Axial piston variable pump with four oil ports and low-noise parallel distribution structure

A four-port, low-noise technology, applied in the field of low-noise parallel-distribution structure four-port axial piston variable pump, can solve the problems that the axial piston pump cannot rotate in both directions and the working noise is high, and achieves high reliability. , long life, high stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

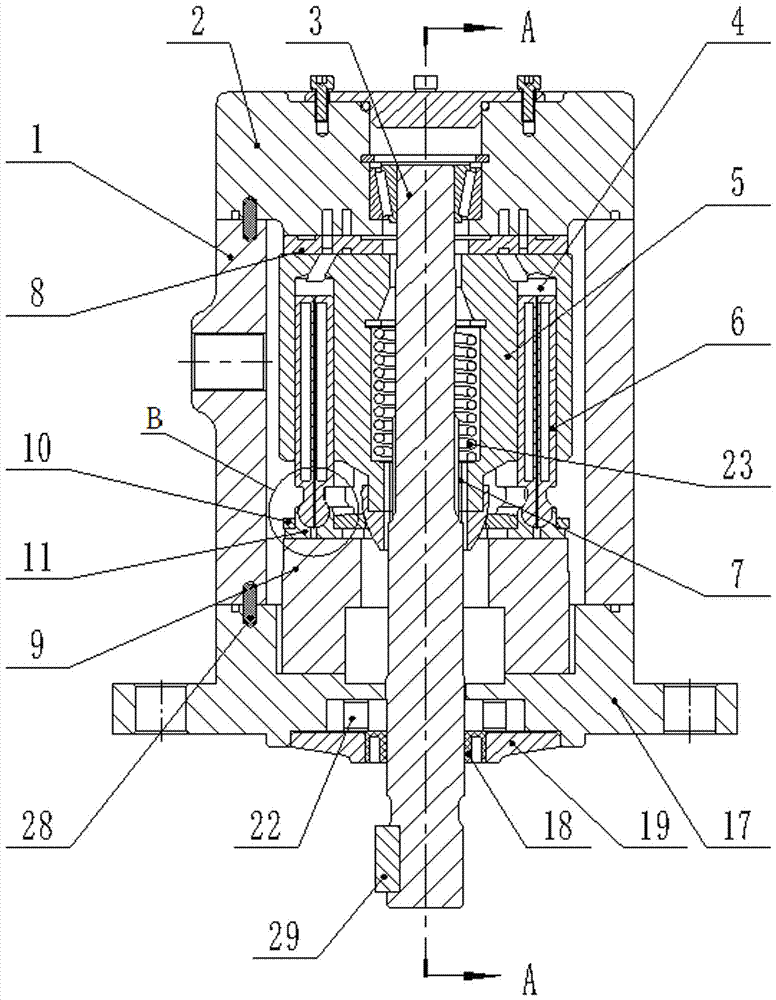

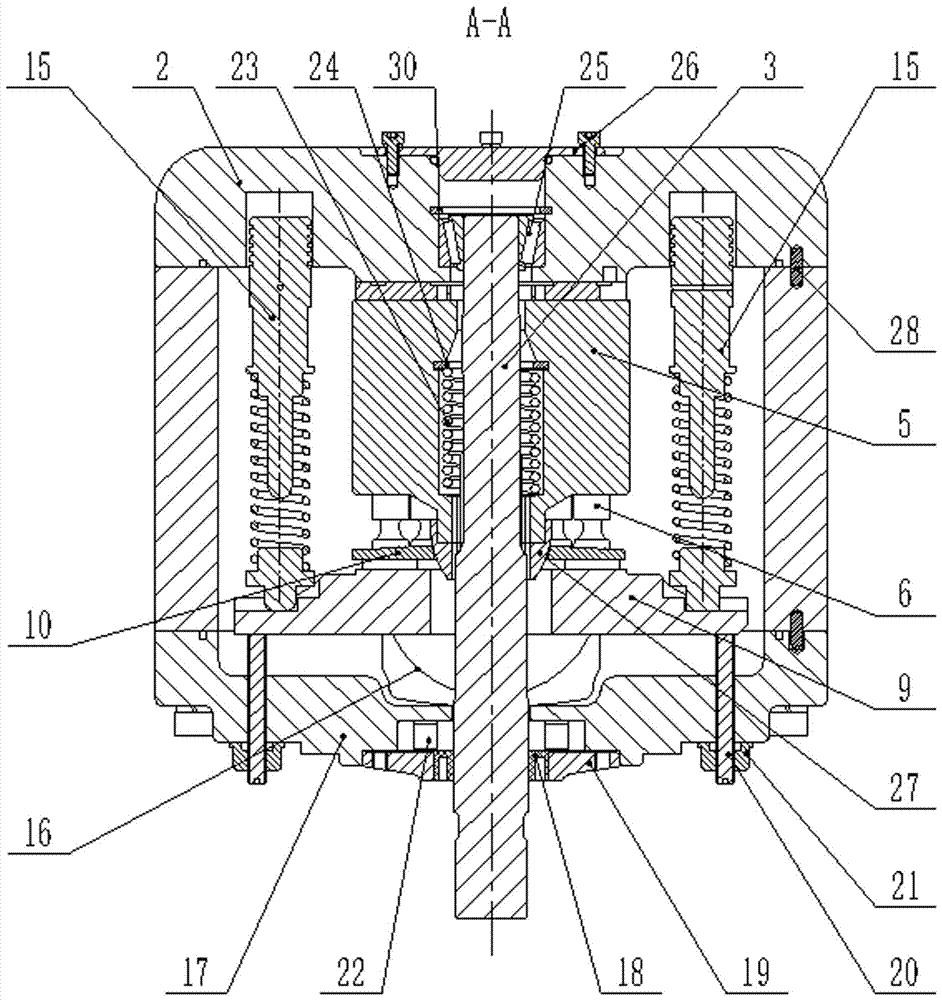

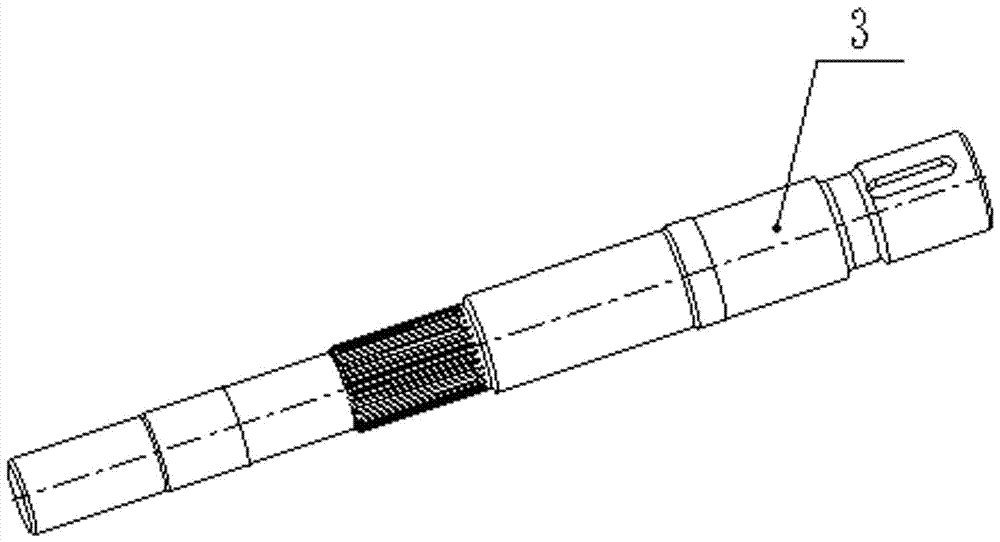

[0046] A low-noise parallel flow distribution structure four-port axial plunger variable pump, including a casing, a pump front cover, a pump rear cover, a main shaft, a swash plate cradle, a return plate, a cylinder block, a flow distribution plate, a plunger, and a sliding shoe , bearings, displacement control mechanism and other components, the cylinder of the pump has ten plunger holes, the plunger is matched with the cylinder plunger hole; the cylinder flow distribution hole is divided into two groups, five in each group, located in different branches On the degree circle; there is a spline hole in the center of the cylinder body, and the main shaft passes through the cylinder body to cooperate with the spline hole; the axis of the plunger hole on the cylinder body is parallel to the axis of the main shaft; the flow distribution plate adopts the structure of inner and outer ring flow distribution windows, The oil suction and discharge distribution window is symmetrical to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com