Oscillating wrinkle-removing textile drying device

A drying device and textile technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve problems such as fabric wrinkles, achieve the effect of complete functions, high-efficiency and energy-saving structure, and speed up drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

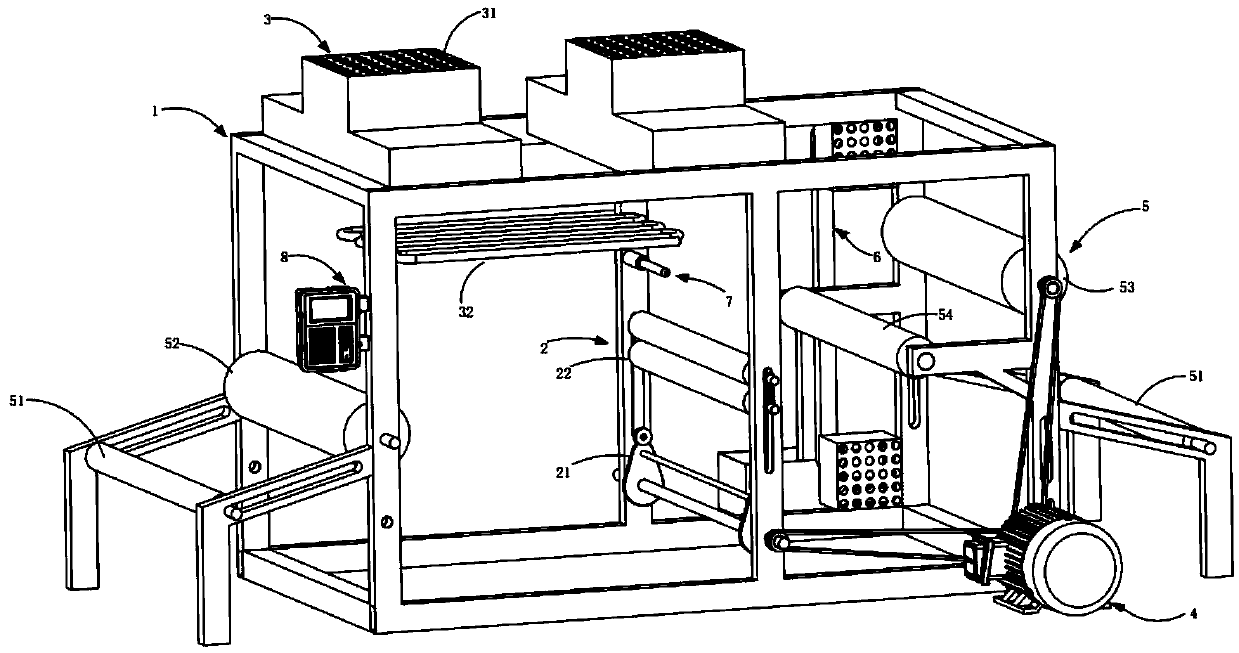

[0033] Such as figure 1 As shown, the present embodiment provides a kind of oscillating wrinkle-removing textile drying device, comprising:

