A kind of PC alloy material and preparation method thereof

A technology of alloy materials and structural units, applied in the field of high-performance PC alloy materials and their preparation, can solve the problems of insufficient use of the superior properties of inorganic materials, easy water absorption and wear resistance, notch sensitivity, etc., and achieve insulation and thermoelectric stability. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] Provide the preparation method of high-strength PC alloy material of the present invention below, specifically comprise the following steps:

[0072] (1), prepare each raw material according to above-mentioned composition;

[0073] (2), according to the above-mentioned weight ratio, take the dried aluminum-coated modified magnesium oxide powder, surface-modified alumina powder and rutile titanium dioxide, and after fully mixing and uniformly, the powder mixture is obtained;

[0074](3), weigh the PC resin of the above weight portion, and add it into the high-speed mixer together with the powder mixture obtained in step (2), and add the modified compound weighed according to the weight ratio together. Graphene, composite flame retardant, composite toughening agent, compatibilizer, silane coupling agent, antioxidant, anti-dripping agent and ultraviolet light absorber, so that all substances are stirred together for 120 to 160 minutes for premixing Finally, each material ...

Embodiment 1

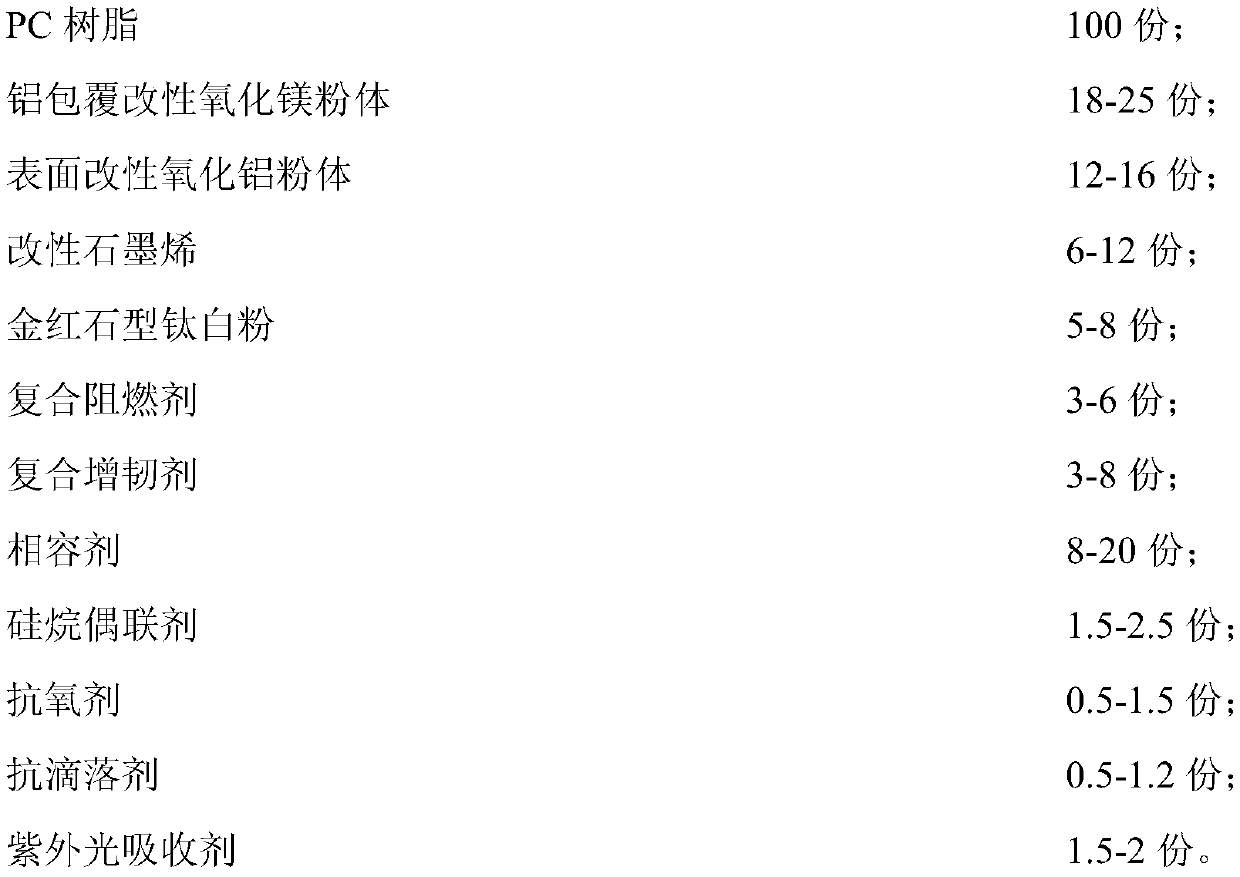

[0077] Weigh each substance according to the following parts by weight and mix according to the above method to obtain the PC alloy material, wherein

[0078]

[0079] Wherein more than 90 mol% of the PC resin is the above-mentioned structural units (I) and (II), and the content ratio of the structural unit (II) is 65 mol% relative to the total amount of the structural unit (I) and the structural unit (II).

