Boiler heating systems and boiler heating main systems

A heating system and boiler technology, applied in the field of boilers, can solve the problems of reduced fuel utilization rate, low additional heat recovery rate, and high energy consumption of the boiler system, and achieve the effects of reducing energy consumption, improving energy conservation and economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

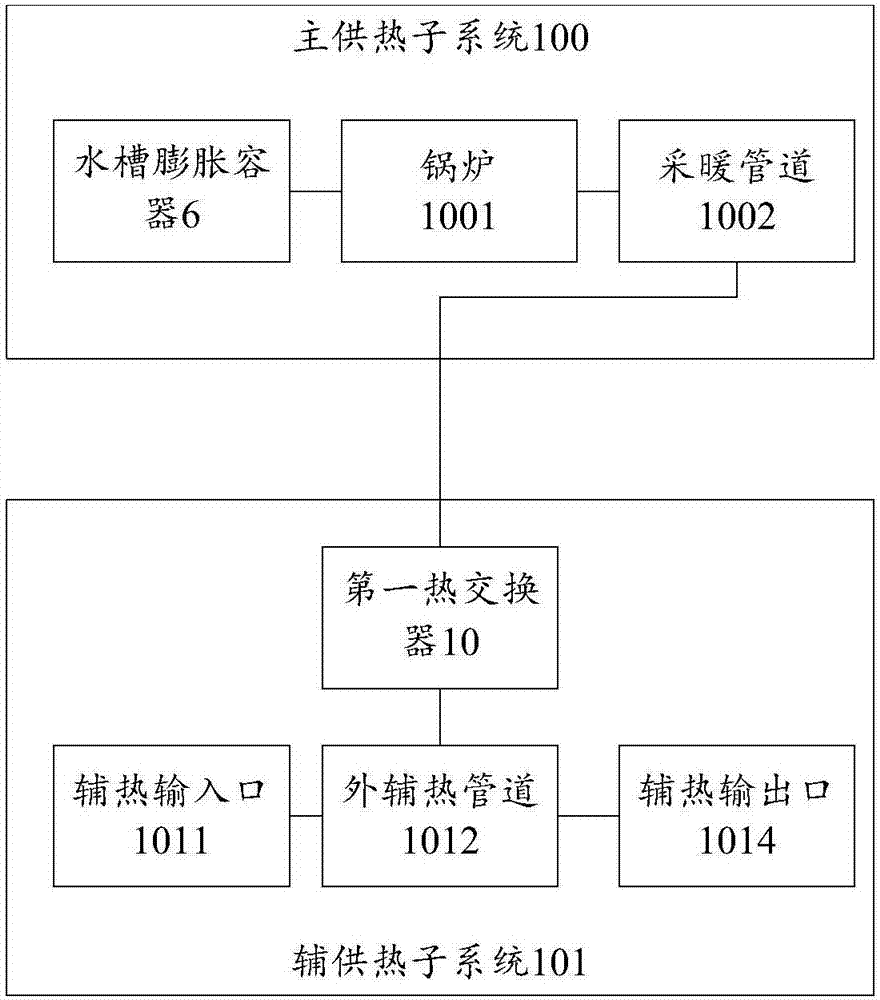

[0032] see figure 1 A structural schematic diagram of a boiler heating system is shown, the system includes: a main heating subsystem 100 and an auxiliary heating subsystem 101;

[0033] Wherein, the main heating subsystem 100 includes a water tank expansion vessel 6, a boiler 1001, and a heating pipeline 1002 connected in sequence; the water tank expansion vessel 6 is provided with a warm water recovery inlet, a water supply port, and a water outlet for boiler water supply; the boiler 1001 heats the water from the tank expansion vessel 6 to a set temperature and then outputs it to the water inlet of the external heating equipment through the heating pipeline 1002; the water outlet of the heating equipment communicates with the warm water recovery water inlet;

[0034] The aforementioned auxiliary heat supply subsystem 101 includes: an auxiliary heat input port 1011 communicated with an external heat recovery source, an external auxiliary heat pipe 1012 connected to the auxili...

