Steel ingot mould and process for producing fan-shaped electrode

A steel ingot mold and electrode technology, which is applied to the field of steel ingot molds and processes for producing sector-shaped electrodes, can solve the problems of overall deformation of long poured electrodes, difficulty in surface cleaning, and high production efficiency, and achieves guaranteed strength, large casting fillets, and improved filling. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

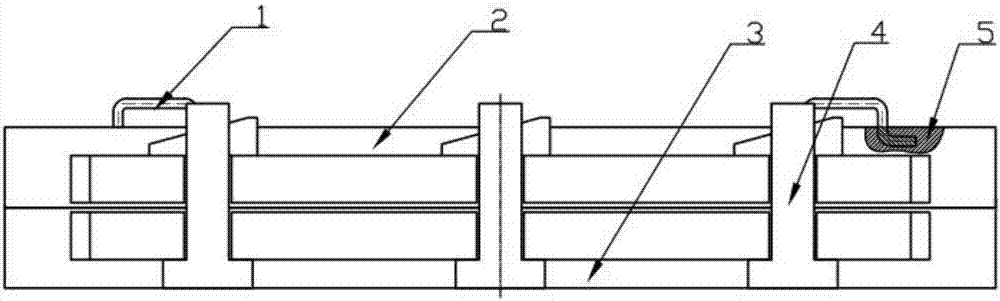

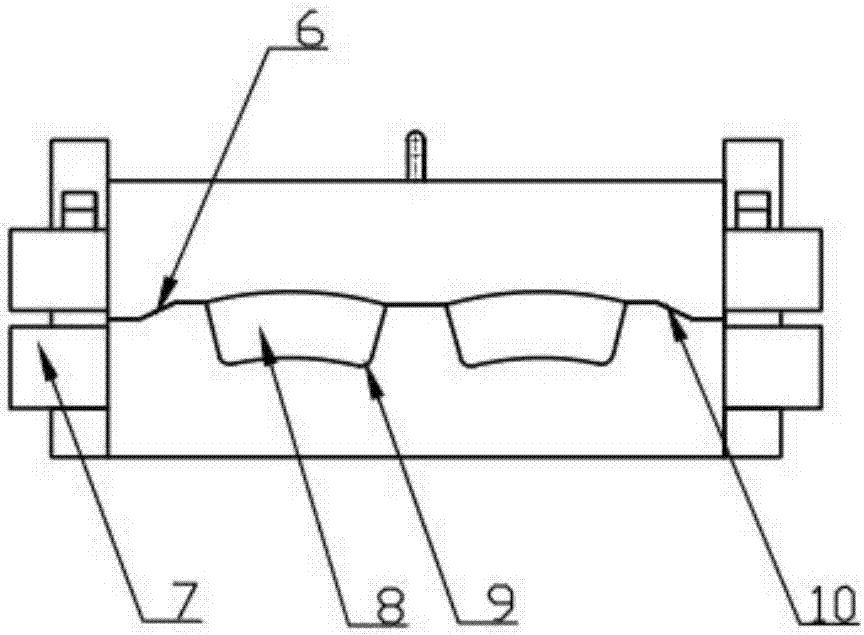

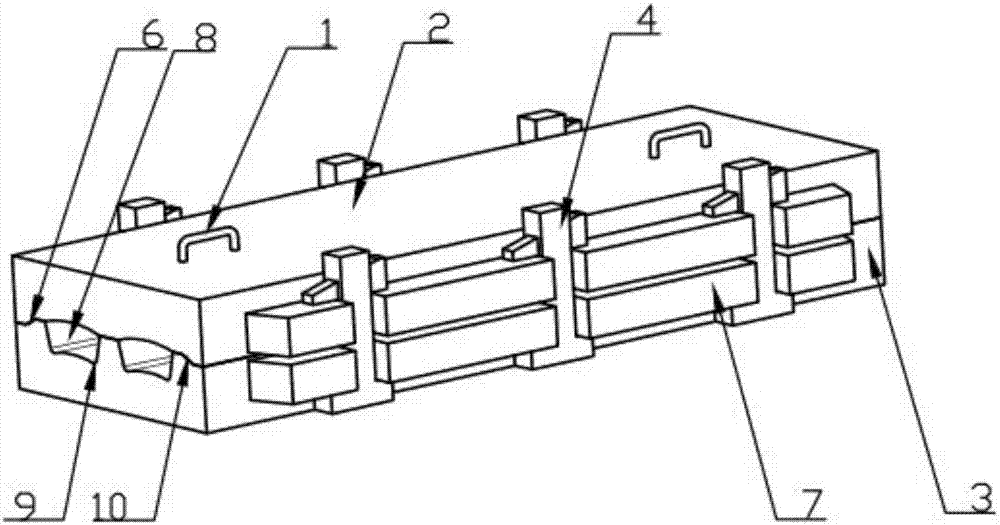

[0036] See attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , the steel ingot mold that the present invention produces fan-shaped electrode comprises upper mold 2, lower mold 3, fixed plate 7, fixed pin 4 and lifting lug 1;

[0037] The lower mold 3 is provided with a cavity 8; the cavity 8 is provided with a casting fillet 9; the lug 1 is fixedly connected to the upper mold 2, and the upper mold 2 and the lower mold 3 are provided with a fixed plate 7. The fixed plate on the upper mold is integrated with the upper mold, the fixed plate on the lower mold is integrated with the lower mold, the upper mold 2 and the lower mold 3 are fixed by the fixed pin 4, the fixed plate of the upper mold 2 and the lower mold 3 There is a gap between the fixed positions, the upper die 2 is provided with an upper die positioning inclination 6, and the lower die 3 is provided with a lower die positioning inclination 10.

[0038] The positioning inclination an...

specific Embodiment 2

[0056] The difference between this embodiment and the first embodiment is that the casting fillet 9 is 5°.

specific Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that the casting fillet 9 is 7°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com