[0034] Rack 1; and

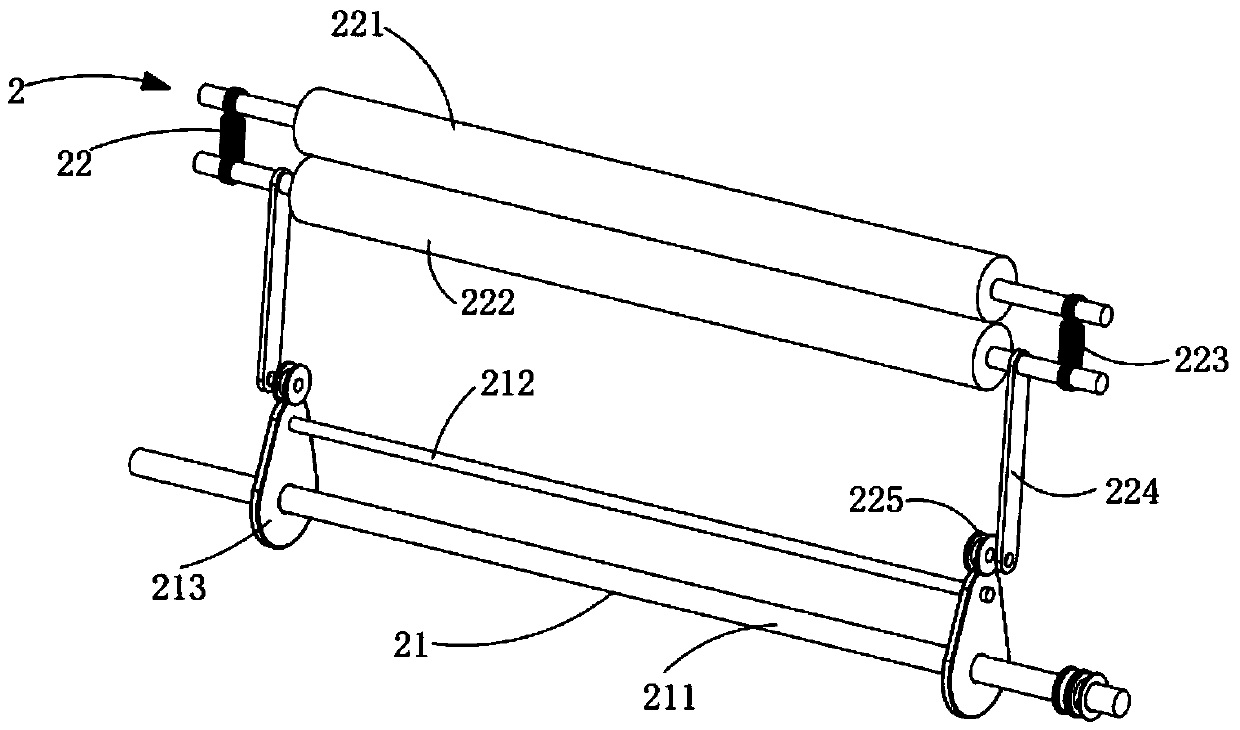

[0035] The oscillating wrinkle removing mechanism 2, the oscillating wrinkle removing mechanism 2 is arranged in the middle of the frame 1, including the oscillating component 21 and the wrinkle removing component 22, the oscillating component 21 drives the wrinkle removing component 22 to slide up and down along the frame 1 to reciprocate and wrinkle remove ;

[0036] A drying mechanism 3, the drying mechanism 3 includes several air blowers 31 and heating coils 32, and the heating coils 32 are arranged between the air blowers 31 and the oscillating wrinkle removing mechanism 2;

[0037] The driving mechanism 4 is connected to the oscillating assembly 21 to drive the oscillating assembly 21 to move.

[0038] It should be noted that the wrinkle removal assembly 22 removes wrinkles from the textile during the up-and...

Embodiment 2

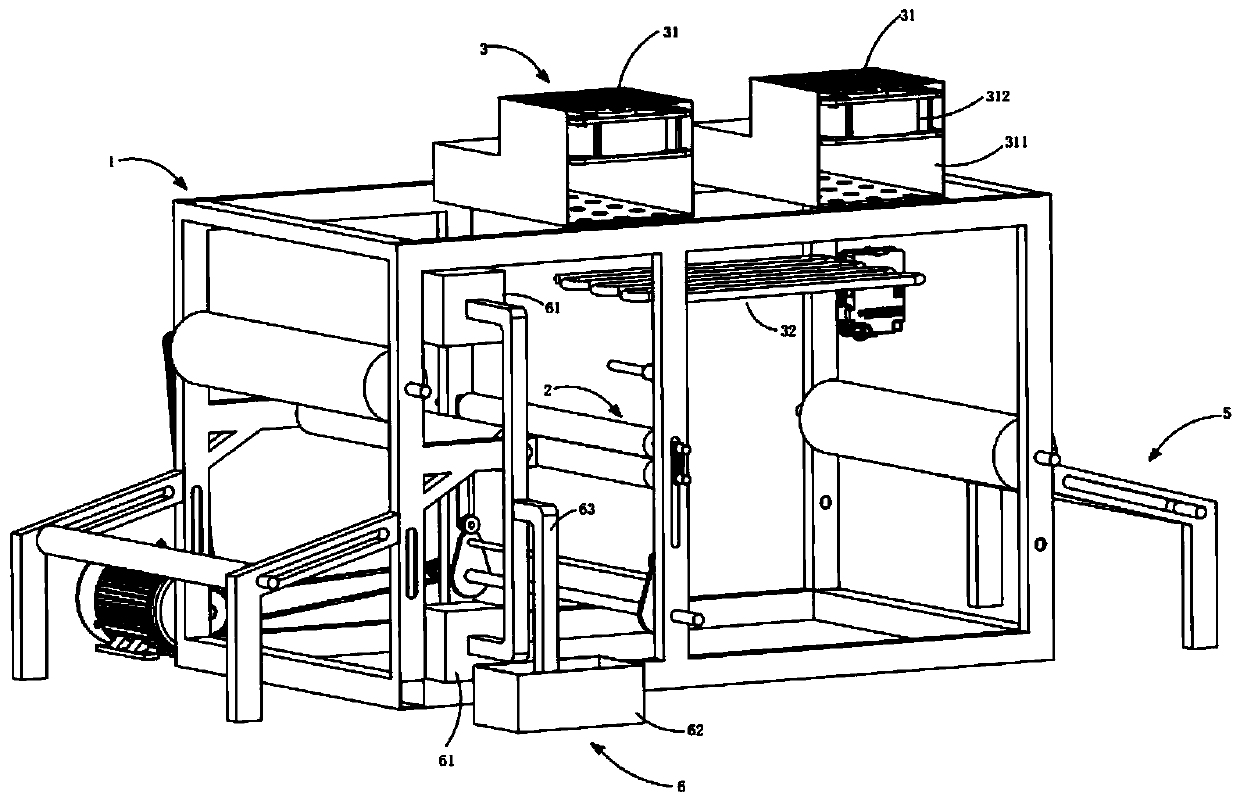

[0071] Such as image 3 and Figure 4 As shown, as an improved technical solution, the described oscillating wrinkle-removing textile drying device also includes an air outlet dust collection mechanism 6 arranged on the right side of the frame 1, and the air outlet dust collection mechanism 6 includes :

[0072] A number of air outlets 61, the number of air outlets 61 are respectively arranged behind the output cloth roller 521 and the driving mechanism 4; and

[0073] Dust collection tank 62, the dust collection tank 62 is arranged on the right side of the frame 1, located at the rear side of the drive motor 41, corresponding to the air outlet 61;

[0074] An air outlet pipe 63 , one end of the air outlet pipe 63 is fixedly connected to the air outlet 61 , and the other end thereof is aligned with the dust collecting groove 62 .

[0075] It should be noted that the air outlet and dust collection mechanism 6 is used to absorb and collect impurities floating in the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com