Pilot-operated type steam hydrophobic valve

A steam trap and pilot-operated technology, applied in the direction of steam traps, mechanical equipment, etc., can solve the problems of increased steam leakage, easy wear of ball valves, and low working pressure, so as to reduce the number of times, prolong the service life, and improve the load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

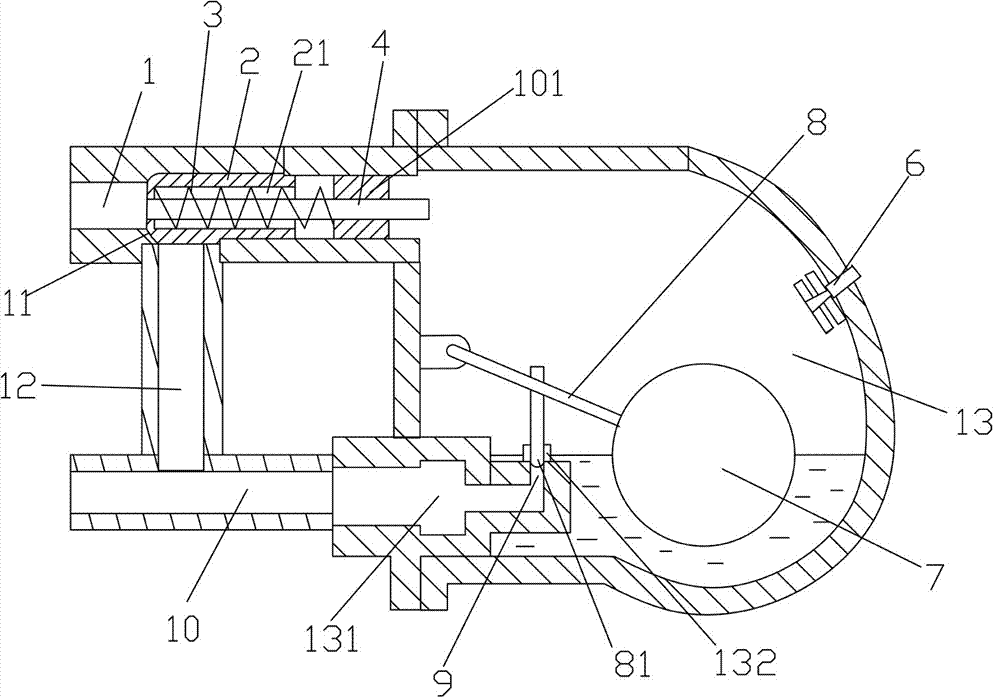

[0040]A pilot-operated steam trap, comprising a valve body with a main valve cavity 13, a floating ball 7 is arranged in the main valve cavity, and inlet valves communicated with the main valve cavity are respectively provided on the upper and lower parts of the valve body. The air port 1 and the liquid discharge port 10, the liquid discharge channel 12 is also communicated between the air inlet port and the liquid discharge port, and the upper and middle wall of the main valve chamber is also provided with an openable air outlet hole, so The air inlet is provided with a main valve core 2 for opening and closing the liquid discharge channel and having a throttling tube 4 coaxially arranged with the air inlet for ventilation, and the throttling tube runs through the main The spool communicates with the inside and outside of the main spool.

[0041] The inner end connected to the main valve chamber on the air inlet is provided with a limit ring 101, the throttle tube passes thro...

