Patents

Literature

36results about How to "Play a role in stabilizing the flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Current stabilizer spacing change type non-condensable gas tubular heat exchanger

ActiveCN108204751AReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationEngineeringElectrical and Electronics engineering

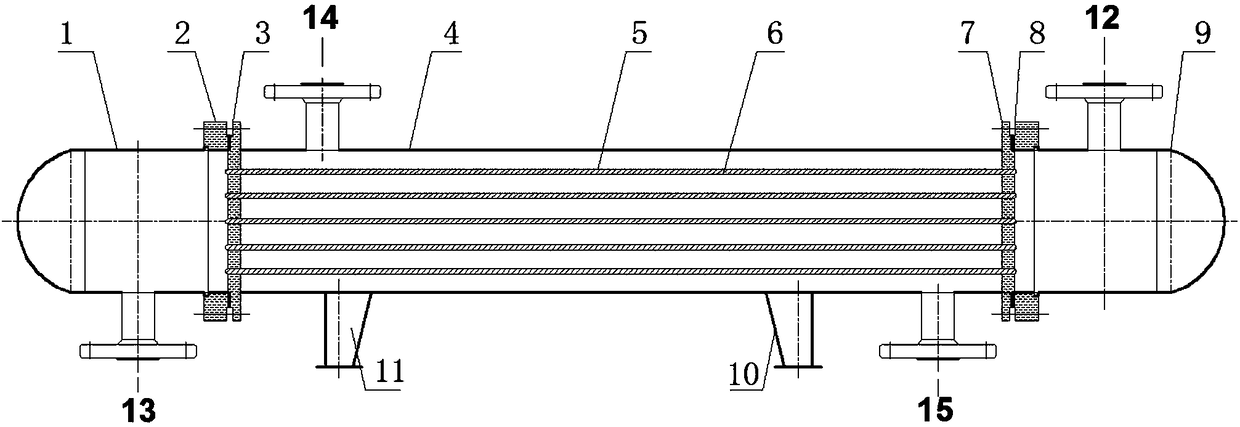

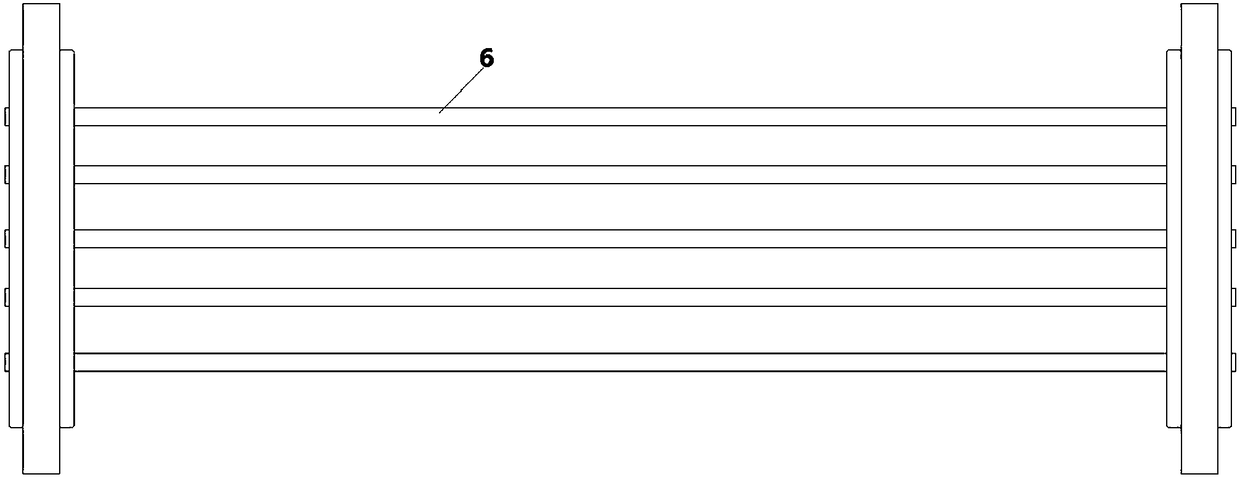

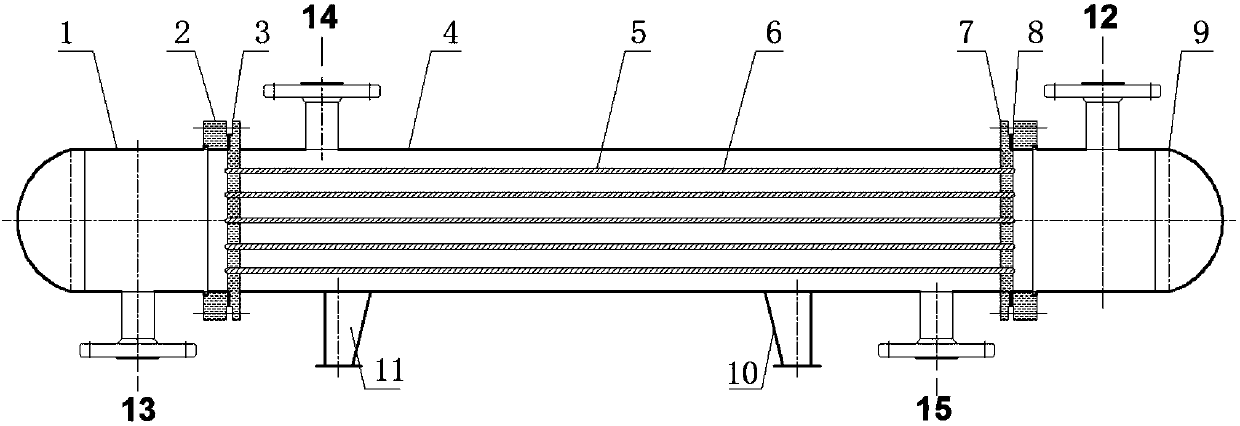

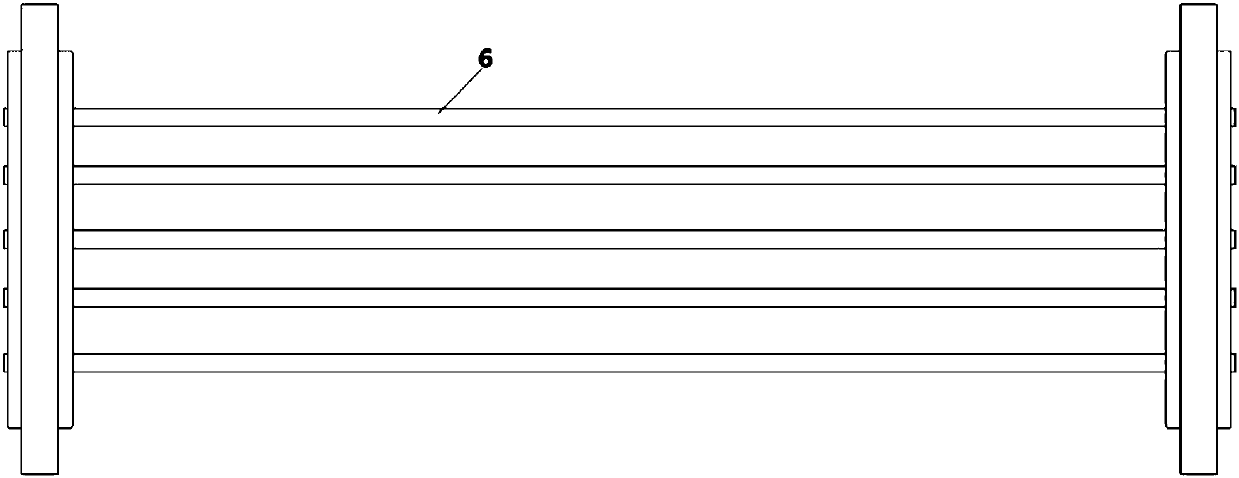

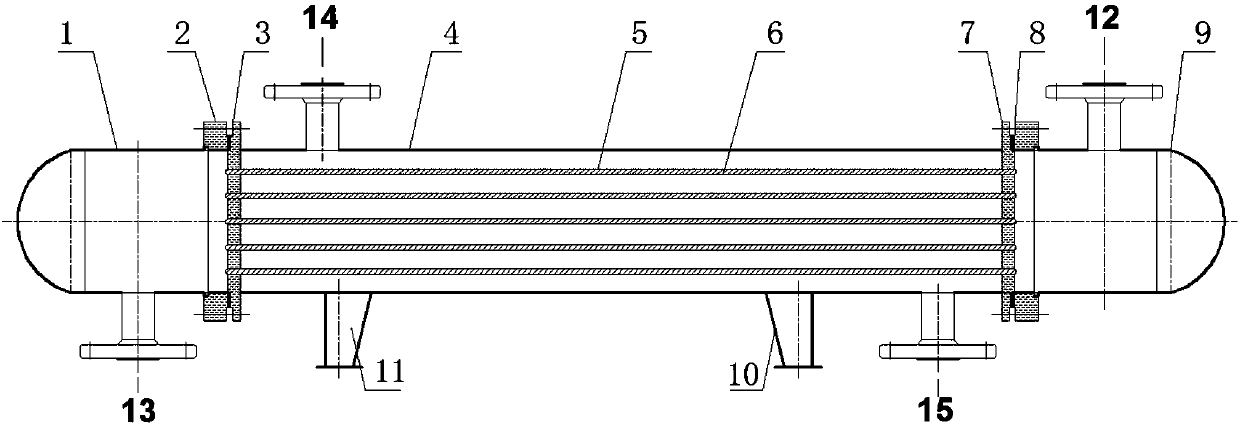

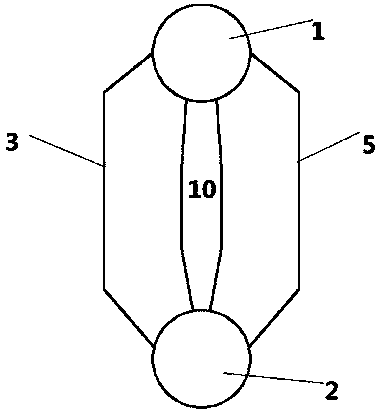

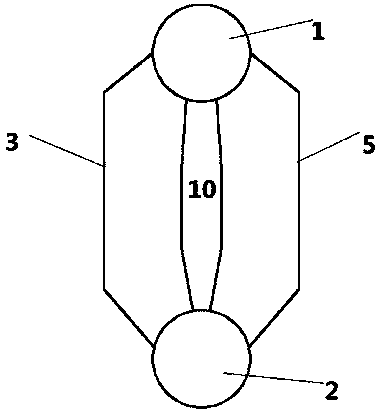

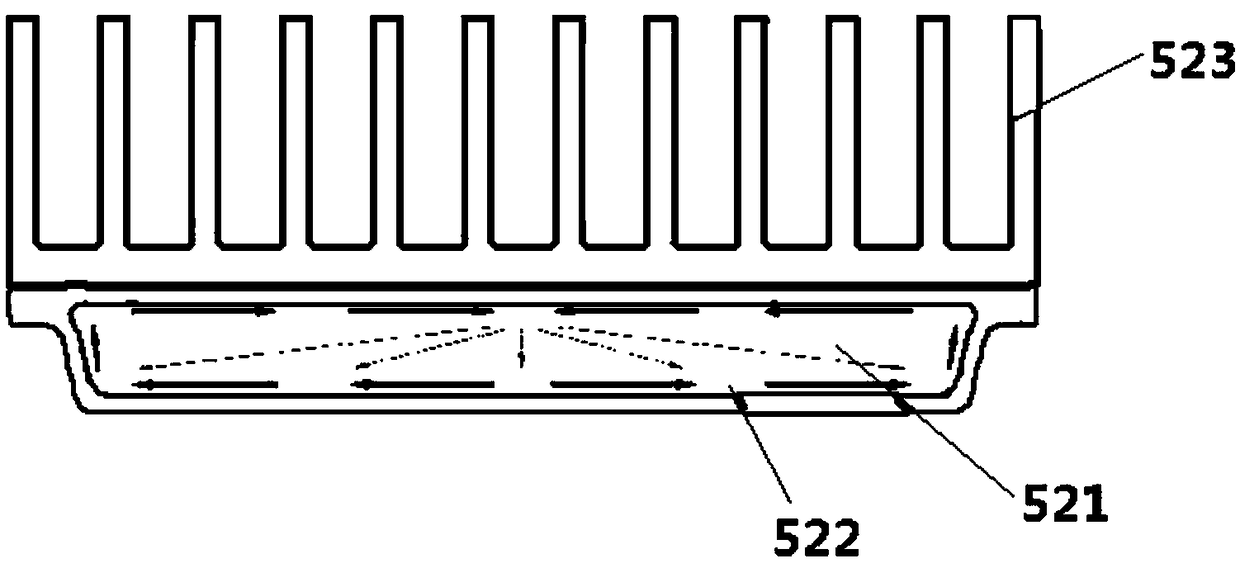

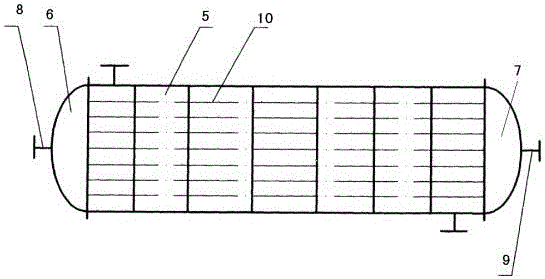

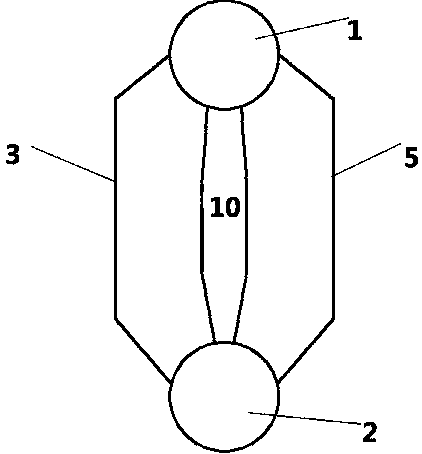

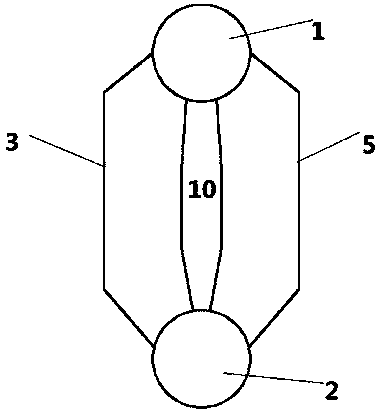

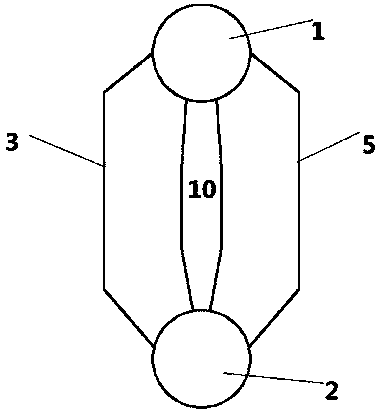

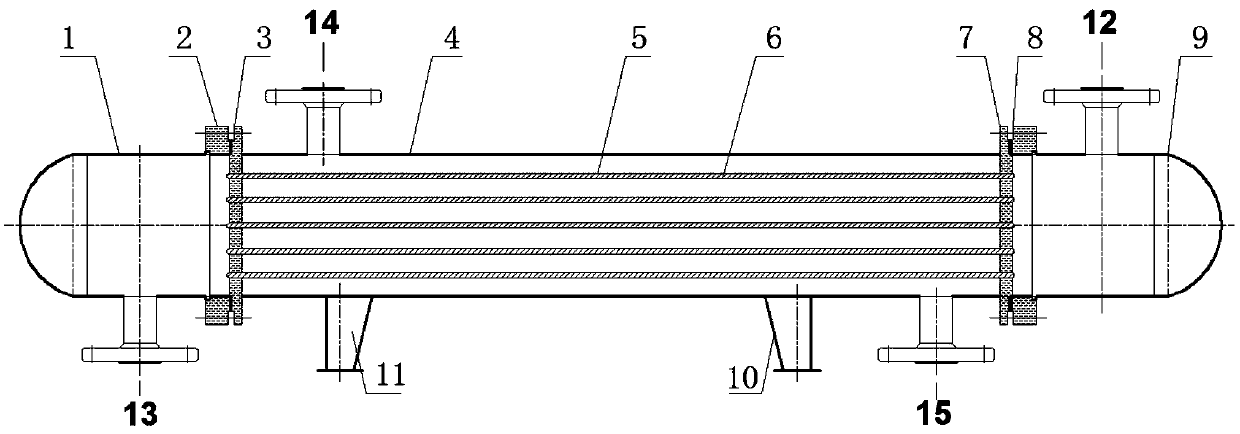

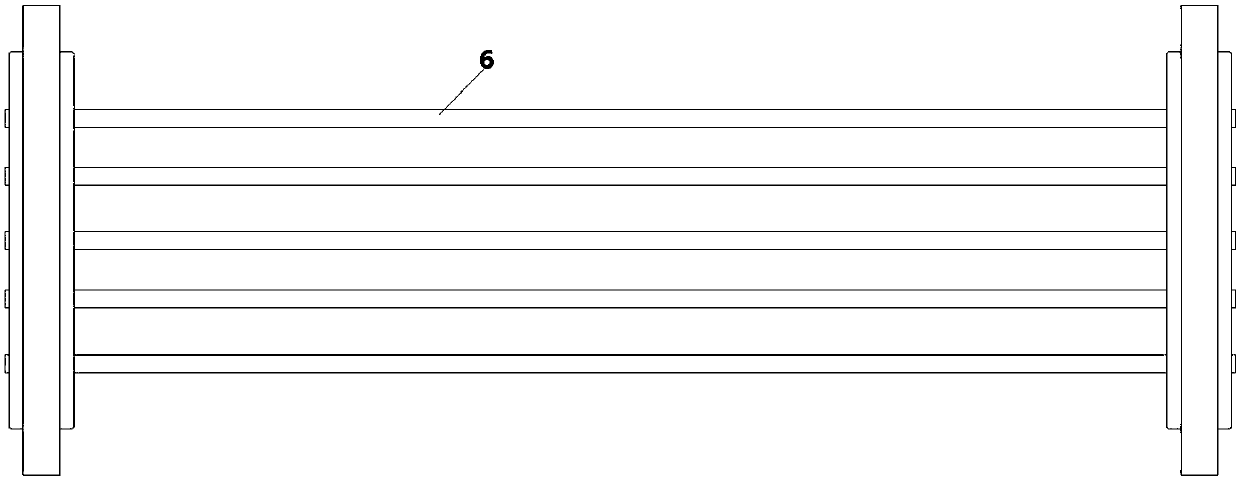

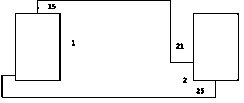

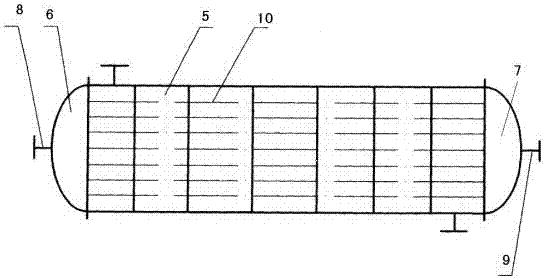

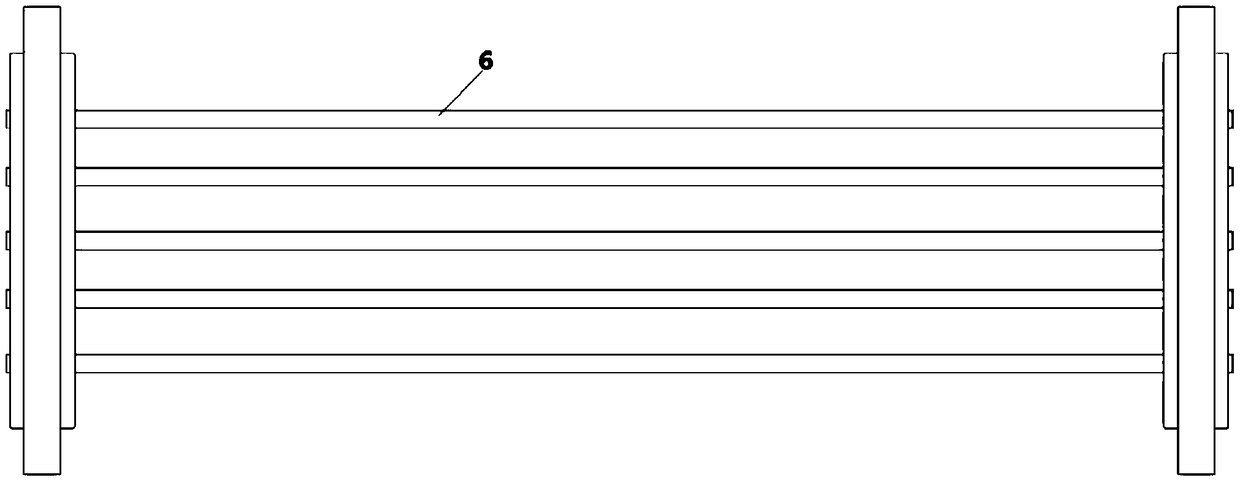

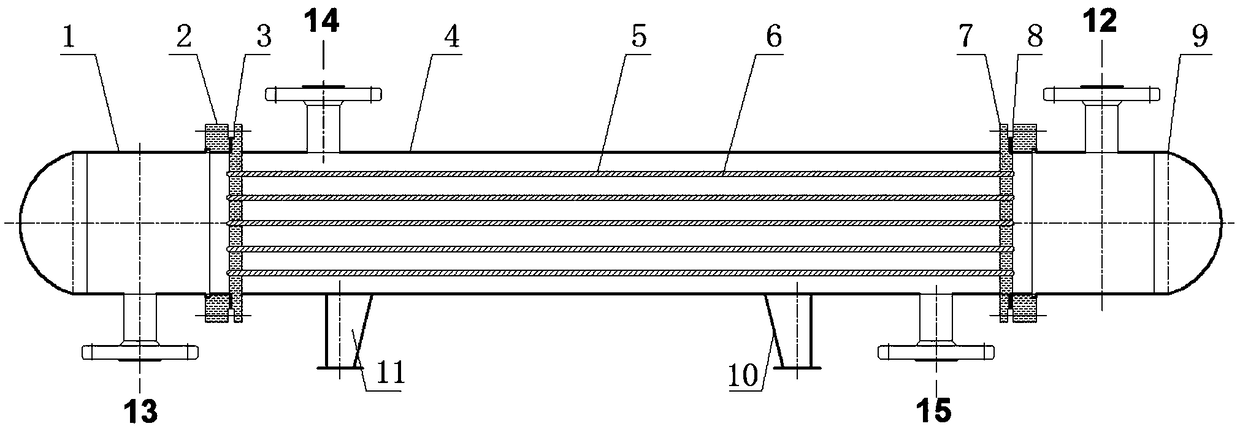

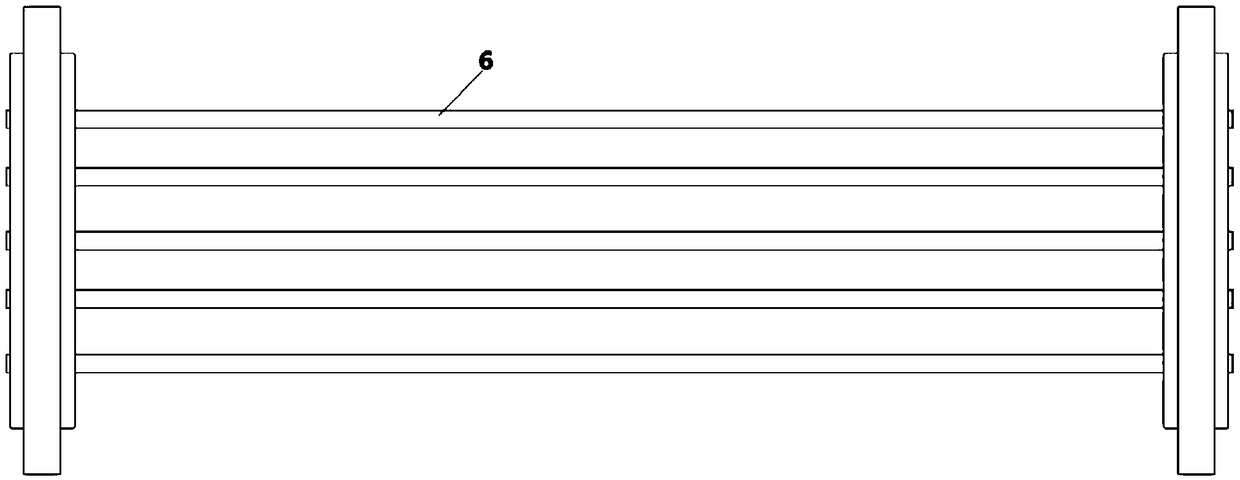

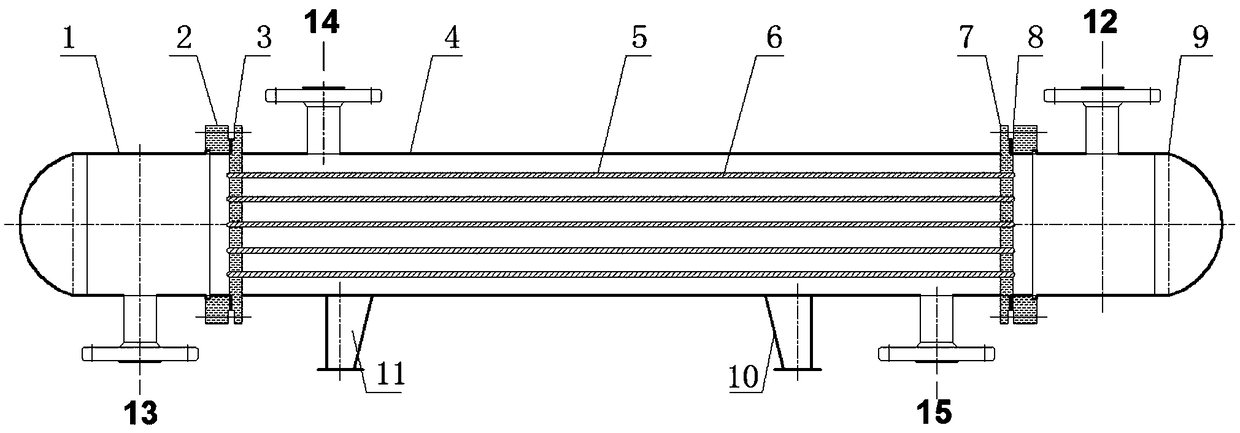

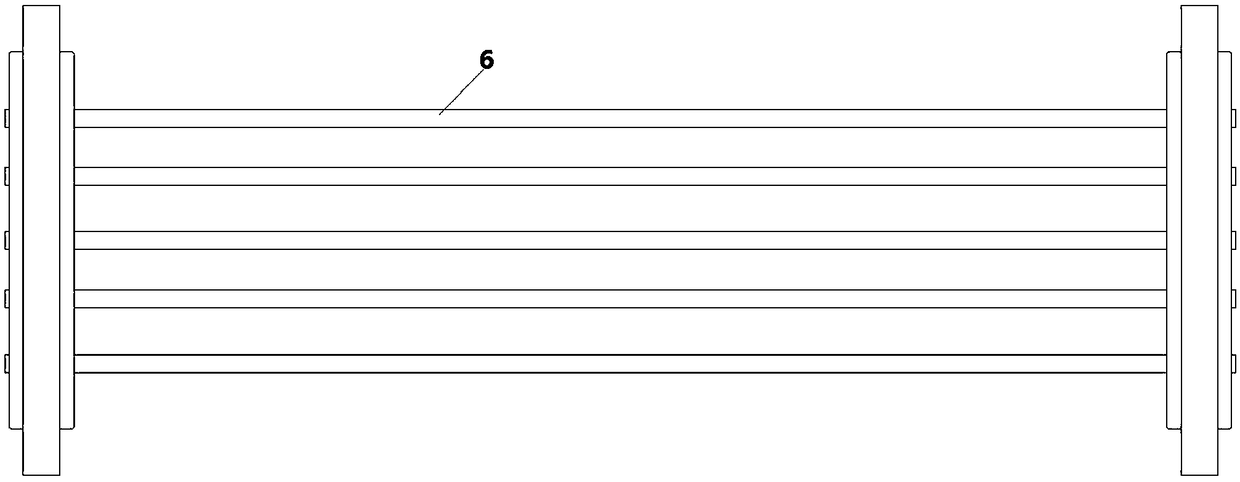

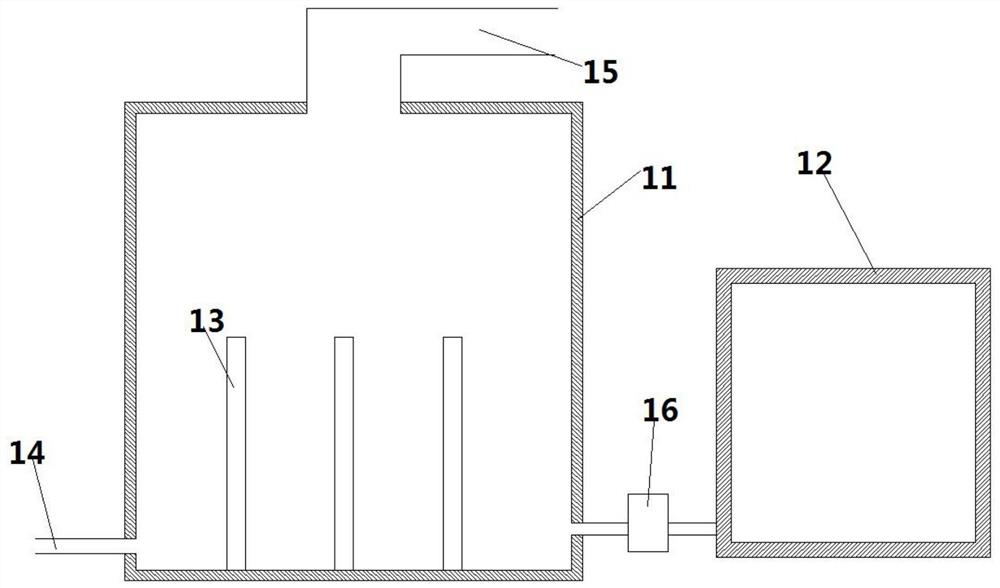

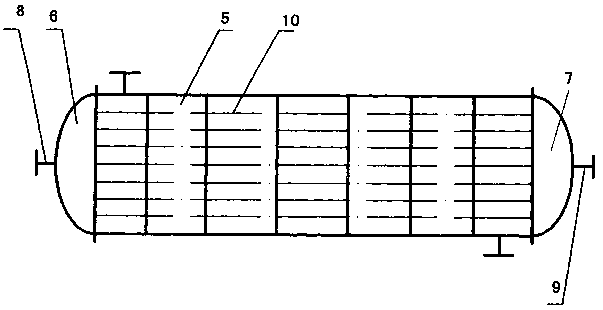

The invention provides a tube-shell heat exchanger. The tube-shell heat exchanger comprises a housing, wherein sealing heads are arranged at two ends of the housing; tube plates are arranged at positions where the sealing heads are connected to the housing; heat exchange tubes are connected to the tube plates at two ends; gas phase in gas-liquid two-phase current is insoluble or slightly-soluble gas, namely, gas cannot dissolve in liquid in the heat exchanging process. The tube-shell heat exchanger is characterized in that current stabilizers for absorbing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of current stabilizers are arranged in one heat exchange tube; the spacing between adjacent current stabilizers gradually increases in the flowing direction of the liquid in the heat exchange tubes until reaching some position, and then the spacing between the adjacent current stabilizers gradually decreases from the some position. According to the heatexchanger, the vibration of pipelines can be minimized based on the spacing change of the current stabilizers while the pipelines are subjected to gas-liquid two-phase flowing, and moreover, the noise level is decreased, and meanwhile, the flowing resistance is reduced.

