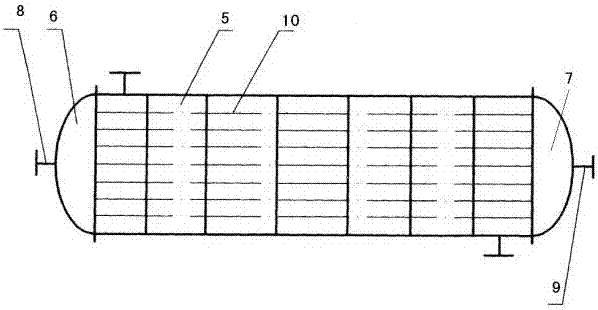

Two-phase flow shell and tube heat exchanger and stabilizing device thereof

A shell-and-tube heat exchanger and stabilizing device technology, applied in the direction of heat exchange equipment safety device, heat exchanger type, heat exchanger shell, etc. The local temperature is too high or too low, the heat exchange is uniform, and the gas phase is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] In this article, if there are no special instructions, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

[0040] Without special instructions, the length unit of the parameters in this application is mm, and the area unit is mm 2 .

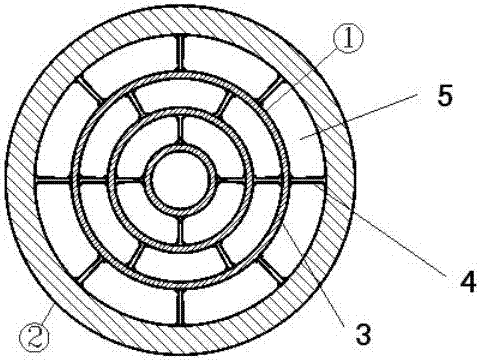

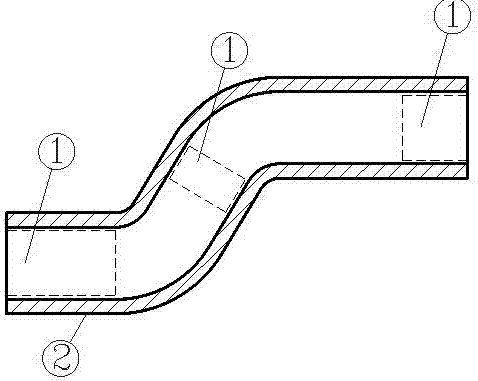

[0041] figure 2 A sleeve-type two-phase flow stabilizing device arranged in a two-phase flow pipeline is shown. The stabilizing device includes a core 1 arranged in the pipeline 2, and the core includes a plurality of concentric tubes 3 and fins 4, the fins 4 are connected to adjacent concentric tubes 3, thereby forming a plurality of small flow channels 11 between the concentric tubes and the fins.

[0042] The above-mentioned two-phase flow stabilization device can separate the two-phase fluid into liquid phase and gas phase, separate the liquid phase into small liquid cluste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com