Special environmental-friendly glutinous rice glue powder for rooms for children and processing method thereof

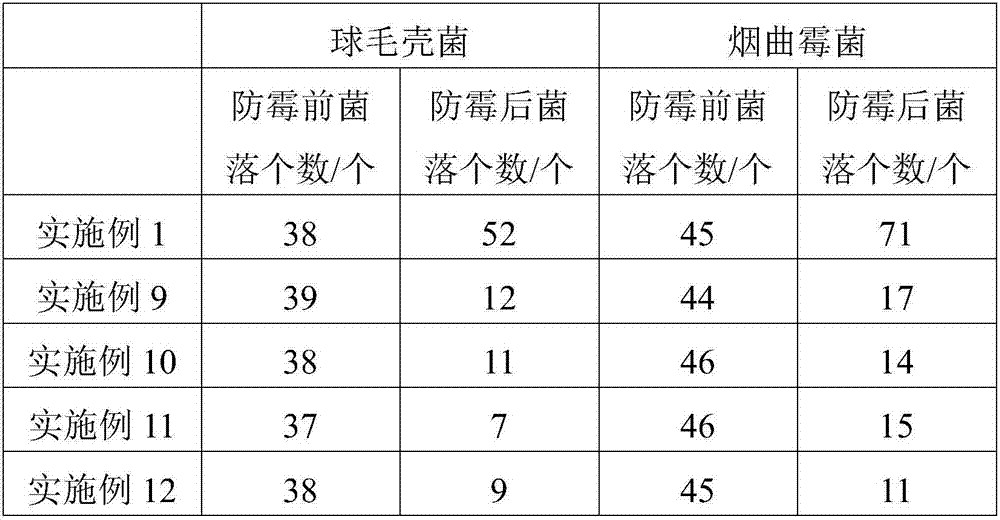

A processing method and technology for children's rooms, applied in the field of glutinous rice glue, can solve the problems of poor anti-mold and sterilization effects, weak cohesiveness, and short service life, and achieve improved service life, improved cohesion, and excellent anti-mold and anti-mold effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The processing method of special environment-friendly glutinous rice glue powder for children's rooms comprises the following steps:

[0059] (1) Steaming: add 20 parts by weight of water to 100 parts by weight of glutinous rice, spread it flat to a thickness of 2 cm, and steam for 20 minutes with steam;

[0060](2) Primary drying: the steamed glutinous rice is dried for 3 hours at a temperature of 20° C., a relative air humidity of 30%, and an air flow rate of 2 m / s;

[0061] (3) tableting: the dried glutinous rice is pressed into a glutinous rice cake with a thickness of 1 cm;

[0062] (4) Secondary drying: the glutinous rice cake is dried for 2 hours at a temperature of 1°C, a relative air humidity of 30%, and an air flow rate of 2 m / s, and the glutinous rice cake is cut into 1cm×1cm×1cm squares to obtain glutinous rice glue pink;

[0063] (5) Sealed packaging: the glutinous rice glue powder is sealed and packaged. The environmental-friendly glutinous rice gum pow...

Embodiment 2

[0065] The processing method of the special environmentally friendly glutinous rice glue powder for children's room includes the following steps:

[0066] (1) steaming: in the glutinous rice of 100 parts by weight, add the water of 20 parts by weight, lay flat into 2cm thick, then steam with water vapor for 20min;

[0067] (2) high-pressure treatment: the glutinous rice after the steaming is allowed to stand for 3min at 200MPa and a temperature of 70°C;

[0068] (3) Primary drying: drying the glutinous rice after the high pressure treatment for 3h at a temperature of 20° C., a relative air humidity of 30%, and an air flow rate of 2 m / s;

[0069] (4) tabletting: the dried glutinous rice is pressed into a glutinous rice cake with a thickness of 1 cm;

[0070] (5) Secondary drying: the glutinous rice cake is dried for 2 hours at a temperature of 1° C., a relative air humidity of 30%, and an air flow rate of 2 m / s, and the glutinous rice cake is cut into 1cm×1cm×1cm squares to ob...

Embodiment 3

[0073] It is basically the same as Example 2, except that the pressure of the high-pressure treatment in the step (2) is 300 MPa. The environmental-friendly glutinous rice gum powder for children's room of Example 3 was obtained.

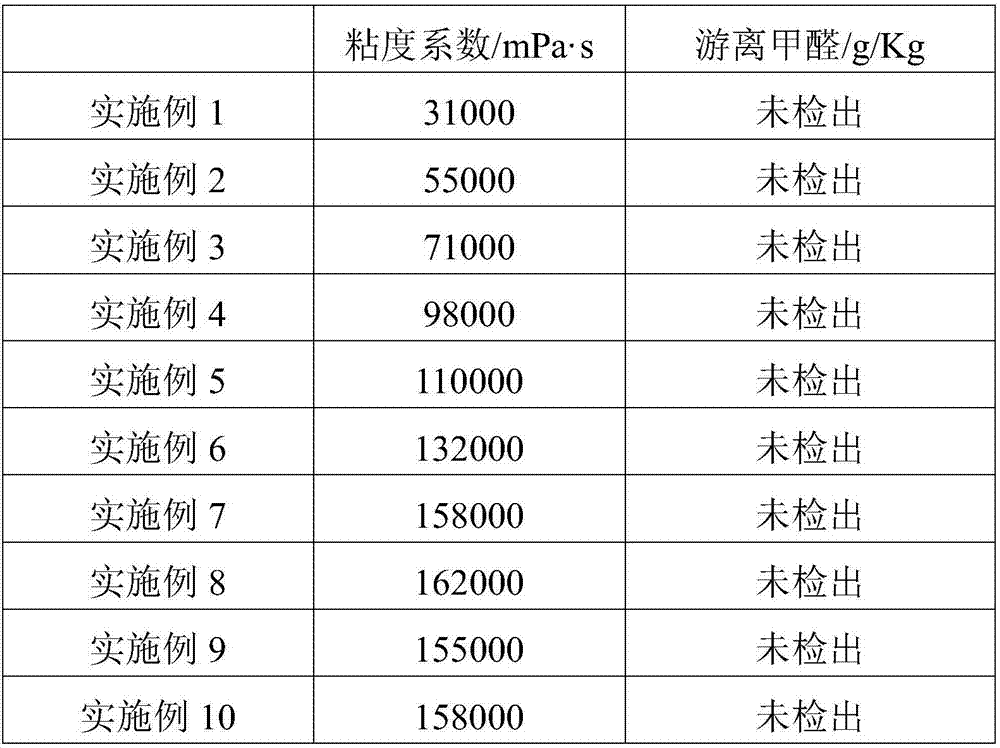

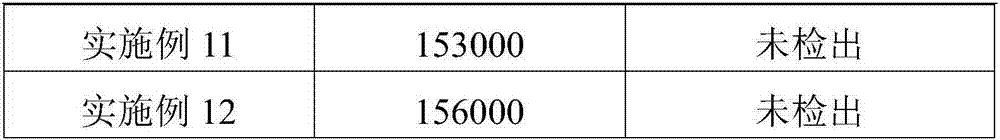

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com