Owner:山东卓奥环保科技股份有限公司

Flow stabilizer distance enlarging condensable gas heat exchanger

InactiveCN107894178AReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationPlate heat exchangerGas phase

The invention provides a gas-liquid two-phase flow multi-tube type shell-tube heat exchanger. The gas-liquid two-phase flow multi-tube type shell-tube heat exchanger comprises a shell. Sealing heads are arranged at the two ends of the shell correspondingly. Tube plates are arranged at the connecting positions of the sealing heads and the shell. Heat exchange tubes are connected with the tube plates at the two ends, and a gas phase in gas-liquid two-phase flow can be condensed into a liquid phase in the heat exchange process. Each heat exchange tube is internally provided with flow stabilizersfor damping and noise lowering. The same heat exchange tube is internally provided with the multiple flow stabilizers. In the flowing direction of fluid in the heat exchange tubes, the distance between the adjacent flow stabilizers is gradually increased. According to the provided gas-liquid two-phase flow multi-tube type shell-tube heat exchanger, through the length changes of the flow stabilizers, when gas-liquid two-phase flow exists in a pipeline, pipeline vibration is weakened to the maximum degree, the noise level is reduced, meanwhile, flowing resistance is reduced, and the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

Noncondensable-gas tubular heat exchanger with lengths of flow stabilizing devices being variable

InactiveCN107869927AReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationEngineeringFlow resistivity

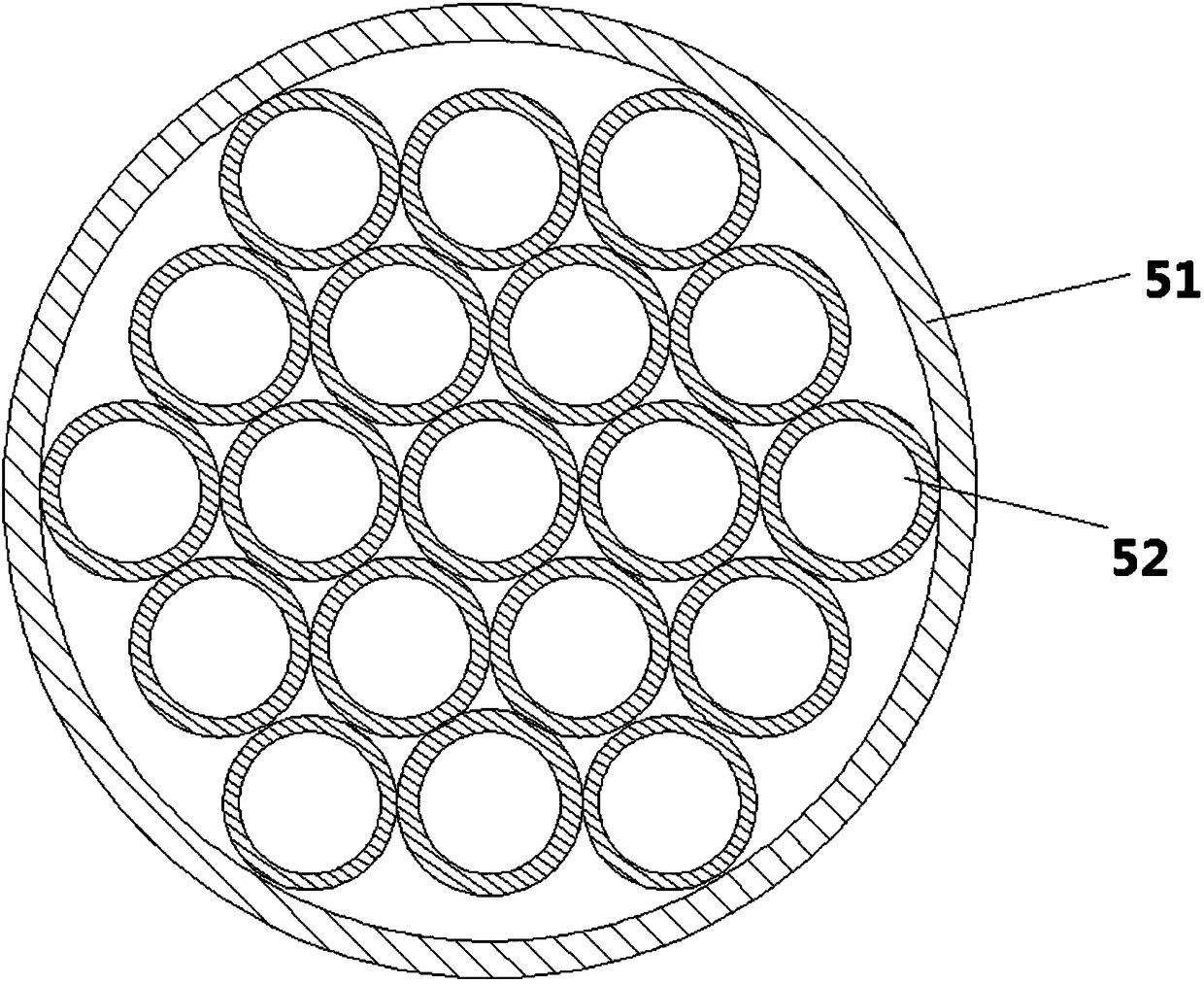

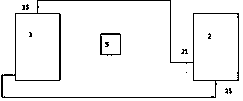

The invention provides a gas-liquid two-phase flow multitube type tubular heat exchanger. The gas-liquid two-phase flow multitube type tubular heat exchanger comprises a shell. The two ends of the shell are each provided with an end enclosure. The connection position of each end enclosure and the shell is provided with a tube plate. Each heat exchange tube is connected with the tube plates at thetwo ends. A gas phase in gas-liquid two-phase flow is insoluble or indissolvable gas, and in other words, in the heat exchange process, the gas is not dissolved into liquid. The gas-liquid two-phase flow multitube type