A control system and method for automatically judging and eliminating coal blockage in raw coal bunkers

An automatic judgment, raw coal bunker technology, applied in transportation and packaging, packaging, loading/unloading, etc., can solve the problems of waste of manpower and material resources, unsatisfactory cleaning effect of compressed air cannon, and low accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

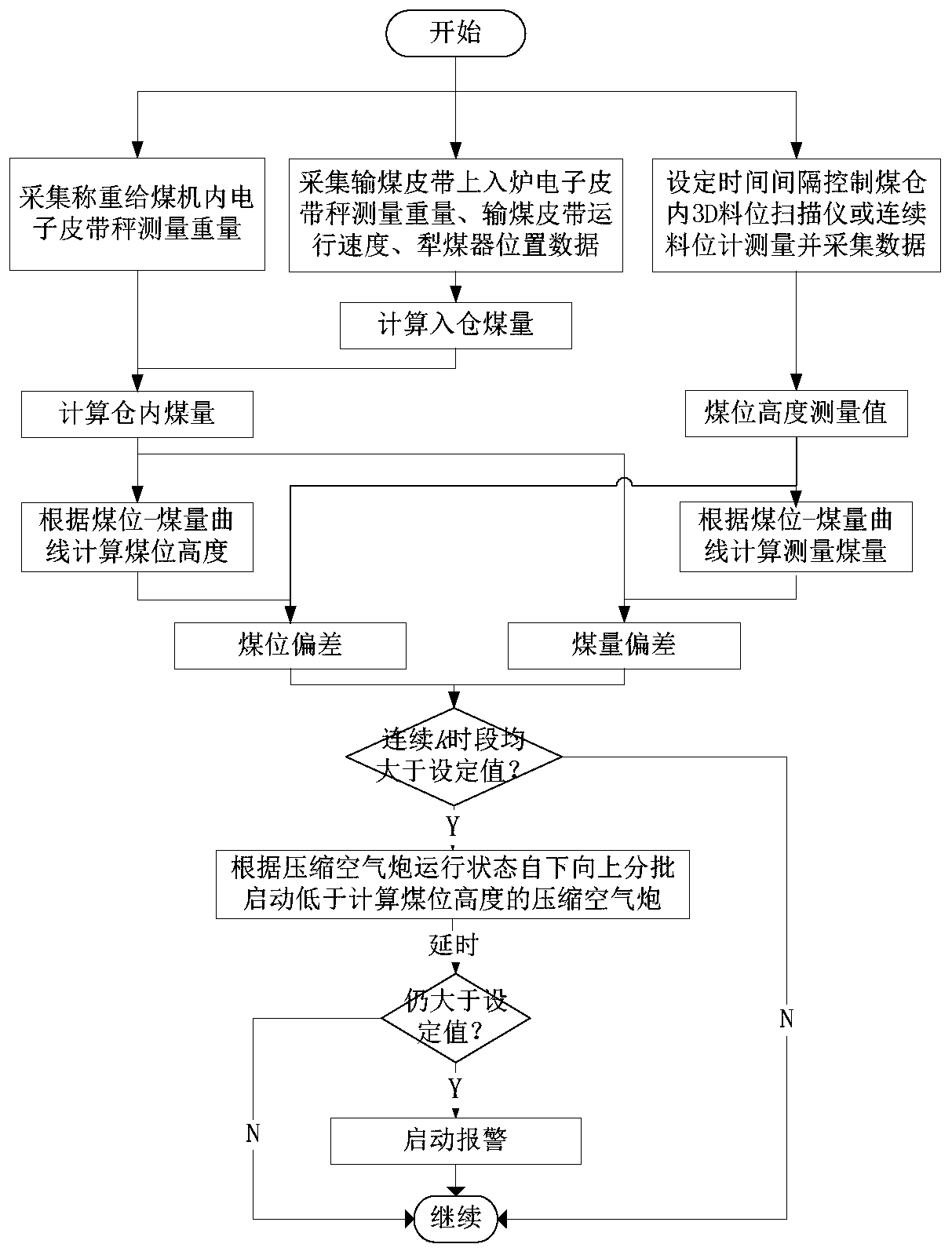

[0032] The present invention aims to provide a control system and method, which can judge the coal blocking situation of the raw coal bunker according to the collected operating data of related equipment and sensor measurement data, and automatically start the compressed air cannon to eliminate the coal blocking when it is judged that the coal blocking occurs. When the coal blockage cannot be eliminated, an automatic alarm function is provided.

