Manufacture method of forecastle deck material of bamboo yacht

A manufacturing method and the technology of the first building, which are applied in the manufacture of tools, ships, and ship construction, can solve problems such as high cost, single product appearance, and difficult recycling, and achieve high cost, broad development prospects, and beautiful and natural appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The concrete steps of a kind of manufacturing method of bamboo yacht forecastle deck material are:

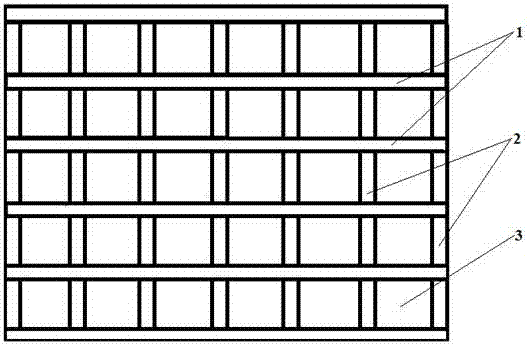

[0024] Step 1: According to the processing method invented by the applicant to produce high-grade yacht materials with black and white interval stripes from moso bamboo (patent authorization number: ZL201110039510.6, the specific process is: first cut the freshly harvested moso bamboo into sections, break and process After being made into bamboo slices, some bamboo slices are put into a wood cooking tank, and superheated steam is passed through for carbonization treatment, so that the bamboo slices are brown; carbonized and non-carbonized bamboo slices are dried and four-sided planed to be processed into standardized bamboo slices. ), and then through the processes of side gluing, aging, interlaced billet formation, and hot pressing (plus side pressing) to make a single-layer bamboo board with black and white interval stripes. The length of the bamboo board is 2.6 meters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com