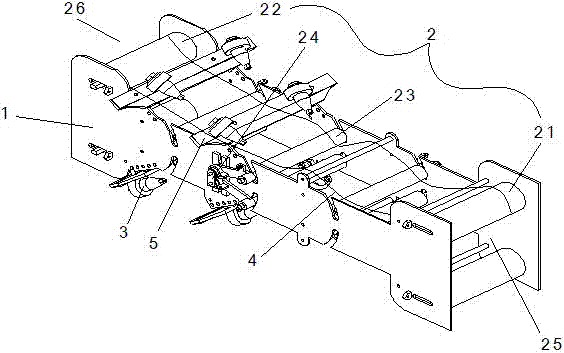

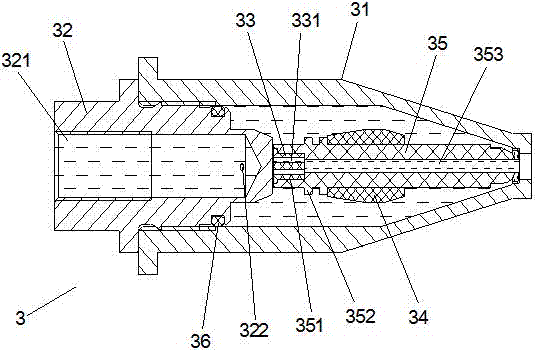

[0019] Such as figure 1 As shown, an automatic descaling device includes a frame 1, and also includes two sets of transmission rollers 2 and several high-pressure spiral nozzles 3. The two sets of transmission rollers 2 are fixed up and down inside the frame 1, and each set of transmission The transmission chain network 4 is fixedly installed on the roller group 1, the area between the transmission chain network 4 is the transportation area, the upper side and the lower side of the frame 1 are fixedly installed with the high-pressure spiral nozzle 3 through the fixing frame 5, and the high-pressure spiral nozzle 3 is located in the fixed position. The left and right ends of frame 5.

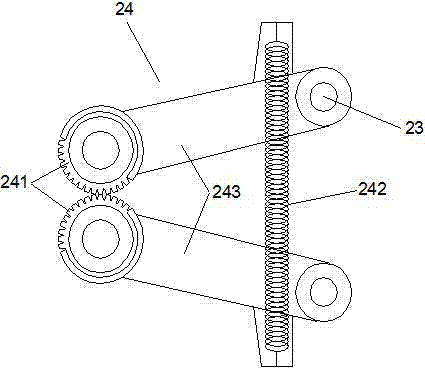

[0020] Such as figure 1 As shown, the parts of each group of driving roller group 2 are arranged symmetrically up and down, and the driving roller group 2 includes driving roller 21, driven roller 22, pressure roller 23 and fan gear control tensioner 24, and one end located at driving roller 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com