Transparent nylon elastomer and preparation method thereof

A nylon elastomer and nylon technology, applied in the field of nylon elastomers, can solve the problems of complicated production raw materials and production process, low flexibility of transparent nylon, difficult production and preparation, etc., and achieve stable product performance, simple production process, and low equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

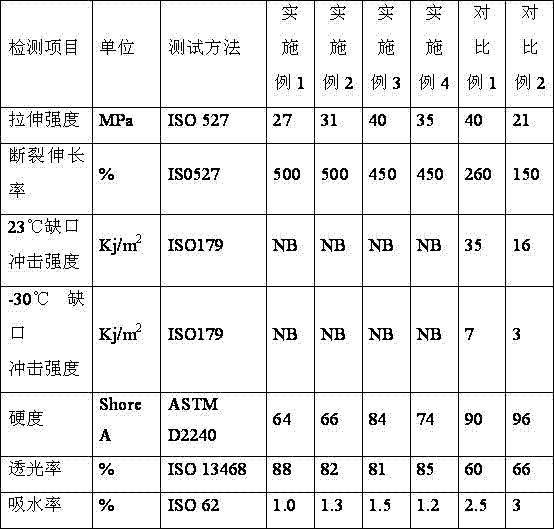

[0032] Embodiment 1~4: a kind of transparent nylon elastomer, described transparent nylon elastomer is made up of following weight parts, as shown in table 1:

[0033] Table 1

[0034] Component Example 1 Example 2 Example 3 Example 4 Nylon 30~85 parts 50 copies 40 copies 68 copies 42 copies Polystyrene-b-poly(ethylene / ethylene / propylene)-b-polystyrene block copolymer 8-50 parts 20 copies 25 copies 14 copies 30 copies 10-20 parts of N,N-dimethyl-p-toluenesulfonamide 1 copy 2 copies 1 copy 15 copies 15-25 parts of paraffin oil 13 copies 19 copies 1 copy 2 copies 5-25 parts of naphthenic oil 5 copies 1 copy 8 servings 1 copy Maleic anhydride grafted SEBS / SEEPS1~15 parts 8 servings 10 copies 6 servings 5 copies Antioxidant 1098 is 0.1 to 2 parts 1.2 parts 1.3 parts 0.5 parts 1.6 servings Lubricant 0.1~2 parts 0.3 parts 0.7 parts 0.5 parts 0.6 parts 0.1-2 par...

Embodiment 1

[0036] In Example 1, the nylon is polylaurolactam, referred to as PA12 (relative viscosity is 3), the lubricant is lubricant EB-FF, the light stabilizer is light stabilizer UV234, and the nucleating agent is P22 of Niu Nuo Chemical;

Embodiment 2

[0037] In Example 2, the nylon is nylon 6 (relative viscosity 3.2), the lubricant is lubricant EB-FF, the light stabilizer is light stabilizer UV234, and the nucleating agent is P22 of Niu Nuo Chemical;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com