tubular heat exchanger is characterized in that the heat exchange tubes are internally provided with the flow stabilizing devices used for absorbing shock and reducing noise; each heat exchange tube is internally provided with the multiple flow stabilizing devices; and the lengths of the flow stabilizing devices are reduced to a certain position gradually in the flowing direction of fluid inside the heat exchange tubes in the first place, and then the lengths of the flow stabilizing devices are gradually increased from the certain position. According to the gas-liquid two-phase flow multitube type tubular heat exchanger, the lengths of the flow stabilizing devices are variable; when the gas-liquid two-phase flow exists in a pipe, vibration of the pipe is weakened to a greatest extent, and the noise level is lowered; and meanwhile, flow resistance is reduced.

Owner:SHANDONG UNIV

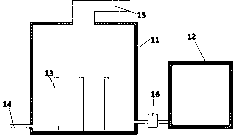

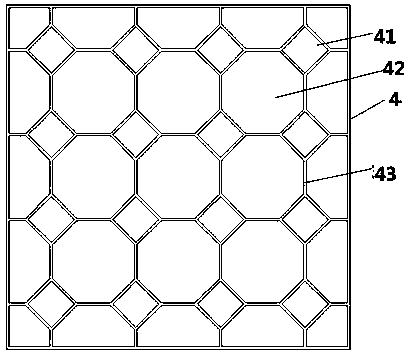

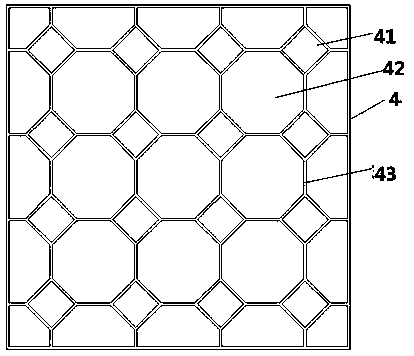

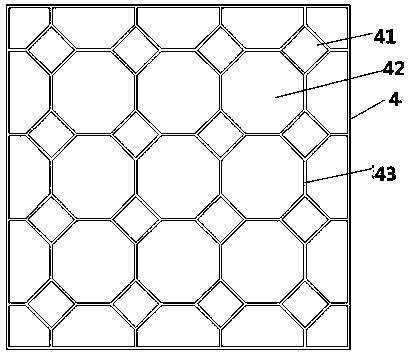

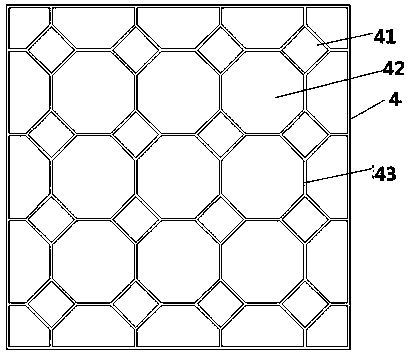

Steam heat exchanger with steady flow structures

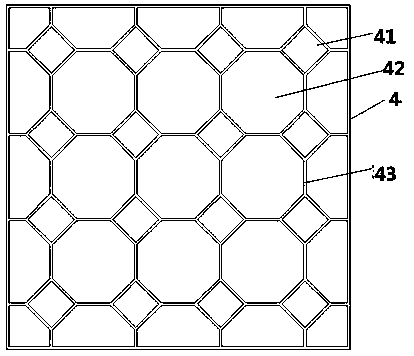

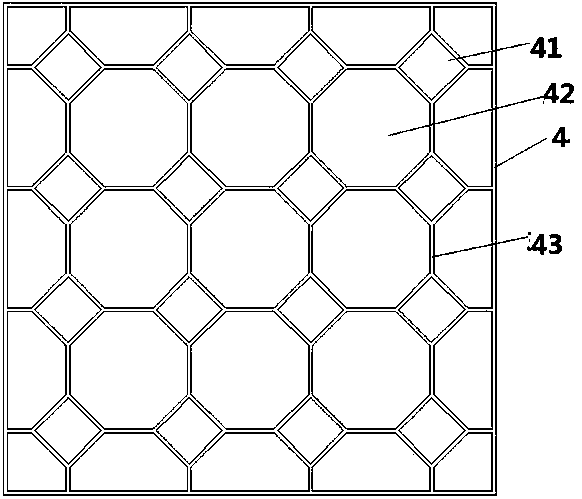

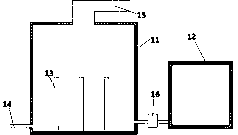

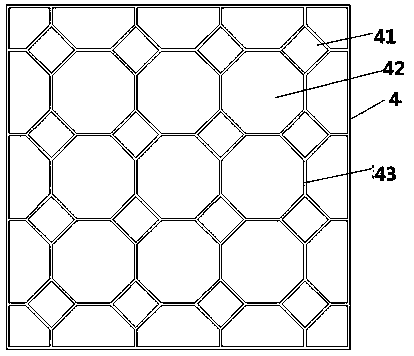

ActiveCN109737368AAvoid or reduce short circuitInhibit refluxSteam generation heating methodsFeed water supplyEngineeringSheet structure

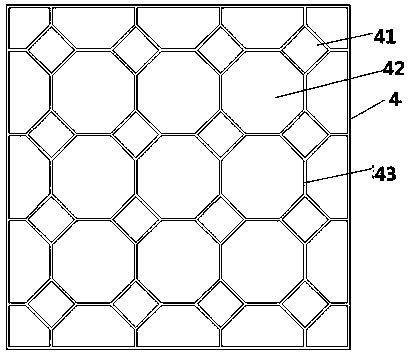

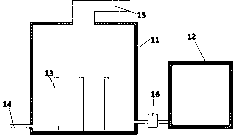

The invention provides a steam heat exchanger. The steam heat exchanger comprises a header and a steam pipe; steady flow devices are arranged inside the steam pipe and are each of a sheet structure; the sheet structures are arranged on the cross section of the steam pipe; the steady flow devices are composed of square through holes and right octagon through holes; the length of each side of the square through holes is equal to the length of each side of the right octagon through holes; the four sides of each square through hole are the sides of four different right octagon through holes; and the four spaced sides of each right octagon through hole are the sides of four different square through holes. Compared with a steady flow device in the prior art, the steam heat exchanger with the steady flow structures further improves the steady flow effect, enhances heat transfer and is easy to manufacture.