Embodiment 2

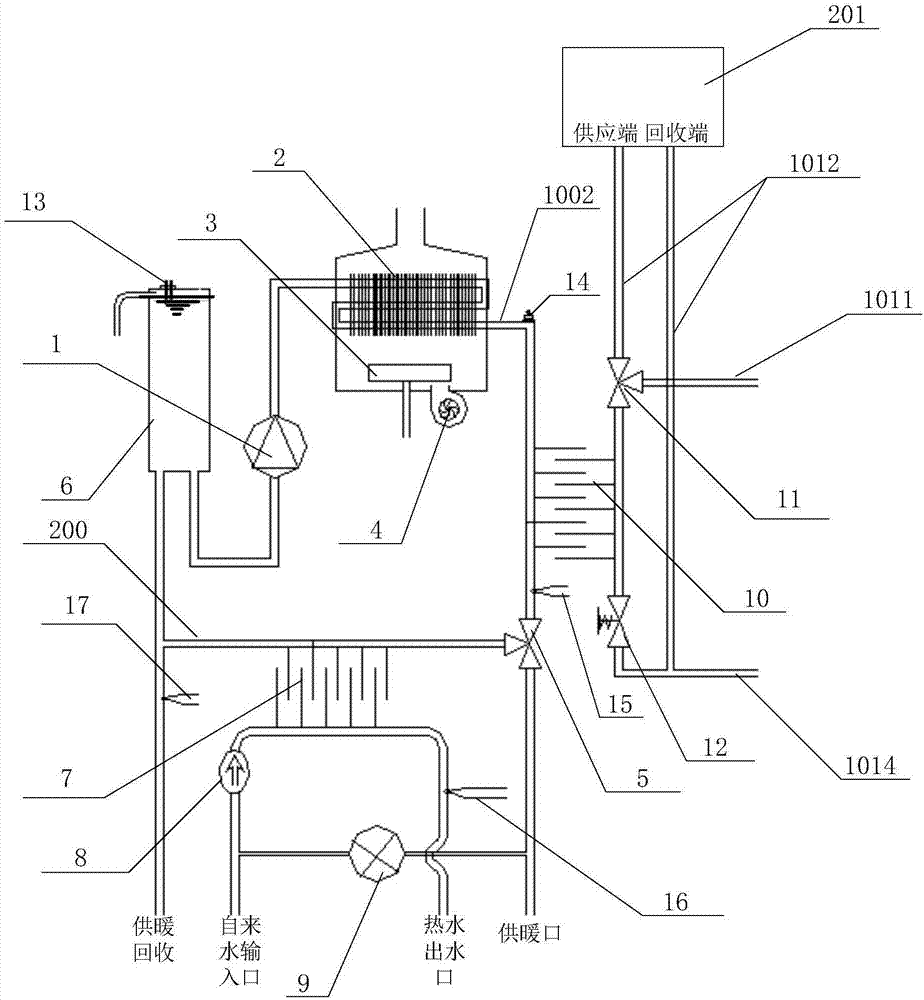

[0040] see figure 2 The specific structural schematic diagram of the first boiler heating system shown, the system includes the boiler heating system provided in the first embodiment above, and also includes the water supply subsystem;

[0041] The hot water supply subsystem includes a hot water supply three-way valve 5 arranged on the heating pipeline, an inner auxiliary heat pipeline 200 connected with the hot water three-way valve, and a second heat exchanger arranged on the inner auxiliary heat pipeline 7; the other end of the internal auxiliary heat pipe 200 is connected to the warm water recovery water inlet (ie figure 2 The heating recovery port in the middle) communicates, and the second heat exchanger 7 is in contact with the tap water outlet pipe, and is used to transfer the heat of the inner auxiliary heating pipe to the tap water outlet pipe.

[0042] Specifically, the above-mentioned three-way valve for hot water supply may be a proportional adjustment three-wa...

Embodiment 3

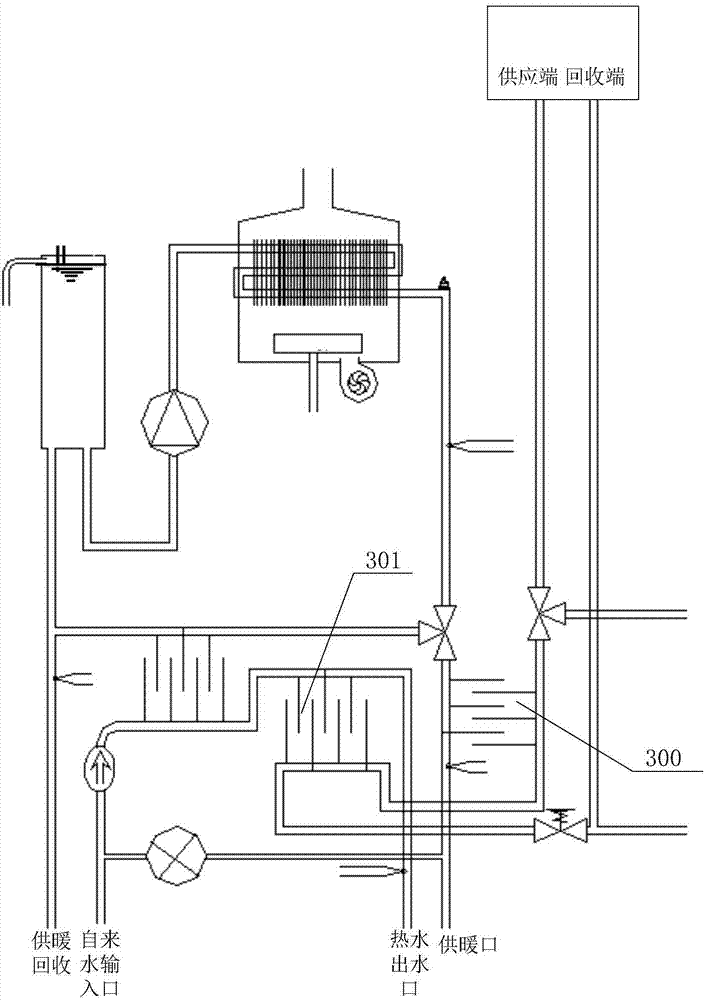

[0055] see image 3 The specific structural schematic diagram of the second type of boiler heating system is shown. This system is based on the first type of boiler heating system provided in the second embodiment above. The above-mentioned first heat exchanger includes a first sub-exchanger 300 and a second sub-switch 301;

[0056] The above-mentioned first sub-exchanger 300 is arranged between the three-way valve for hot water supply and the water inlet (that is, the heating port) of the external heating equipment, and is in contact with the heating pipe; it is used to transfer the heat of the external auxiliary heating pipe to the heating pipe. pipeline.

[0057] The above-mentioned second sub-exchanger 301 is in contact with the tap water outlet pipe, and is used to transfer the heat of the external auxiliary heating pipe to the tap water outlet pipe.

[0058] In addition, a final temperature sensor 302 is provided between the first sub-exchanger and the water inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com