Novel efficient amine liquid decoking powder purification device

A purification device and amine liquid technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of affecting the desulfurization effect of dry gas and liquefied gas, the reduction of desulfurization tower tray efficiency, and the filtration effect is not obvious. Achieve the effects of improving desulfurization effect, increasing service life and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

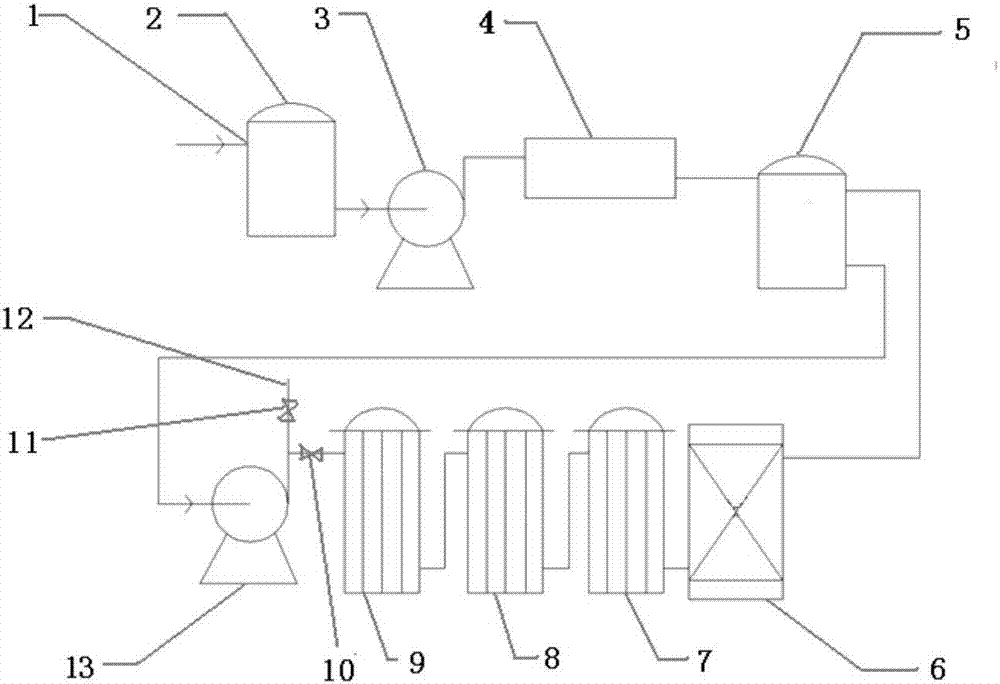

[0019] A new type of high-efficiency amine liquid decoking powder purification device of the present invention will be described in further detail below in conjunction with the accompanying drawings of the description:

[0020] Such as figure 1 As shown, a new high-efficiency amine liquid decoking powder purification device of the present invention includes amine liquid tank B2, machine pump A3, machine pump B13, filter press 4, amine liquid tank A5, heat stable salt adsorber 6, and 5 μm filter 7, activated carbon filter 8, 10μm filter 9, material inlet 1, material outlet 12, valve A10 and valve B11, and the left and right ends of activated carbon filter 8 are connected side by side with 10μm filter 9 and 5μm filter 7, combined to form a set of high-efficiency filtration and separation devices; amine liquid tank A5, pump B13, valve B11, the set of high-efficiency filtration and separation devices formed by combination, and the heat-stable salt adsorber 6 are connected through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com