Preparation method of PAA (polyacrylic acid) hydrogel adhesive

A hydrogel adhesive and polypropylene technology, applied in the direction of adhesive additives, acidic copolymer adhesives, adhesive types, etc., can solve the problems of toxic natural environment, ecological system damage, etc., and achieve broad research and development value, Easy-to-control, simple-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

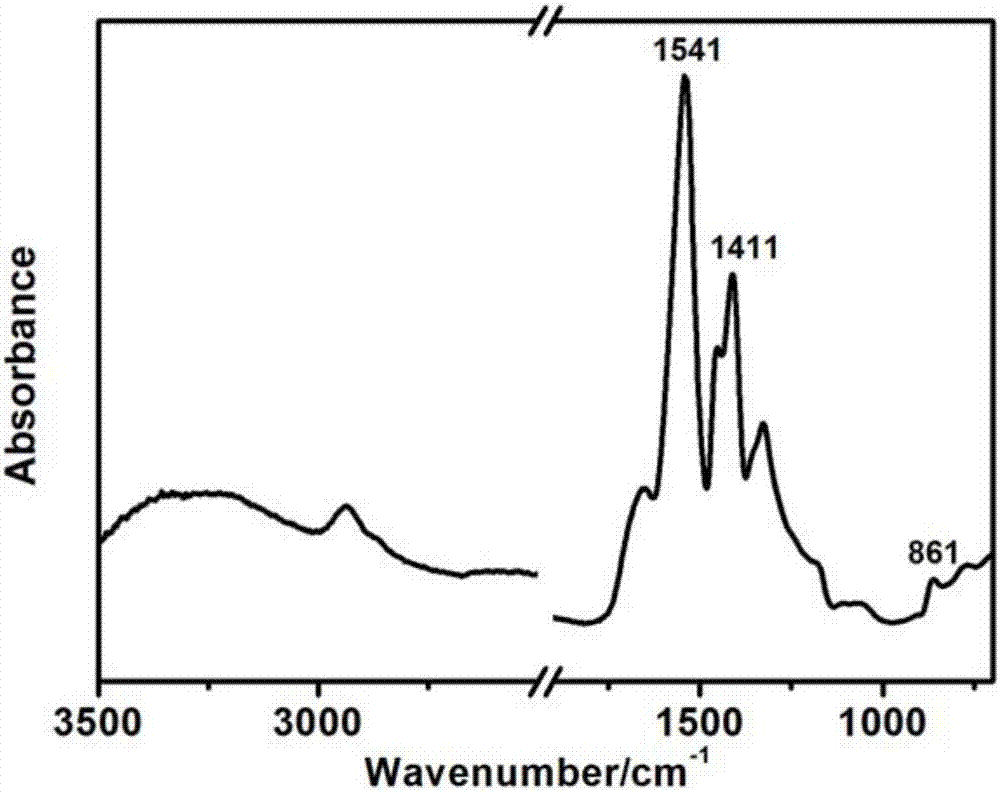

[0023] Prepare 0.2mol / L PAA (Mw=250 000), 0.1mol / L CaCl 2 20mL of the mixed aqueous solution, under vigorous stirring, 10mL 0.1mol / L Na 2 CO 3 The solution was added dropwise into the mixed solution at a rate of 1mL / min, accompanied by Na 2 CO 3 With the addition of the solution, polyacrylic acid hydrogel is gradually formed around the magnetic stirring bar. After obtaining the gel, after repeated washing, a pure polyacrylic acid gel is obtained, and the infrared spectrum is as follows: figure 1 .

