A kind of method that the production solid waste of metformin hydrochloride is recycled

A technology of metformin hydrochloride and solid waste, applied in the direction of organic chemistry and the like, can solve the problems of high pollution, high waste, high consumption, etc., and achieve the effects of avoiding environmental pollution, reducing pollution and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

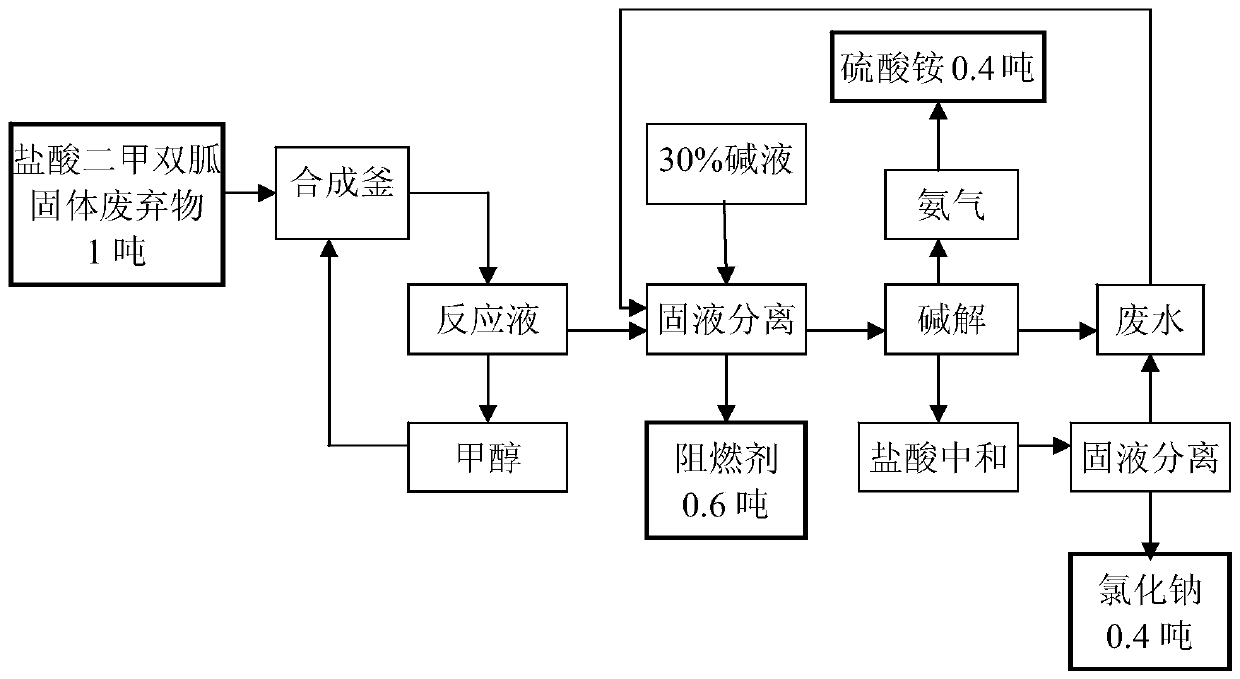

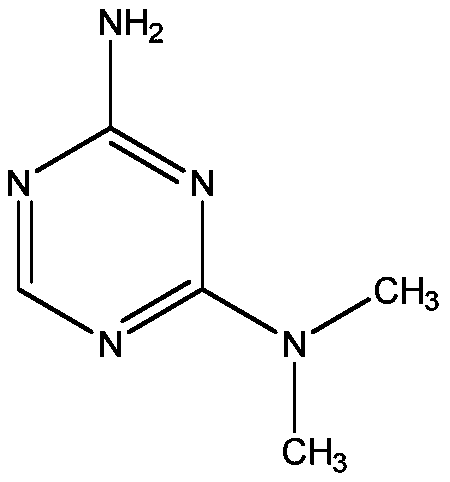

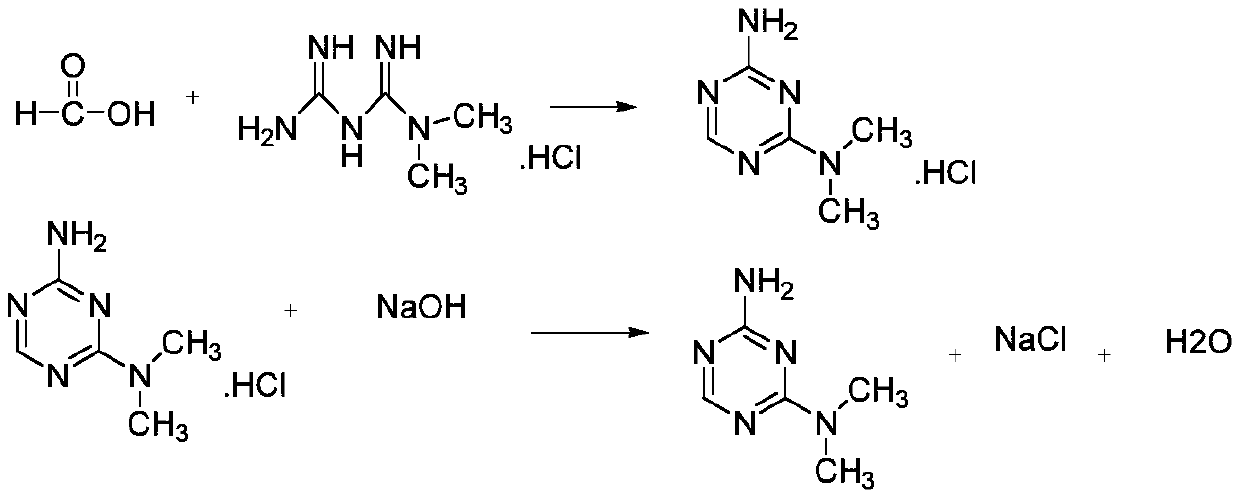

[0022] Weigh 100 g of metformin hydrochloride solid waste, which contains 25 g (0.15 mol) of metformin hydrochloride, 65 g of melamine derivatives, 8 g of water, and 2 g of other salts. Join H 2 O 500g and formic acid 8.28g (0.18mol). Warm up to reflux and react for 5h. After the reaction, cool down to 30°C, add dropwise 72.0g of 30% lye, adjust the pH to 8-10, a large amount of precipitates are formed, stir at 25-35°C for 2 hours, and filter with suction to obtain 90.0g of white solids of melamine derivatives. The solid was placed in a blast oven at 60°C, dried for 12 hours, and weighed to obtain 81.5 g (0.586 mol) of a dry product.

Embodiment 2