Embodiment 2

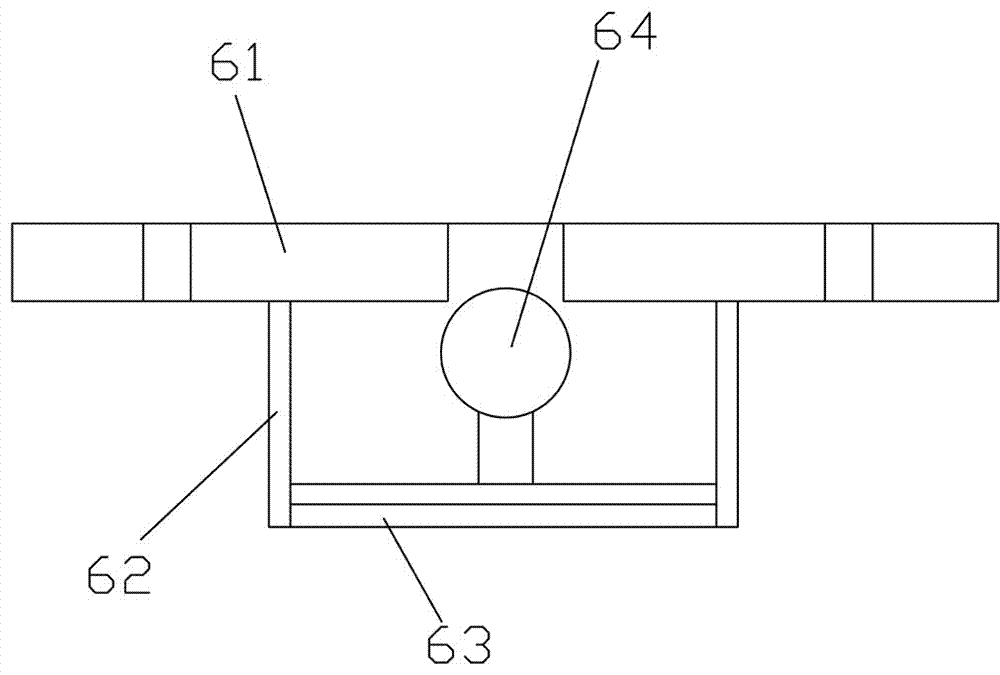

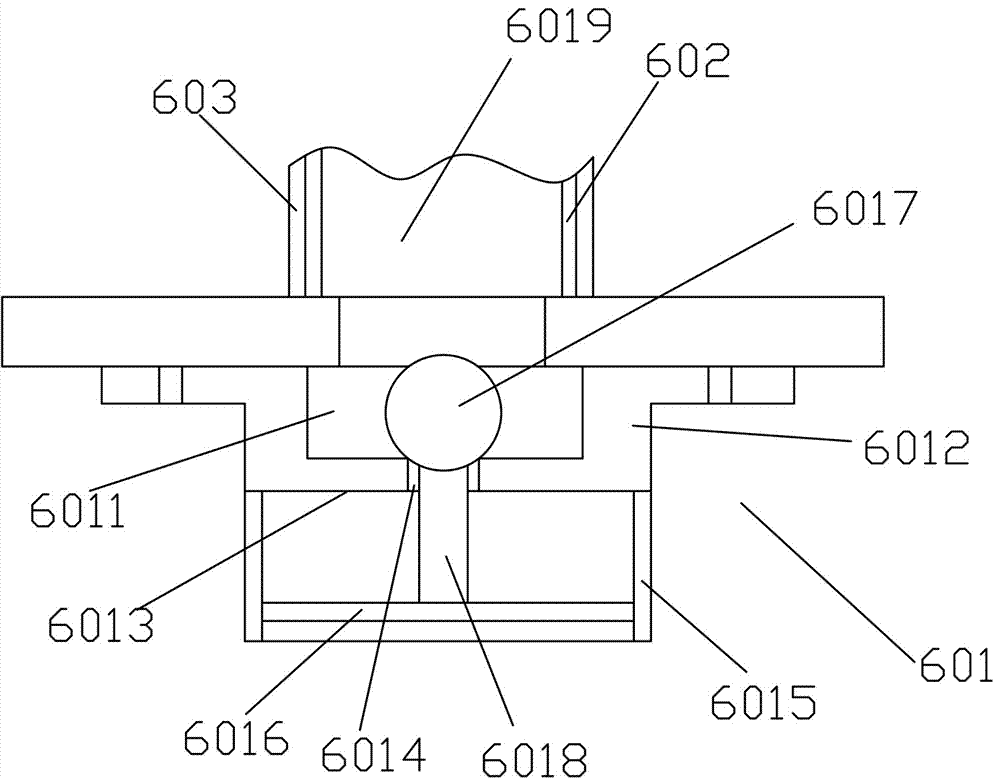

[0046] The difference from the above embodiment is that the air outlet is provided with an emptying valve 6, and the emptying valve is a bimetal valve. The bimetal valve includes a flange 61 fixed on the air outlet with a through hole corresponding to the air outlet, a support frame 62 fixed on the flange and located in the main valve cavity, fixed on the support The two stacked metal sheets 63 on the frame are fixed on the metal sheet and set corresponding to the through holes on the flange, and can open or block the through holes according to the thermal expansion and contraction of the metal sheets. 64.

[0047] The design of the bimetal sheet is to drive the valve plug to work through the deformation of two metal sheets with different expansion coefficients when the temperature changes.

[0048] The air outlet is arranged on the side of the main valve chamber wall opposite to the air inlet, and the air inlet and liquid outlet are located on the same side of the main valve...

Embodiment 3

[0050] The difference from the above embodiments is that the top of the main valve chamber is provided with a manual emptying valve 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com