Owner:青岛鑫众合贸易有限公司

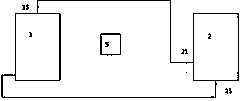

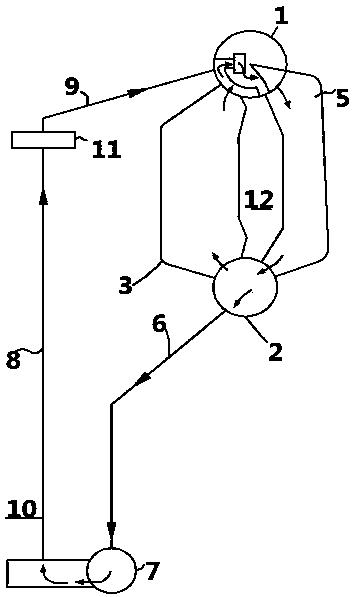

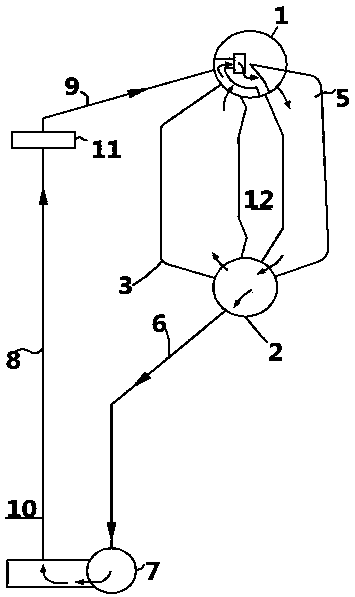

Flow stabilizing device and design method for steam boiler with optimized pipe diameter

ActiveCN110285399AAvoid or reduce short circuitInhibit refluxBoiler water tubesWater-tube boilersNoise levelEngineering

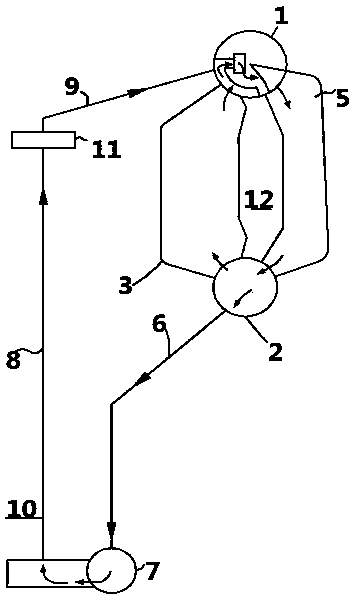

The invention provides a design method for a steam boiler. The steam boiler comprises an upper boiler cylinder, a lower boiler cylinder, an ascending pipe and a descending pipe, wherein the ascending pipe and the descending pipe are connected between the upper boiler cylinder and the lower boiler cylinder, and flow stabilizing devices are arranged in the ascending pipe. The design method comprises the following step that along with the increase of the pipe diameter of the ascending pipe, the distance between the adjacent flow stabilizing devices is continuously reduced. According to the provided design method for the steam boiler with the flow stabilizing devices with novel structures, the boiler which is designed by using the method has the advantages that when the steam and liquid two phases flow in the ascending pipe, the heat transfer is enhanced, meanwhile, the vibration of the ascending pipe is weakened, and the noise level is reduced.

Owner:佛山市佳燊金属制品有限公司

Optimization design method of spacing between lifting pipes

ActiveCN109882821AImprove heat transfer effectAvoid or reduce short circuitBoiler water tubesWater-tube boilersEngineeringDesign methods

The invention provides a design method of a steam boiler. The steam boiler comprises an upper boiler cylinder, a lower boiler cylinder, lifting pipes and falling pipes, wherein the lifting pipes and the falling pipes are connected between the upper boiler cylinder and the lower boiler cylinder. The design method comprises the steps that with the increase of the lifting pipe diameter, the lifting pipe spacing increases continuously. The change of a law is obtained by a large number of numerical simulation and experiments, and through the changes of the law, the heat transfer effect can be further improved.

Owner:江苏宝利晶石英材料股份有限公司

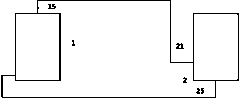

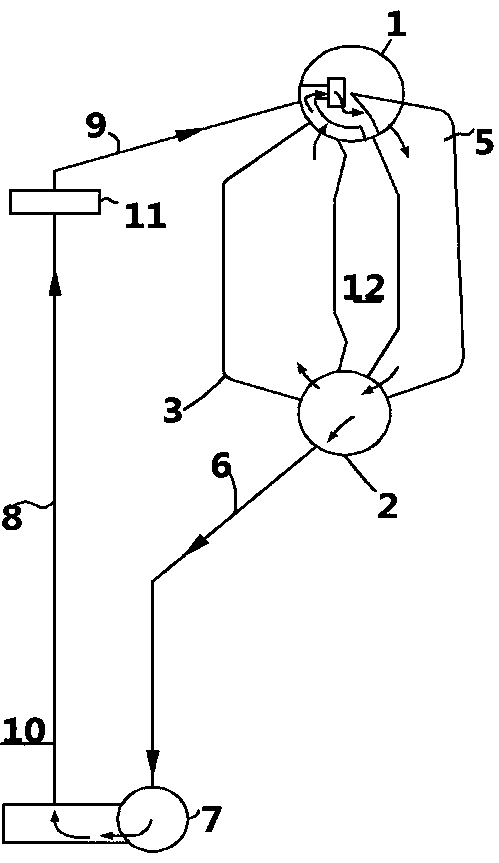

Steady flow evaporator and seawater desalination system

ActiveCN109231320AReduce water hammerImprove utilizationGeneral water supply conservationSeawater treatmentEvaporationEngineering

The invention provides a steady flow evaporator. The steady flow evaporator comprises an inlet header, an outlet header, and a heat exchange component connected between the inlet header and the outletheader, wherein the inlet header and the outlet header are respectively connected with a steam inlet pipe and a condensate outlet pipe; the steam inlet pipe of the inlet header is internally providedwith a flow stabilizer, and the flow stabilizer has a sheet structure; the sheet structure is arranged on the cross section of the steam inlet pipe; the flow stabilizer is formed by a square structure and a regular octagonal structure, so that a square through hole and a regular octagonal through hole are formed. The flow stabilizer with the novel structure is adopted, namely, a flow stabilizer in a loop heat pipe is subjected to field transfer and is applied to an inlet pipe at an evaporation end of the loop heat pipe, so that a water hammer phenomenon caused by the space expansion when a steam-water mixture enters the inlet header can be reduced.

