Vertebral artery stent and manufacturing method thereof

A production method and technology of vertebral artery, applied in the field of medical devices, can solve the problem of high restenosis rate, achieve the effect of enhancing the ability of controlled release, preventing restenosis, and reducing the amount of drugs used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

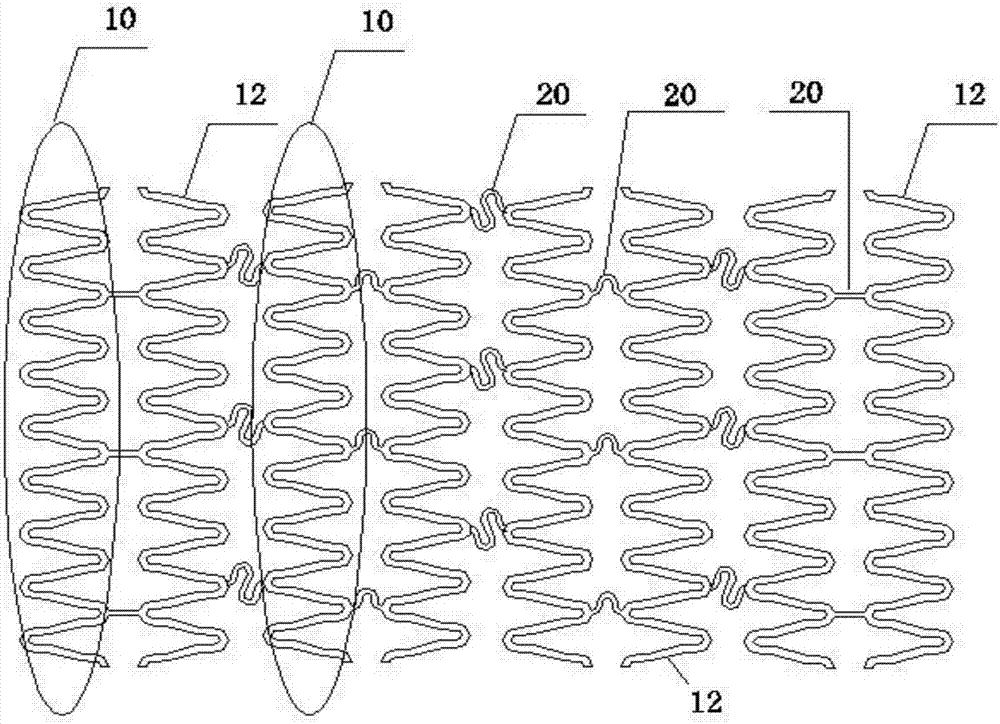

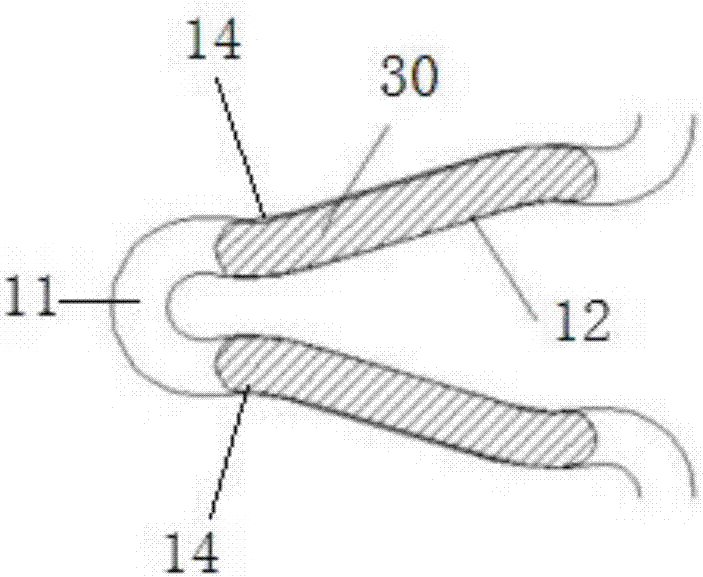

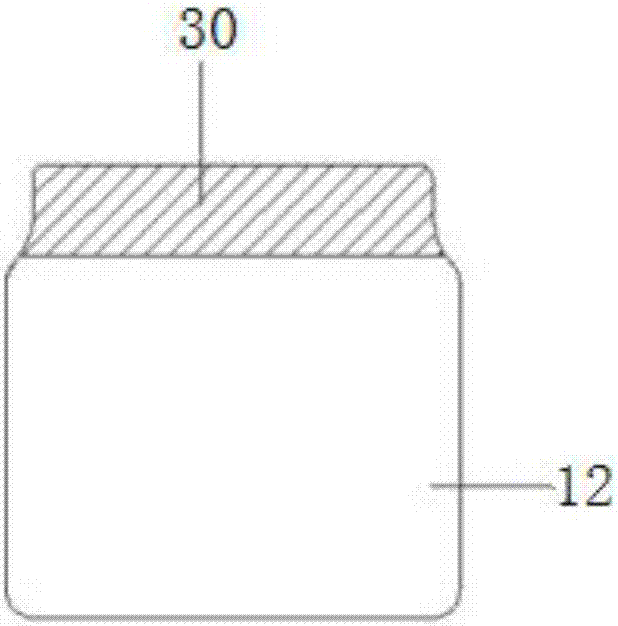

[0049] This embodiment provides a vertebral artery stent, the vertebral artery stent includes a plurality of unit ring structures 10, a plurality of connecting structures 20 and a drug coating 30, wherein: a plurality of the unit ring structures 10 are arranged axially, and a plurality of The connection structure 20 connects a plurality of the unit ring structures 10 to form a columnar structure; the drug coating 30 is only coated on the outer surface of the columnar structure, and the drug coating contains anti-stenosis drug components . Each of the unit ring structures 10 includes a plurality of ring end structures 11 and a plurality of straight rod structures 12, wherein: each of the ring end structures 11 is respectively connected to two of the straight rod structures 12 through two transition structures 14 In between, the two straight rod structures form an approximately "V"-shaped structure, and a plurality of the approximately "V"-shaped structures are arranged along th...

Embodiment 2

[0059] This embodiment provides a method for manufacturing a vertebral artery stent. The method for manufacturing a vertebral artery stent includes: forming a plurality of unit ring structures 10, arranging the plurality of unit ring structures 10 axially, and connecting a plurality of connecting structures 20 The unit ring structure 10 is to form a net column structure; a solution containing anti-stenosis drug components is prepared, and the solution is only coated on the outer surface of the net column structure to form a drug coating.

[0060] Specifically, each unit ring structure 10 is formed by the following method: providing a plurality of ring end structures 11 and a plurality of straight rod structures 12; connecting each ring end structure 11 to two straight rod structures through two transition structures 14 Between the structures 12, so that the two straight rod structures 12 form an approximately "V"-shaped structure, and a plurality of the approximately "V"-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com