[0024] Weigh 200 g of metformin hydrochloride solid waste, which contains 50 g (0.3 mol) of metformin hydrochloride, 130 g of melamine derivatives, 16 g of water, and 4 g of other salts. Join H 2 O 1000 g and formic acid 16.56 g (0.36 mol). Warm up to reflux and react for 5h. After the reaction was completed, the temperature was lowered to 30°C, 145g of 30% lye was added dropwise, the pH was adjusted to 8-10, a large amount of precipitate was formed, stirred at 25-35°C for 2h, and suction filtered to obtain 182g of white solid of melamine derivative. The solid was placed in a blast oven at 60°C, dried for 12 hours, and weighed to obtain 164 g (1.180 mol) of a dry product.

Embodiment 3

[0026] Weigh 100 g of metformin hydrochloride solid waste, which contains 25 g (0.15 mol) of metformin hydrochloride, 65 g of melamine derivatives, 8 g of water, and 2 g of other salts. Join H 2 O 500g and formic acid 9.20g (0.2mol). Warm up to reflux and react for 5h. After the reaction, cool down to 30°C, add 75.0g of 30% lye dropwise, adjust the pH to 8-10, a large amount of precipitates are formed, stir at 25-35°C for 2 hours, and filter with suction to obtain 89.5g of white solid of melamine derivative. The solid was placed in a blast oven at 60°C, dried for 12 hours, and weighed to obtain 81 g (0.583 mol) of a dry product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com