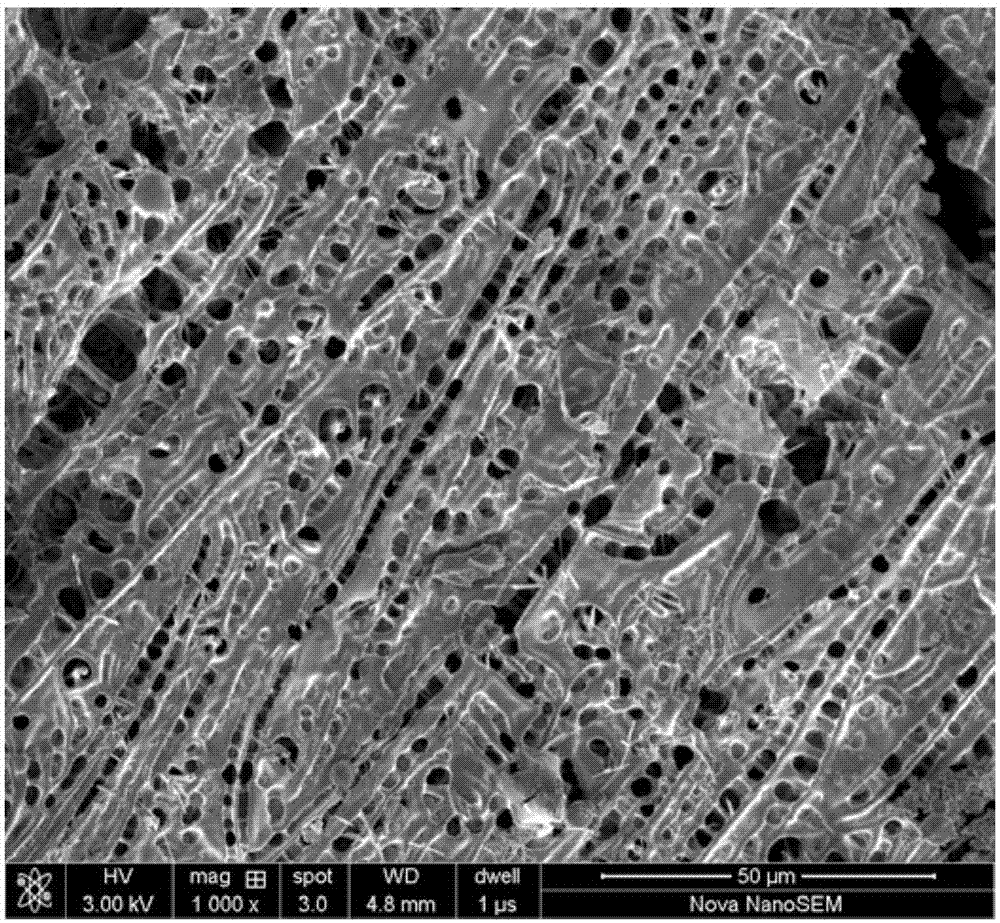

[0024] After the product is prepared, it is freeze-dried to obtain a dry polyacrylic acid hydrogel, which is analyzed by a scanning electron microscope, as shown in the attached figure 2 shown. The obtained gel film was dried at room temperature, and the obtained gel film was as attached image 3 shown.

Embodiment 2

[0026] Prepare 0.2mol / L PAA (Mw=100 000), 0.1mol / L CaCl 2 20mL of the mixed aqueous solution, under vigorous stirring, 10mL 0.1mol / L Na 2 CO 3 The solution was added dropwise into the mixed solution at a rate of 1mL / min, accompanied by Na 2 CO 3 With the addition of the solution, polyacrylic acid hydrogel is gradually formed around the magnetic stirring bar. After obtaining the gel, after repeated washing, a pure polyacrylic acid gel is obtained.

Embodiment 3

[0028] Prepare 0.1mol / L PAA (Mw=250 000), 0.1mol / L CaCl 2 20mL of the mixed aqueous solution, under vigorous stirring, 10mL 0.1mol / L Na 2 CO 3 The solution was added dropwise into the mixed solution at a rate of 1mL / min, accompanied by Na 2 CO 3 With the addition of the solution, polyacrylic acid hydrogel is gradually formed around the magnetic stirring bar. After obtaining the gel, after repeated washing, a pure polyacrylic acid gel is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com