[0080] Wherein, more than 90% of the magnesium oxide powder in the aluminum-coated modified magnesium oxide powder has a particle size of 25-35 microns, and the thickness of the aluminum coating layer is between 1-5 nm.

[0081] The surface-modified alumina powder is alumina powder whose surface is modified by silane, and the particle diameter of more than 90% of the alumina powder is between 60-80nm.

[0082] The modified graphene is silanized modified graphene, and the number of graphene layers is between 1 and 30 layers.

[0083] The particle size of rutile titaniu...

Embodiment 2

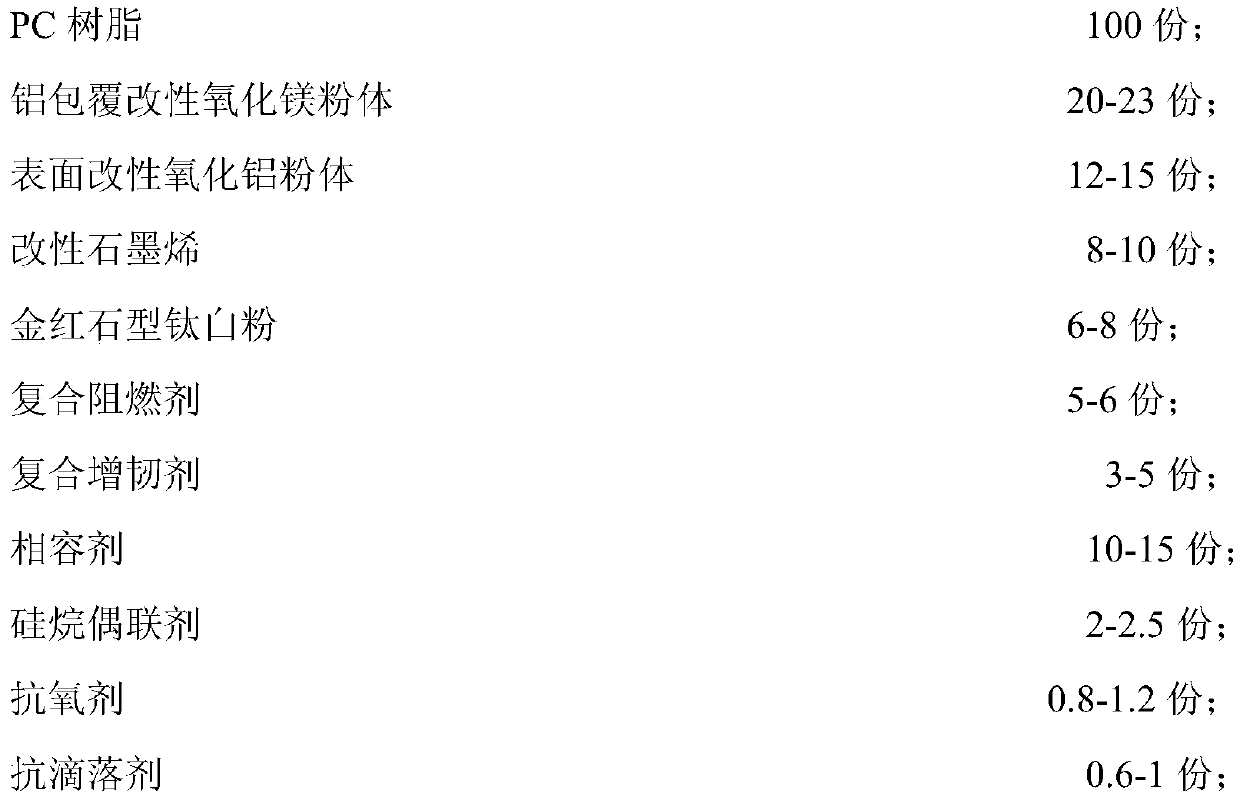

[0088] Weigh each substance according to the following parts by weight and mix according to the above method to obtain the PC alloy material, wherein

[0089]

[0090] Wherein more than 90 mol% of the PC resin is the above-mentioned structural units (I) and (II), and the content ratio of the structural unit (II) is 75 mol% relative to the total amount of the structural unit (I) and the structural unit (II).

[0091] Wherein, more than 90% of the magnesium oxide powder in the aluminum-coated modified magnesium oxide powder has a particle size of 25-35 microns, and the thickness of the aluminum coating layer is between 3-8 nm.

[0092] The surface-modified alumina powder is alumina powder coated with ammonium pyrrolidine dithiocarbamate on the surface, and more than 90% of the alumina powder has a particle size between 60-80nm.

[0093] Wherein the modified graphene is silanized modified graphene, and the number of graphene layers is between 1-15 layers.

[0094] The particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com