Owner:SHANDONG UNIV

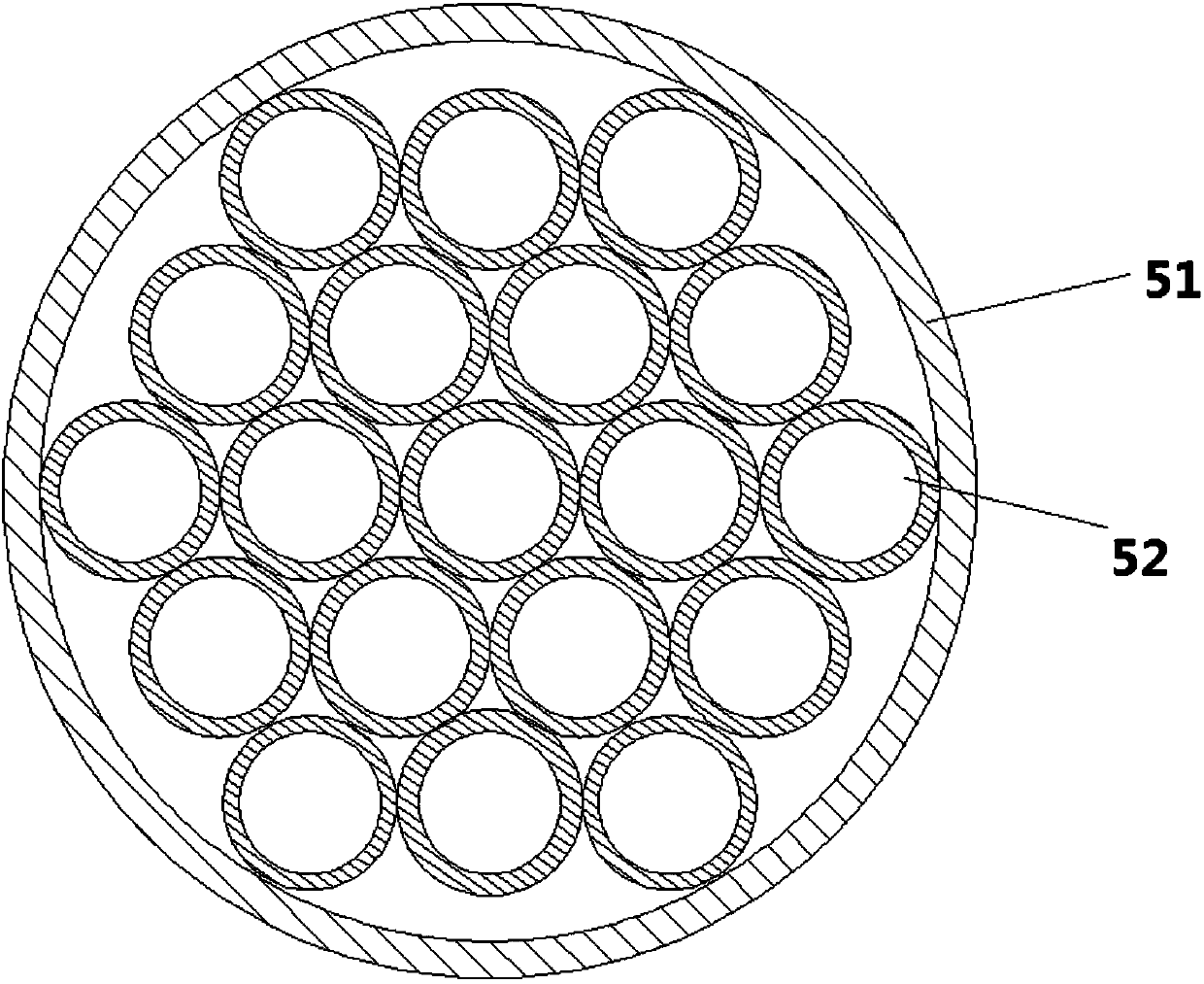

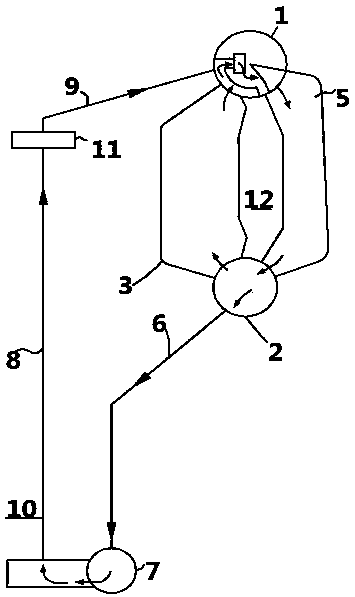

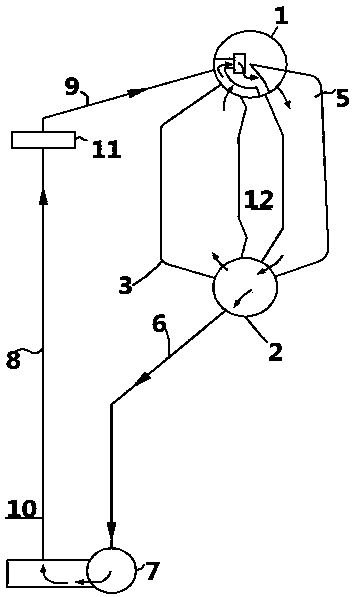

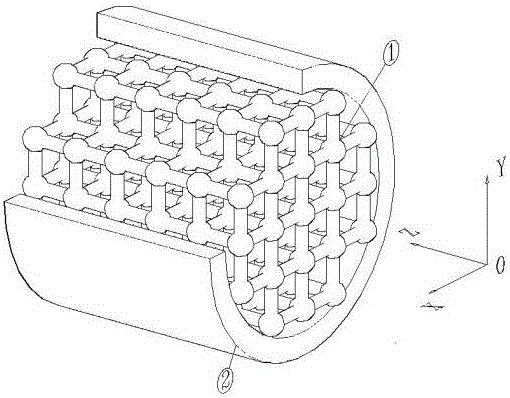

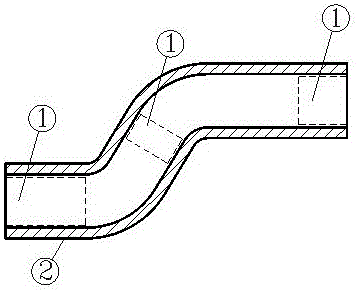

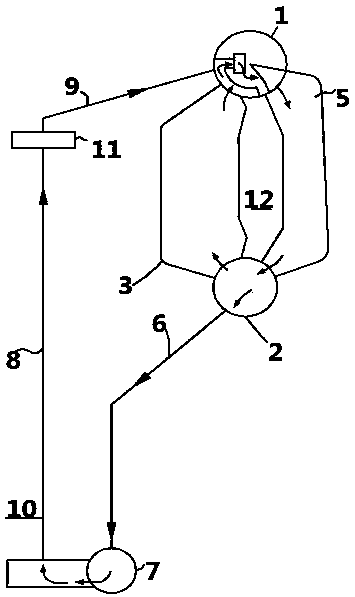

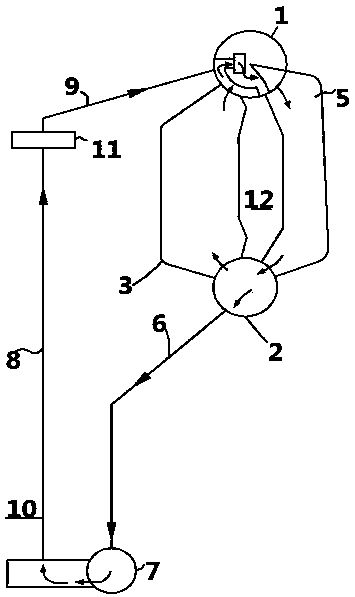

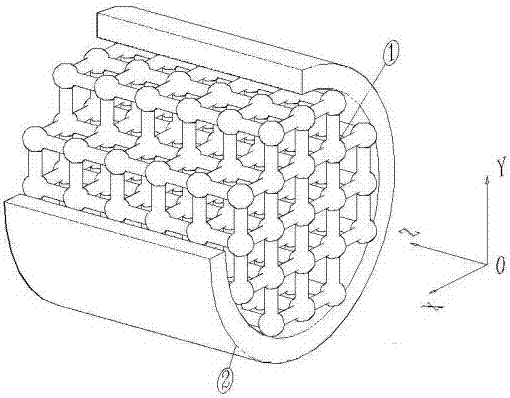

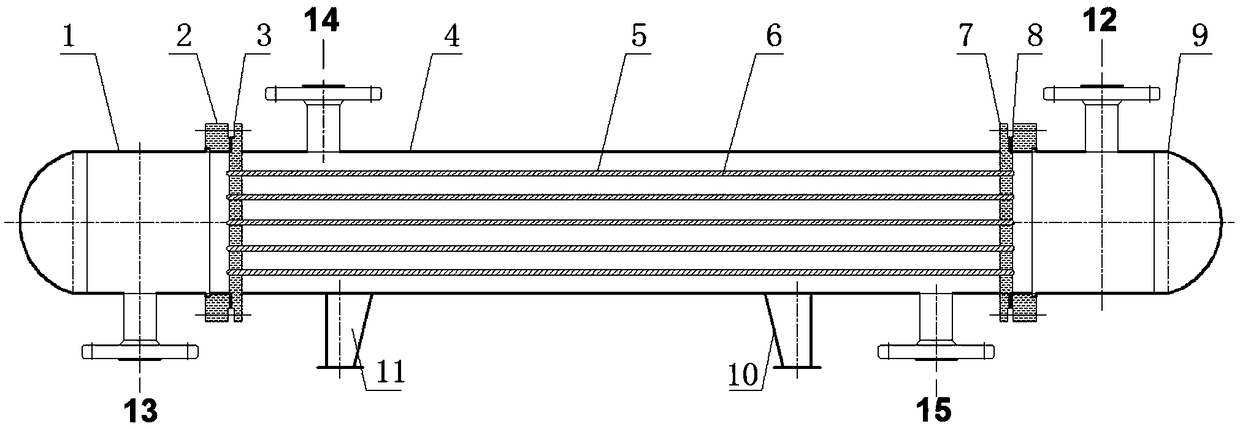

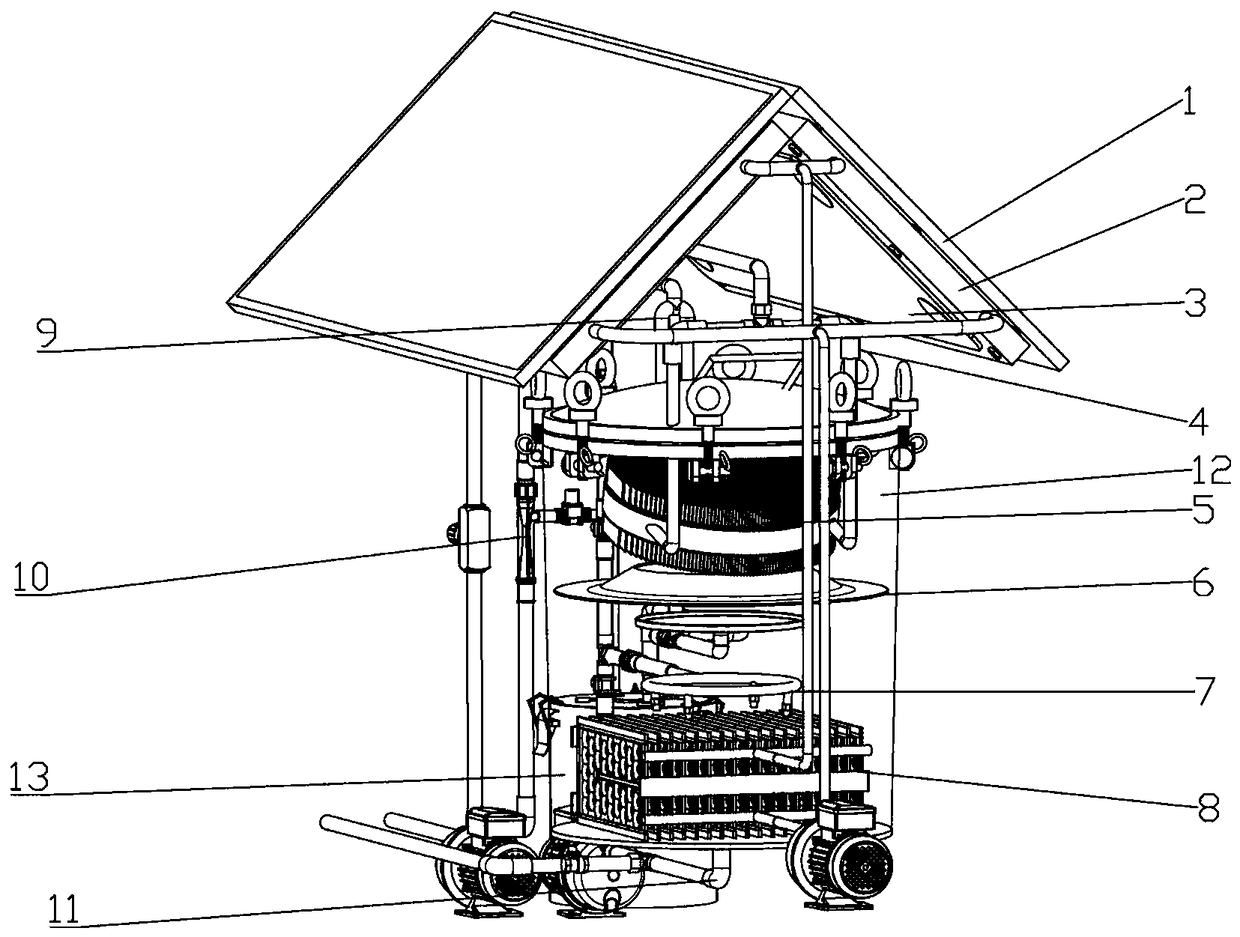

Heat exchanger system provided with multiple two-phase flow stabilizing devices and pipeline of heat exchanger system

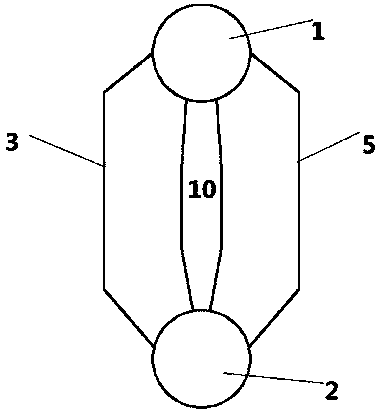

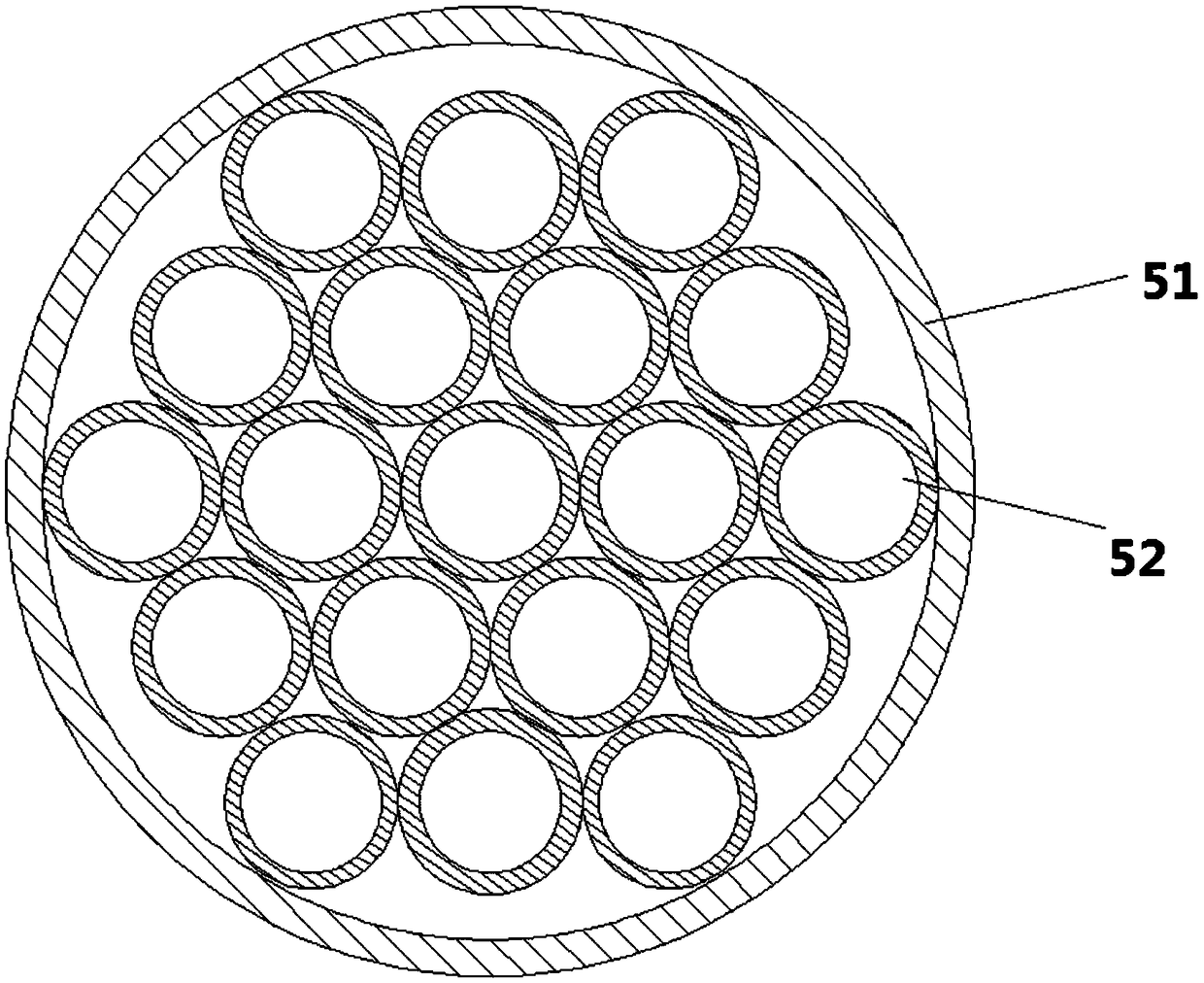

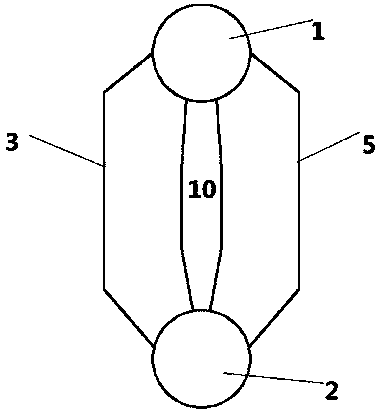

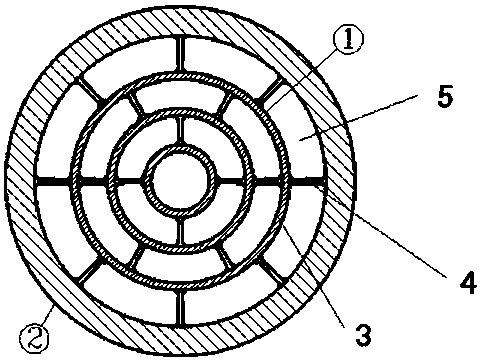

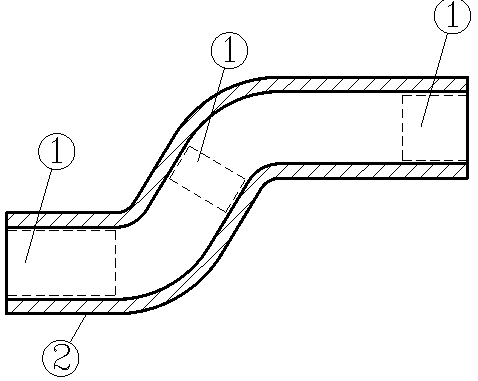

The invention provides a heat exchanger system provided with a plurality of two-phase flow stabilizing devices and a pipeline of the heat exchanger system. The two-phase flow stabilizing devices are arranged in the pipeline; each of the two-phase flow stabilizing devices comprises a core body; the core body can divide two phase flow runners in the pipeline into a plurality of small runners; and the two-phase flow stabilizing devices are continuously arranged or arranged at intervals. According to the invention, the two-phase flow stabilizing devices are continuously arranged or arranged at intervals, so that the liquid phase and the gaseous phase can be separated through a plurality of stages and steps, heat transfer can be further enhanced, and the effects of vibration and noise reduction are realized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Design method of steam boiler with changeable ascending pipe

ActiveCN111207376AReduce vibrationImprove heat transfer performanceBoiler water tubesWater-tube boilersEnhanced heat transferMechanical engineering

The invention provides a design method of a steam boiler with a changeable ascending pipe. The steam boiler comprises an upper boiler barrel, a lower boiler barrel, the ascending pipe and a descendingpipe, wherein the ascending pipe and the descending pipe are connected between the upper boiler barrel and the lower boiler barrel, and the pipe diameter of the ascending pipe is continuously increased in the flowing direction of fluid. According to the design method of the steam boiler with a flow stabilizing device of a novel structure and the boiler designed through the method, when vapor-liquid two-phase flow exists in the ascending pipe, heat transfer is enhanced, meanwhile, vibration of the ascending pipe is weakened, and the noise level is lowered.

Owner:SHAOXING MINGLIANG TECH INFORMATION CONSULTING CO LTD

A Steam Boiler with Varying Downpipe Diameter

ActiveCN110067993BUniform pressure distributionUniform heat exchangeSteam generation using pressureHeat transfer modificationThermodynamicsEngineering

The invention provides a steam boiler. The steam boiler comprises an upper pot cylinder, a lower pot cylinder, a rising pipe and a downcomer, wherein the rising pipe and the downcomer are connected between the upper pot cylinder and the lower pot cylinder, and along the flowing direction of the fluid in the reducing pipe, the pipe diameter of the downcomer is continuously reduced. Due to the factthat the downcomer is continuously descended, the change of the fluid volume and the pressure continuously changed is met, so that overall pressure distribution is uniform, heat exchange is uniform, materials can be saved, and the cost is reduced.