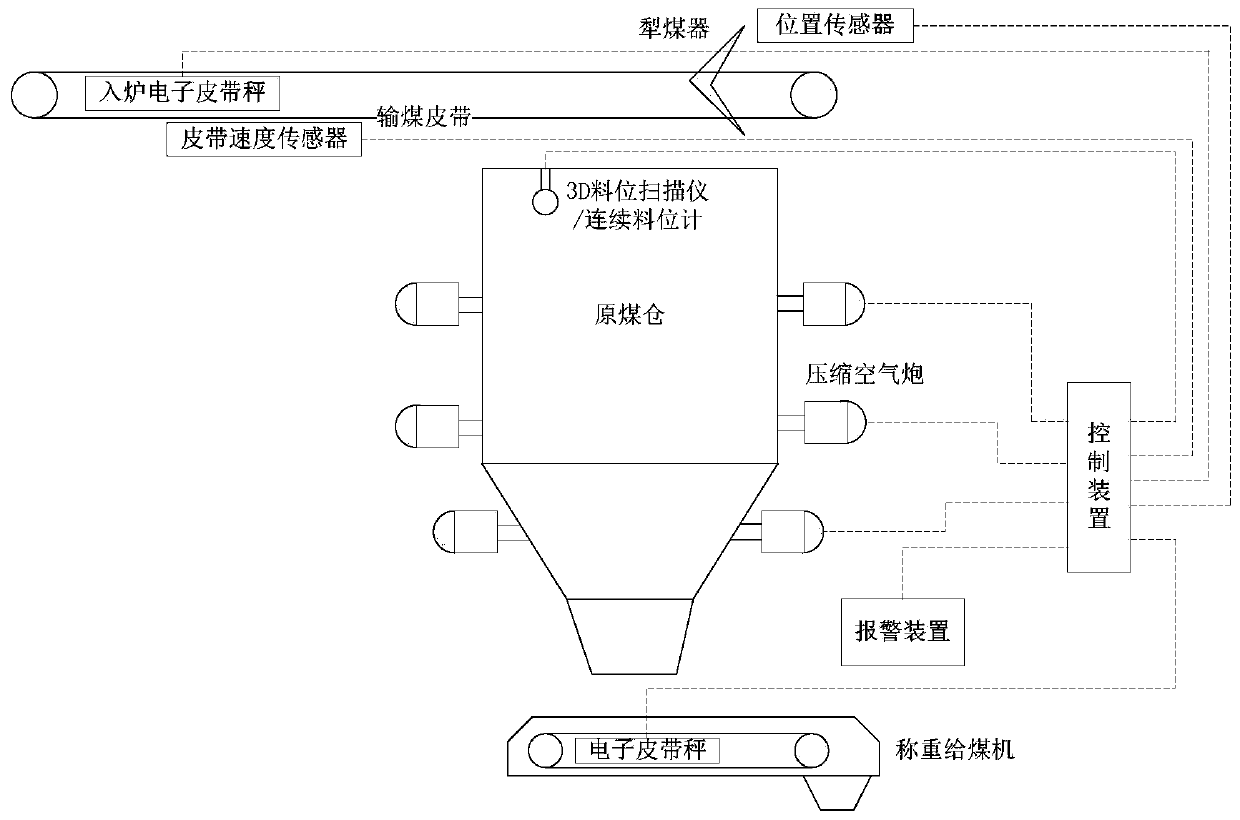

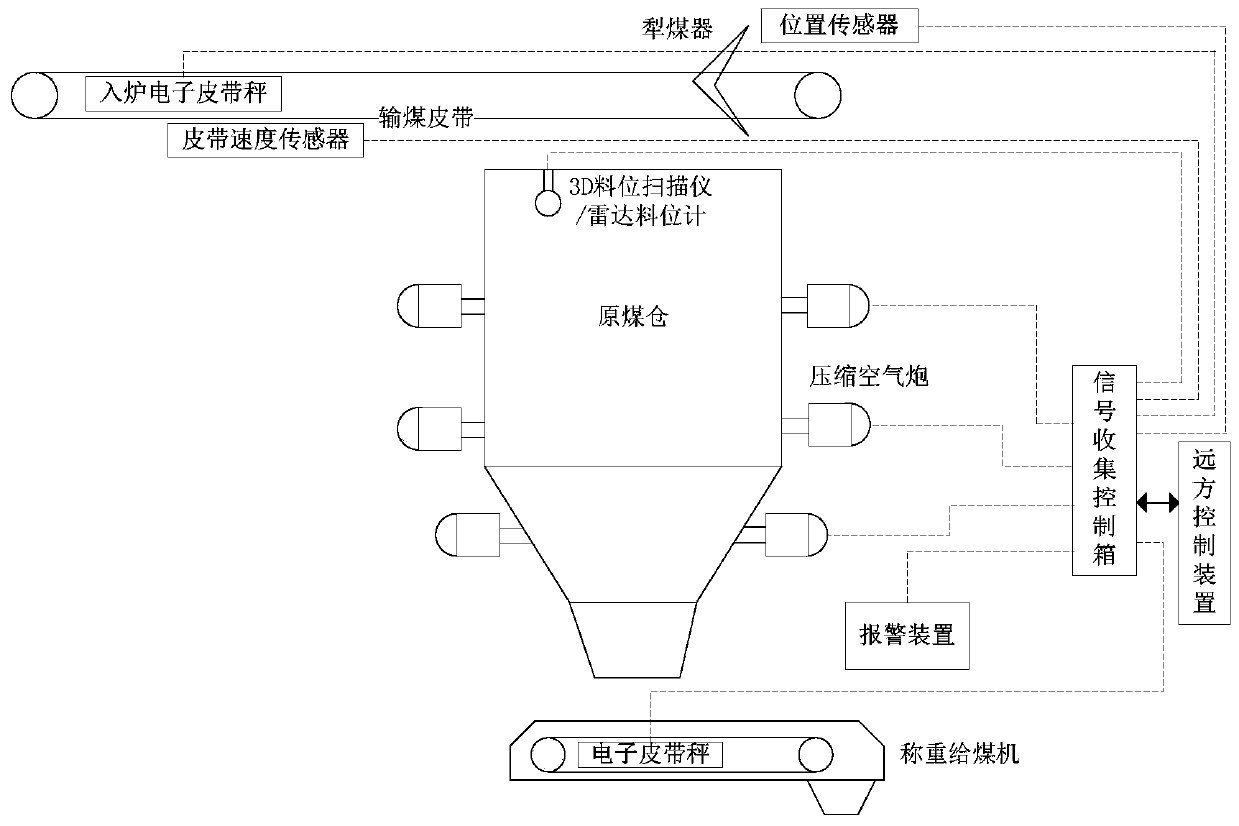

[0033] Attached below figure 1 , 2 The implementation of the control system in the invention will be further described.

[0034] The coal enters the raw coal bunker through the coal conveying belt outside the raw coal bunker and the coal plow. The front or middle part of the coal conveying belt is equipped with an electronic belt scale for entering the furnace. The bottom of the coal conveying belt is equipped with a belt running speed sensor, and the coal plow is equipped with a position sensor. ;The top position of the raw coal bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com