Owner:济南济锅华源锅炉有限责任公司

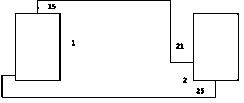

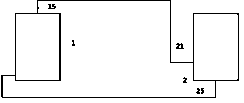

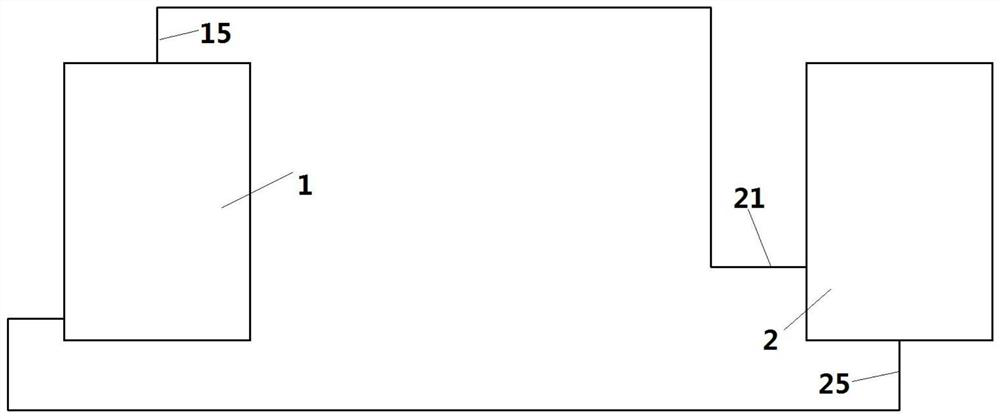

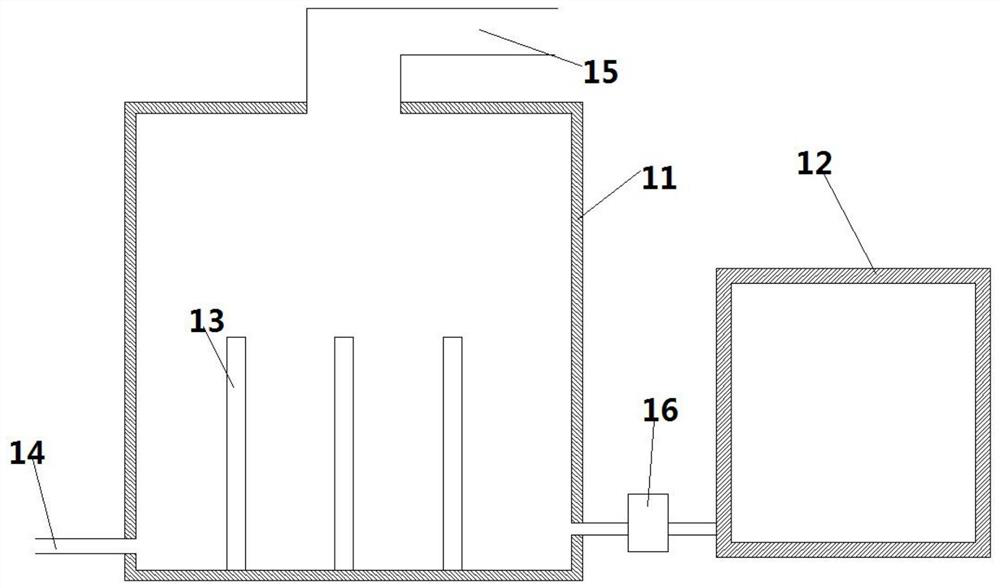

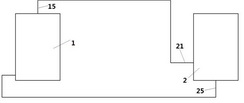

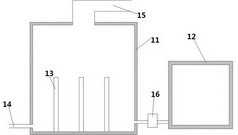

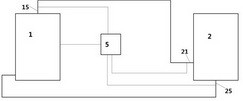

An evaporator system for heating liquid medicine

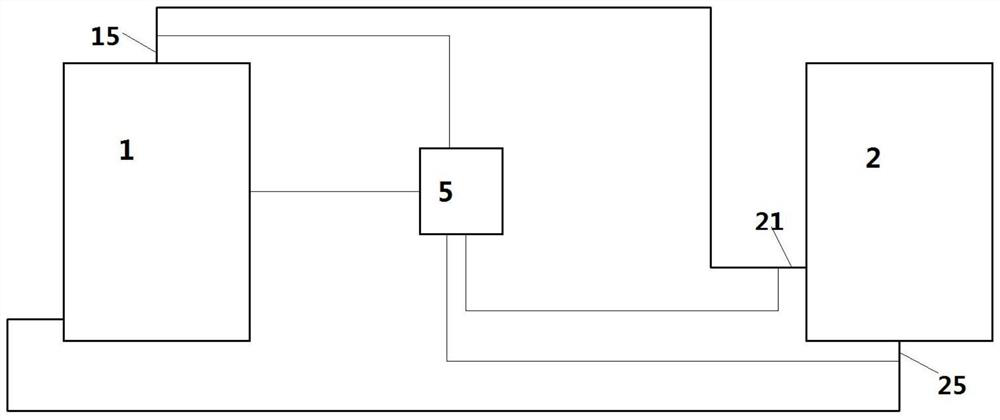

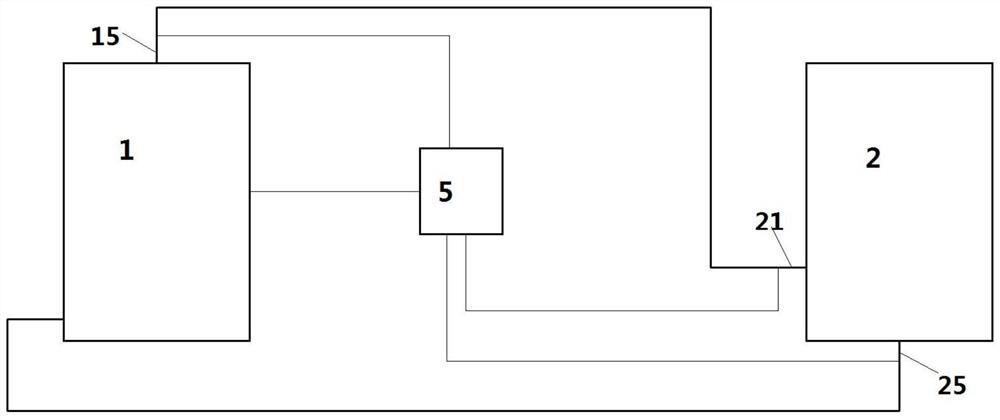

ActiveCN109489024BAvoid lostImprove intelligenceSteam generation heating methodsBoiler water tubesData connectionEngineering

The invention discloses an evaporator system. The evaporator system comprises an evaporator body and a steam utilization device, steam generated by heating in the evaporator enters the steam utilization equipment through a steam inlet pipe, after full heat exchange is carried out in the steam utilization equipment, the steam is circularly back into the evaporator body for heating; the evaporator body comprises a steam chamber, an electric heating device is arranged in the steam chamber, a steam outlet pipeline is arranged at the upper part of the steam chamber, and a water inlet pipeline is arranged in the steam chamber; a temperature sensor is arranged in the steam inlet pipe and used for measuring the temperature of the steam in the steam inlet pipe; and the temperature sensor, the electric heating device is in data connection with a controller, the controller automatically controls the heating power of the electric heating device according to the temperature measured by the temperature sensor. According to the evaporator system, the heating power is controlled, the inlet temperature is ensured to meet the requirements, the inlet temperature is prevented from being too high to cause the heat loss, the inlet temperature is prevented from being too low to cause that the heat does not meet the actual requirements, so that the intelligence of the system is improved.

Owner:青岛鑫众合贸易有限公司

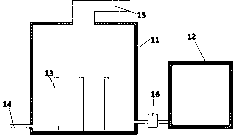

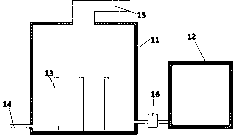

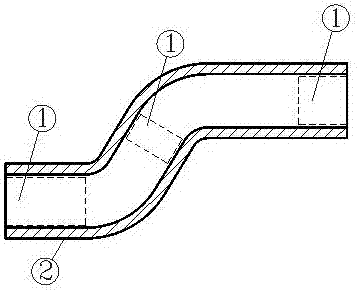

A pipe-connected steam heat exchanger

ActiveCN110067995BUniform pressureIncrease the heat exchange areaSteam generation heating methodsBoiler water tubesMechanical engineeringHeat exchanger

The invention provides a vapor heat exchanger. The vapor heat exchanger comprises a collecting box and steam tubes, wherein the steam tubes upwards extend from the collecting box; a steam inlet and acondensed water outlet are formed in the collecting box; steam enters the collecting box, and upwards flows from the collecting box to enter the steam tubes; the steam tubes perform heat exchange withoutside to form condensed water; condensed water returns into the collecting box under action of the gravity, and flows out from a water return hole in the lower part of the collecting box; a communication tube is arranged between at least two adjacent steam tubes of the multiple steam tubes; multiple communication tubes are arranged between adjacent steam tubes from the lower parts of the steamtubes to the upper parts of the steam tubes; and the diameters of the communication tubes are continuously increased from the lower parts of the steam tubes to the upper parts of the steam tubes. Along with upward flow of fluid, fluid continuously releases heat, and released heat in different heat collecting tubes becomes more and more uniform, and therefore, pressure balance can be guaranteed tobe reached as quickly as possible in a fluid flowing process.

Owner:YANTAI MOON HEAT EXCHANGE TECH

Steam boiler

ActiveCN109945148AAvoid or reduce short circuitInhibit refluxSteam generation using pressureSteam boilersEngineeringSheet structure

The invention provides a steam boiler. The steam boiler comprises an upper drum, a lower drum, and an ascending pipe and a descending pipe connected between the upper drum and the lower drum; a flow stabilizing device is arranged in the ascending pipe, and is of a sheet structure; the sheet structure is arranged on the cross section of the ascending pipe; the flow stabilizing device consists of square through holes and regular octagonal through holes; the edge length of the square through holes is equal to the edge length of the regular octagonal through holes; four edges of the square throughholes are edges of four different regular octagonal through holes; and four spaced edges of the regular octagonal through holes are edges of four different square through holes. The steam boiler is provided with the new-structured flow stabilizing device; and when steam and liquid phases flow in the ascending pipe, the heat transfer is intensified, and meanwhile, the vibration of the ascending pipe is weakened to reduce the nose level.

Owner:沭阳绿动新能源有限公司

A noncondensable gas tube heat exchanger with variable spacing of flow stabilization devices

ActiveCN108204751BReduce spacingReduce vibrationStationary tubular conduit assembliesHeat transfer modificationPhase currentsNoise level

The invention provides a tube-shell heat exchanger. The tube-shell heat exchanger comprises a housing, wherein sealing heads are arranged at two ends of the housing; tube plates are arranged at positions where the sealing heads are connected to the housing; heat exchange tubes are connected to the tube plates at two ends; gas phase in gas-liquid two-phase current is insoluble or slightly-soluble gas, namely, gas cannot dissolve in liquid in the heat exchanging process. The tube-shell heat exchanger is characterized in that current stabilizers for absorbing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of current stabilizers are arranged in one heat exchange tube; the spacing between adjacent current stabilizers gradually increases in the flowing direction of the liquid in the heat exchange tubes until reaching some position, and then the spacing between the adjacent current stabilizers gradually decreases from the some position. According to the heatexchanger, the vibration of pipelines can be minimized based on the spacing change of the current stabilizers while the pipelines are subjected to gas-liquid two-phase flowing, and moreover, the noise level is decreased, and meanwhile, the flowing resistance is reduced.

Owner:山东卓奥环保科技股份有限公司

A steam heat exchanger with a steady flow structure

ActiveCN109737368BAvoid or reduce short circuitInhibit refluxSteam generation heating methodsFeed water supplyMechanical engineeringSheet structure

The invention provides a steam heat exchanger. The steam heat exchanger comprises a header and a steam pipe; steady flow devices are arranged inside the steam pipe and are each of a sheet structure; the sheet structures are arranged on the cross section of the steam pipe; the steady flow devices are composed of square through holes and right octagon through holes; the length of each side of the square through holes is equal to the length of each side of the right octagon through holes; the four sides of each square through hole are the sides of four different right octagon through holes; and the four spaced sides of each right octagon through hole are the sides of four different square through holes. Compared with a steady flow device in the prior art, the steam heat exchanger with the steady flow structures further improves the steady flow effect, enhances heat transfer and is easy to manufacture.

Owner:青岛鑫众合贸易有限公司

a steam boiler

ActiveCN109945148BAvoid or reduce short circuitInhibit refluxSteam generation using pressureSteam boilersEnhanced heat transferEngineering

Owner:广州融竹能源咨询有限公司

Vapor heat exchanger with pipeline communication

ActiveCN110067995AAvoid or reduce short circuitInhibit refluxSteam generation heating methodsBoiler water tubesEngineeringPressure balance

The invention provides a vapor heat exchanger. The vapor heat exchanger comprises a collecting box and steam tubes, wherein the steam tubes upwards extend from the collecting box; a steam inlet and acondensed water outlet are formed in the collecting box; steam enters the collecting box, and upwards flows from the collecting box to enter the steam tubes; the steam tubes perform heat exchange withoutside to form condensed water; condensed water returns into the collecting box under action of the gravity, and flows out from a water return hole in the lower part of the collecting box; a communication tube is arranged between at least two adjacent steam tubes of the multiple steam tubes; multiple communication tubes are arranged between adjacent steam tubes from the lower parts of the steamtubes to the upper parts of the steam tubes; and the diameters of the communication tubes are continuously increased from the lower parts of the steam tubes to the upper parts of the steam tubes. Along with upward flow of fluid, fluid continuously releases heat, and released heat in different heat collecting tubes becomes more and more uniform, and therefore, pressure balance can be guaranteed tobe reached as quickly as possible in a fluid flowing process.

Owner:YANTAI MOON HEAT EXCHANGE TECH

Optimum Design Method of Riser Tube Spacing

ActiveCN109882821BImprove heat transfer effectAvoid or reduce short circuitBoiler water tubesWater-tube boilersEngineeringOptimal design

The invention provides a design method of a steam boiler. The steam boiler comprises an upper boiler cylinder, a lower boiler cylinder, lifting pipes and falling pipes, wherein the lifting pipes and the falling pipes are connected between the upper boiler cylinder and the lower boiler cylinder. The design method comprises the steps that with the increase of the lifting pipe diameter, the lifting pipe spacing increases continuously. The change of a law is obtained by a large number of numerical simulation and experiments, and through the changes of the law, the heat transfer effect can be further improved.

Owner:江苏宝利晶石英材料股份有限公司

Steam heat exchanger with variable spacing of flow stabilization structures

InactiveCN110094710AReduce vibrationReduce noiseSteam generation heating methodsBoiler water tubesEngineeringMicro heat exchanger

The invention provides a steam heat exchanger. The steam heat exchanger includes a collecting box and steam pipes. Flow stabilization devices are arranged in the steam pipes. The multiple flow stabilization devices are arranged in the steam pipes. The spacing among the flow stabilization devices becomes smaller and smaller in a direction extending upward from inlets of the steam pipes. The steam heat exchanger of the invention further improves the flow stabilization effect and strengthens heat transfer through the spacing variation of the flow stabilization devices and is simple in manufacturing.

Owner:西安江凌环保科技有限公司

A heat exchanger system with multiple two-phase flow stabilization devices and its pipelines

ActiveCN106767088BImprove heat transfer performanceHas the effect of reducing vibration and noiseTubular elementsEngineeringNoise reduction

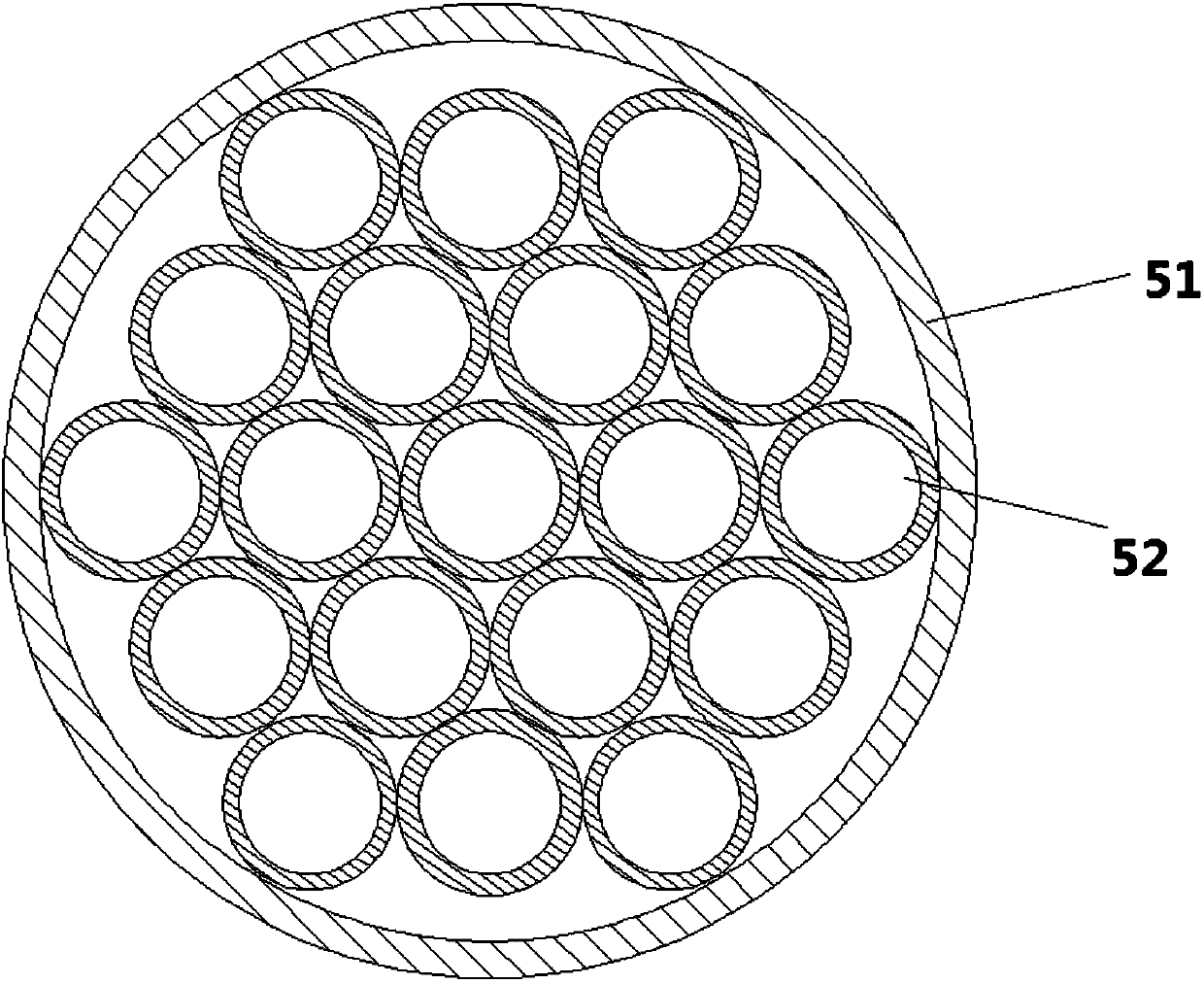

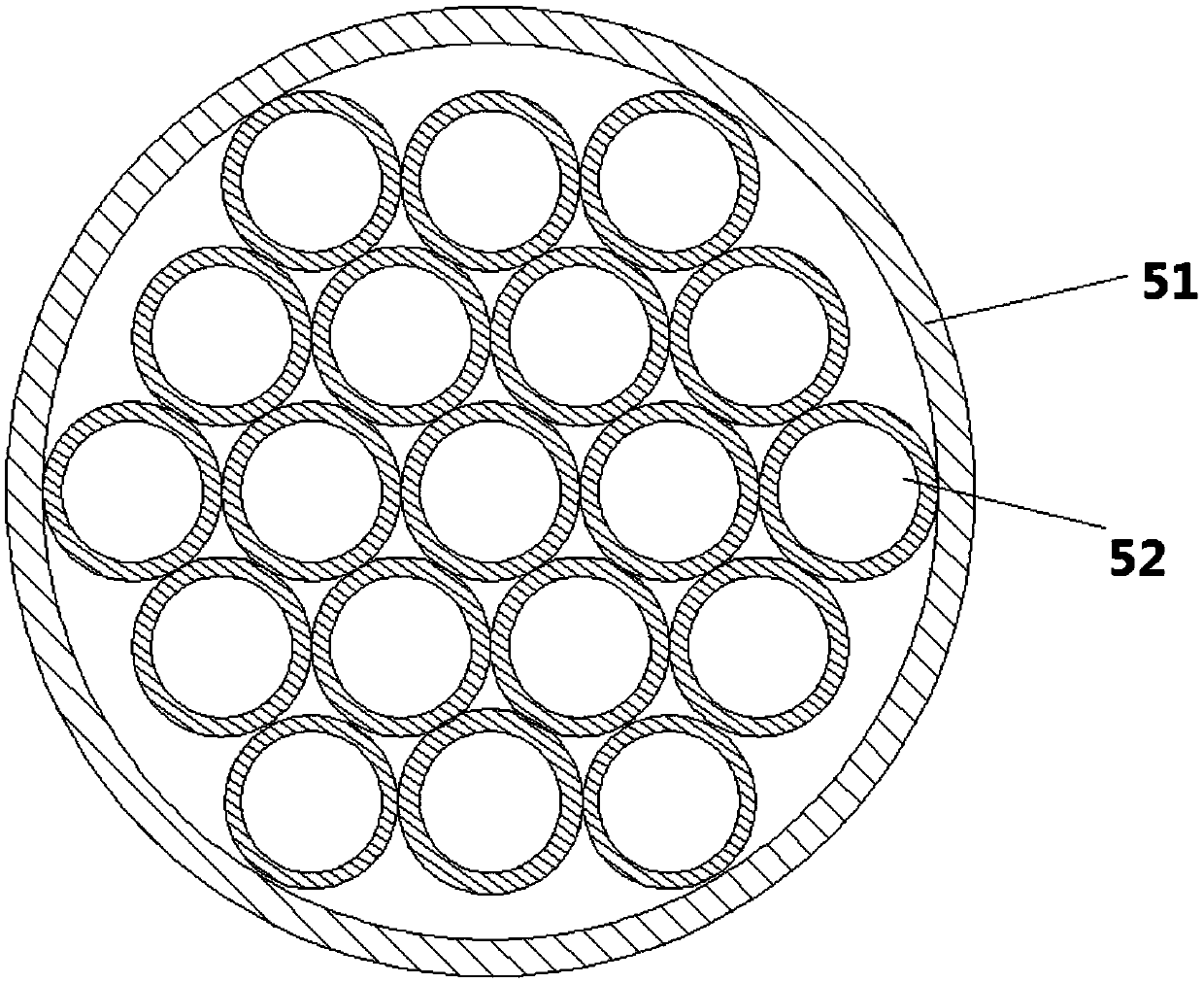

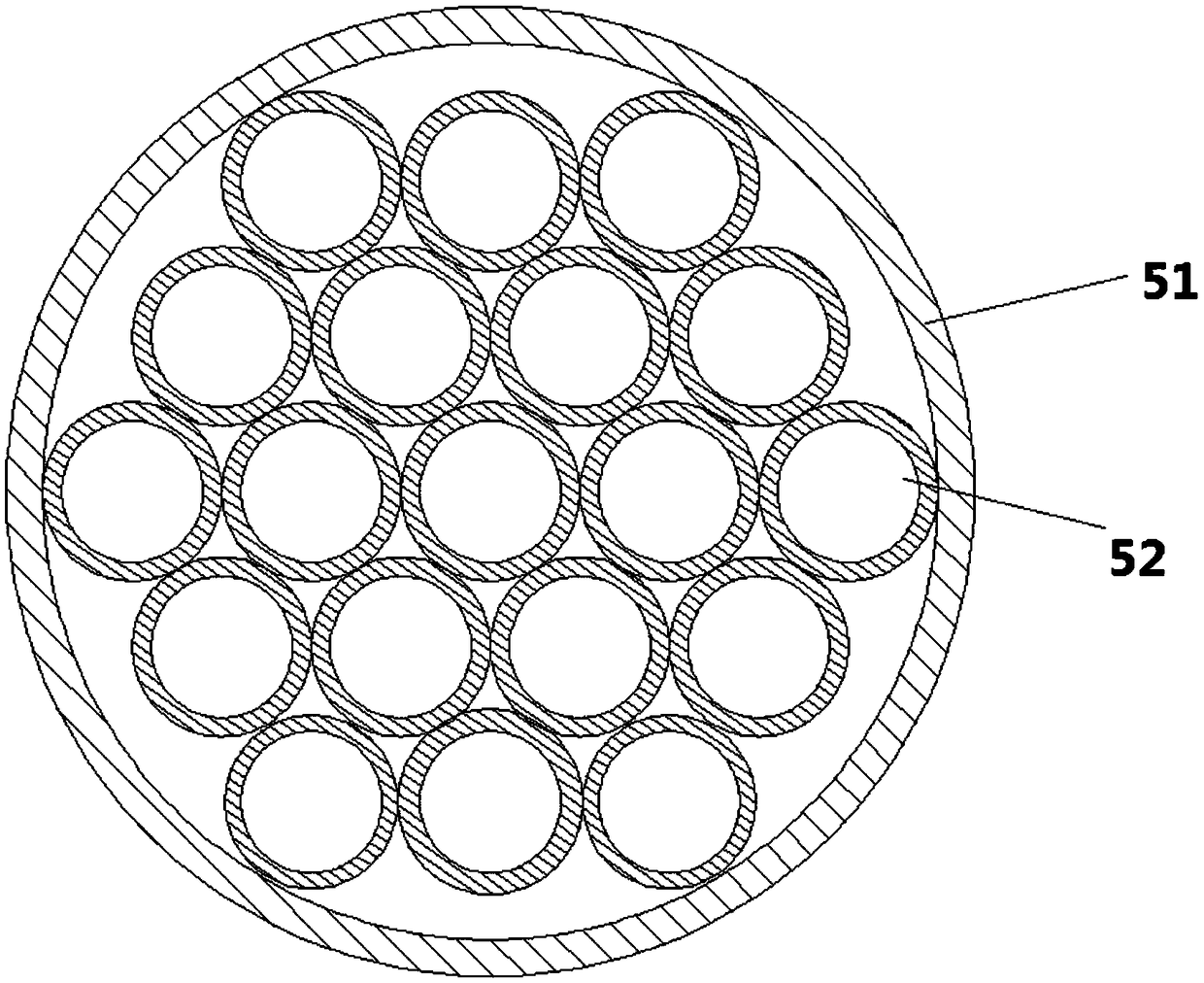

The invention provides a heat exchanger system provided with a plurality of two-phase flow stabilizing devices and a pipeline of the heat exchanger system. The two-phase flow stabilizing devices are arranged in the pipeline; each of the two-phase flow stabilizing devices comprises a core body; the core body can divide two phase flow runners in the pipeline into a plurality of small runners; and the two-phase flow stabilizing devices are continuously arranged or arranged at intervals. According to the invention, the two-phase flow stabilizing devices are continuously arranged or arranged at intervals, so that the liquid phase and the gaseous phase can be separated through a plurality of stages and steps, heat transfer can be further enhanced, and the effects of vibration and noise reduction are realized.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Steam heat exchanger capable of balancing pressure

ActiveCN110230806AAvoid or reduce short circuitInhibit refluxSteam generation heating methodsBoiler water tubesEngineeringPressure balance

The invention provides a steam heat exchanger. The steam heat exchanger comprises a collecting box and steam pipes, the steam pipes extends upwards from the collecting box, the collecting box is provided with a steam inlet and a condensed water outlet, the steam enters the collecting box, then flows upwards from the collecting box and enters the steam pipes, the steam pipes and the outside are subjected to heat exchange to form condensed water, the condensed water returns to the collecting box under the action of gravity, and then flows out from a water returning opening in the lower part of the collecting box; a plurality of steam pipes are arranged, a communicating pipe is arranged between at least two adjacent steam pipes, a plurality of communicating pipes are arranged between the adjacent steam pipes from the lower parts of the steam pipes to the upper parts of the steam pipes, and the distance between the adjacent communicating pipes is continuously reduced from the lower parts of the steam pipes to the upper parts of the steam pipes. Due to the fact that along with flowing upward of the fluid, the fluid continuously releases heat, along with continuously heat releasing of the fluid, heat releasing in different heat collecting pipes gets more and more ununiformly, by virtue of above arrangement, the pressure balance can be achieved as soon as possible in the fluid flowingprocess.

Owner:甘肃国晟堂药业有限公司

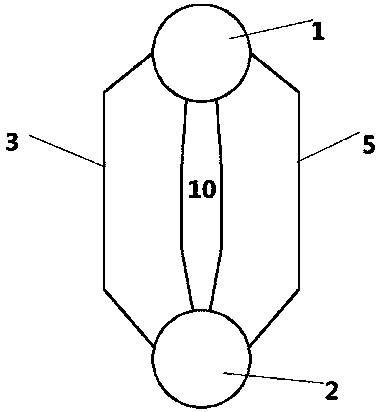

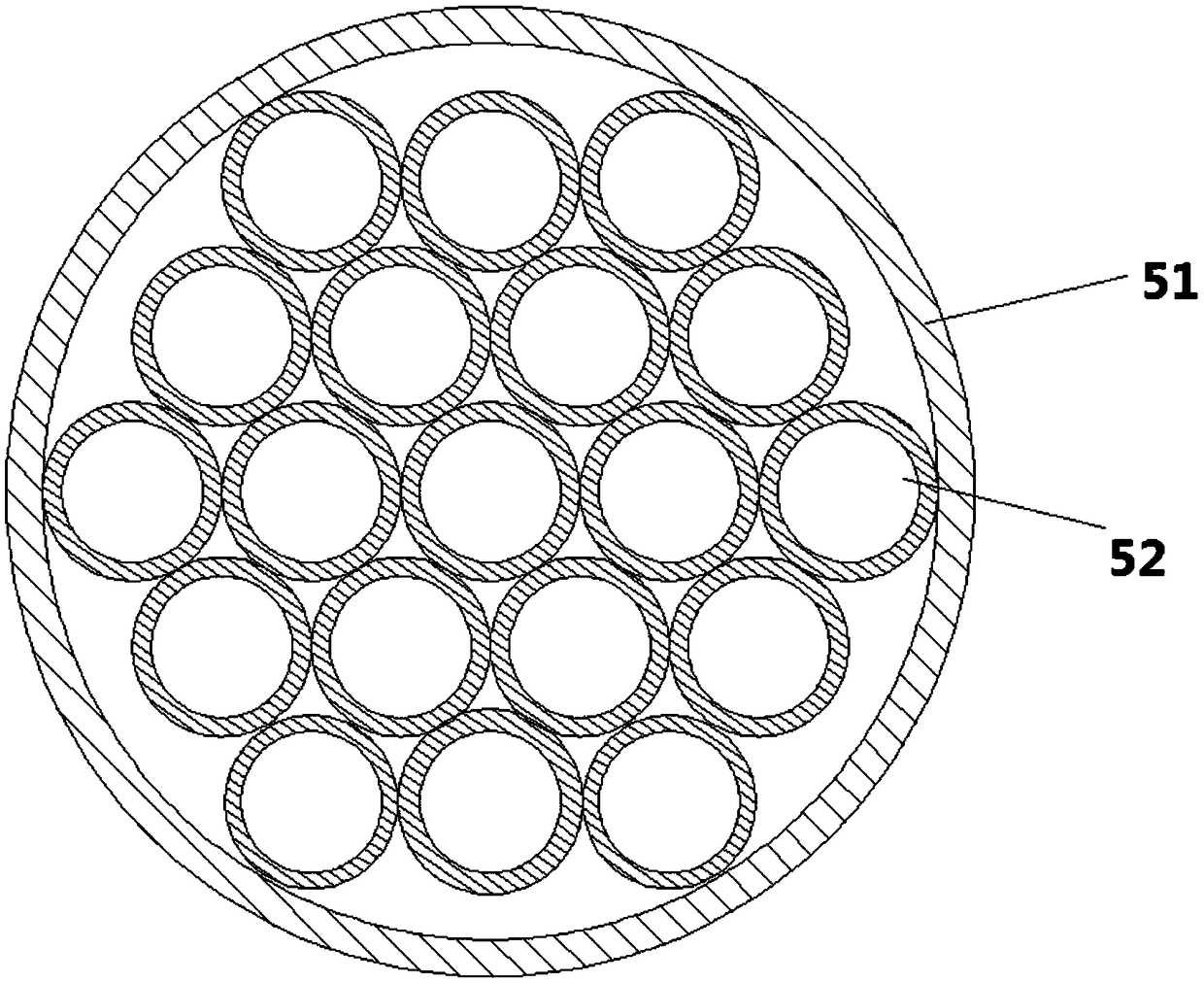

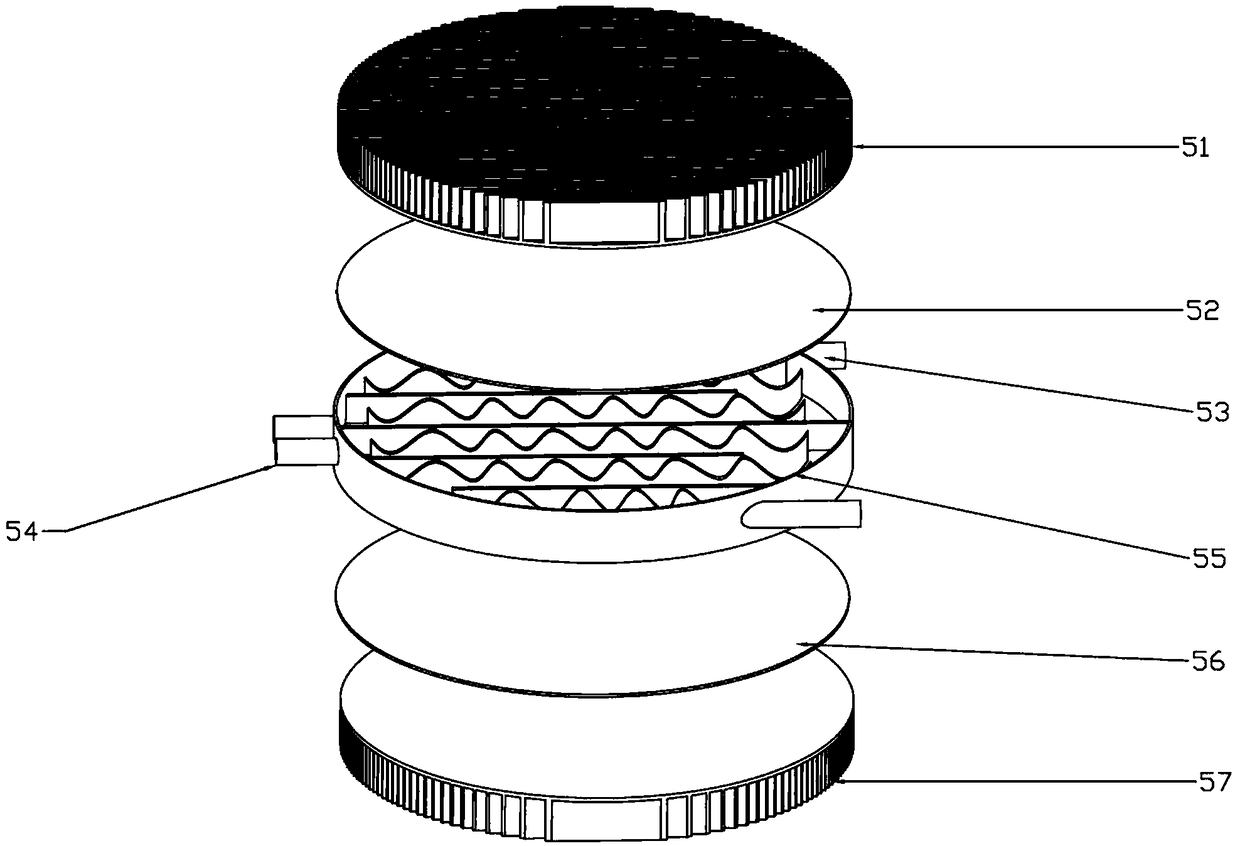

A shell-and-tube heat exchanger of a multi-tube type steady flow device with condensable vapor phase

InactiveCN107869924BInhibit refluxSpeed up the flowStationary tubular conduit assembliesTubular elementsVapor liquidShell and tube heat exchanger

The invention provides a gas-liquid two-phase flow multi-tube shell-and-tube heat exchanger, which includes a shell, and the two ends of the shell are respectively provided with heads, and the connection position between the head and the shell is set with a tube plate. The heat exchange tubes are connected to the tube sheets at both ends, and the vapor phase in the vapor-liquid two-phase flow can be condensed into a liquid phase during the heat exchange process. A body and a shell, the core is arranged in the shell, the shell is connected and fixed with the inner wall of the heat exchange tube, and the core is composed of several adjacent tubes. The invention provides a heat exchanger of a flow stabilizing device with a new structure, which can enhance heat transfer, weaken the vibration of the pipeline and reduce the noise level when there is a vapor-liquid two-phase flow in the pipeline.

Owner:SHANDONG UNIV

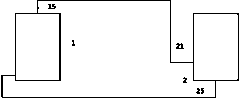

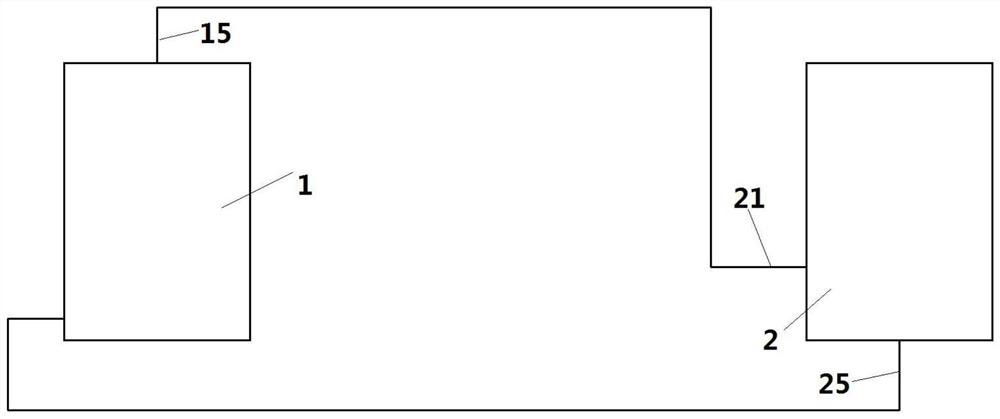

Steam generation system intelligently controlled according to inlet steam pressure

InactiveCN111911902AEnsure safetyGuaranteed to meet the heat transfer requirementsSteam boilersData connectionSteam pressure

The invention provides an evaporator system. The evaporator system comprises an evaporator and steam utilization equipment; steam generated by heating in the evaporator enters the steam utilization equipment through a steam inlet pipe, is subjected to sufficient heat exchange and utilization in the steam utilization equipment, and then is recycled and mixed into the evaporator for heating; the evaporator comprises a steam chamber, an electric heating device is arranged in the steam chamber, a steam outlet pipeline is arranged at the upper part of the steam chamber, and a water inlet pipeline is arranged in the steam chamber; a pressure sensor is arranged on the steam inlet pipe of the steam utilization equipment and is used for measuring the pressure in the steam inlet pipe; and the pressure sensor and the electric heating device are in data connection with a controller, and the controller automatically controls the heating power of the electric heating device according to the pressuremeasured by the pressure sensor. According to the steam generation system intelligently controlled according to inlet steam pressure, by means of the arrangement, the heating power can be adjusted according to the pressure of the steam inlet pipe 21, so that it is guaranteed that the heat exchange amount of the steam utilization equipment meets the requirement, and meanwhile the safety of the evaporator is guaranteed under the condition that steam output is maximized.

Owner:QINGDAO XINZHONGHE TRADE CO LTD

A Heat Exchanger for Condensable Gas with Increased Spacing of Stabilizing Devices

InactiveCN107894178BReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationGas phaseNoise level

Owner:SHANDONG UNIV

A non-condensable gas tube heat exchanger with variable length of flow stabilization device

InactiveCN107869927BReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationGas phaseNoise level

The present invention provides a gas-liquid two-phase flow multi-tube shell-and-tube heat exchanger, which includes a shell, and the two ends of the shell are respectively provided with heads, and the connection position between the head and the shell is set with a tube plate. The heat exchange tube is connected to the tube sheets at both ends. The gas phase in the vapor-liquid two-phase flow is an insoluble or insoluble gas, that is, the gas will not dissolve in the liquid during the heat exchange process. It is characterized in that the heat exchange tube is set for reducing A stabilizing device for vibration and noise reduction. Multiple stabilizing devices are installed in the same heat exchange tube. Along the flow direction of the fluid in the heat exchange tube, the length of the stabilizing device first gradually decreases to a certain position, and then from From a position, the length of the flow stabilizing device increases gradually. The invention provides a method for reducing the vibration of the pipeline to the greatest extent, lowering the noise level and reducing the flow resistance at the same time when the gas-liquid two-phase flow exists in the pipeline through the length change of the flow stabilizing device.

Owner:SHANDONG UNIV

Steam generation system intelligently controlled according to heating power

The invention provides an evaporator system. The evaporator system comprises an evaporator and a steam utilization device, steam generated by heating in the evaporator enters the steam utilization device through a steam inlet pipe, and after sufficient heat exchange and utilization in the steam utilization device, the steam is circularly mixed into the evaporator to be heated; the evaporator comprises a steam chamber, and an electric heating device is arranged in the steam chamber; and a water level sensor is arranged in the steam chamber, the water level sensor and an electric heater are in data connection with a controller, and the controller automatically controls the heating power of the electric heater according to the measured water level in the steam chamber. By means of the arrangement, on one hand, dry burning of the electric heating device, damage to the electric heating device and safety accidents caused by too low water level are avoided, and on the other hand, too low steam output rate caused by too large water amount in the steam chamber due to too high water level is avoided.

Owner:青岛鑫众合贸易有限公司

Design Method of Steam Boiler with Different Riser and Downpipe Diameters

InactiveCN109882822BSpeed up the flowIncrease resistanceBoiler water tubesWater-tube boilersThermodynamicsEngineering

The invention provides a designing method of a steam boiler and provides a designing method for a steam boiler with a flow stabilizing device of a novel structure. The steam boiler comprises an upperboiler barrel, a lower boiler barrel, an ascending pipe and a descending pipe, wherein the ascending pipe and the descending pipe are connected between the upper boiler barrel and the lower boiler barrel. The steam boiler is characterized in that the pipe diameter of the ascending pipe is larger than that of the descending pipe. By arranging the pipe diameter of the ascending pipe to be greater than that of the descending pipe, resistance of the descending pipe is mainly increased, the resistance of the ascending pipe is reduced, steam flows in an evaporation portion more easily, and a hoop pipeline better forms circulation.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST

A steam heat exchanger for drying medicinal materials

ActiveCN110230806BUniform pressureIncrease the heat exchange areaSteam generation heating methodsBoiler water tubesMedicinal herbsPetroleum engineering

The invention provides a steam heat exchanger. The steam heat exchanger comprises a collecting box and steam pipes, the steam pipes extends upwards from the collecting box, the collecting box is provided with a steam inlet and a condensed water outlet, the steam enters the collecting box, then flows upwards from the collecting box and enters the steam pipes, the steam pipes and the outside are subjected to heat exchange to form condensed water, the condensed water returns to the collecting box under the action of gravity, and then flows out from a water returning opening in the lower part of the collecting box; a plurality of steam pipes are arranged, a communicating pipe is arranged between at least two adjacent steam pipes, a plurality of communicating pipes are arranged between the adjacent steam pipes from the lower parts of the steam pipes to the upper parts of the steam pipes, and the distance between the adjacent communicating pipes is continuously reduced from the lower parts of the steam pipes to the upper parts of the steam pipes. Due to the fact that along with flowing upward of the fluid, the fluid continuously releases heat, along with continuously heat releasing of the fluid, heat releasing in different heat collecting pipes gets more and more ununiformly, by virtue of above arrangement, the pressure balance can be achieved as soon as possible in the fluid flowingprocess.

Owner:甘肃国晟堂药业有限公司

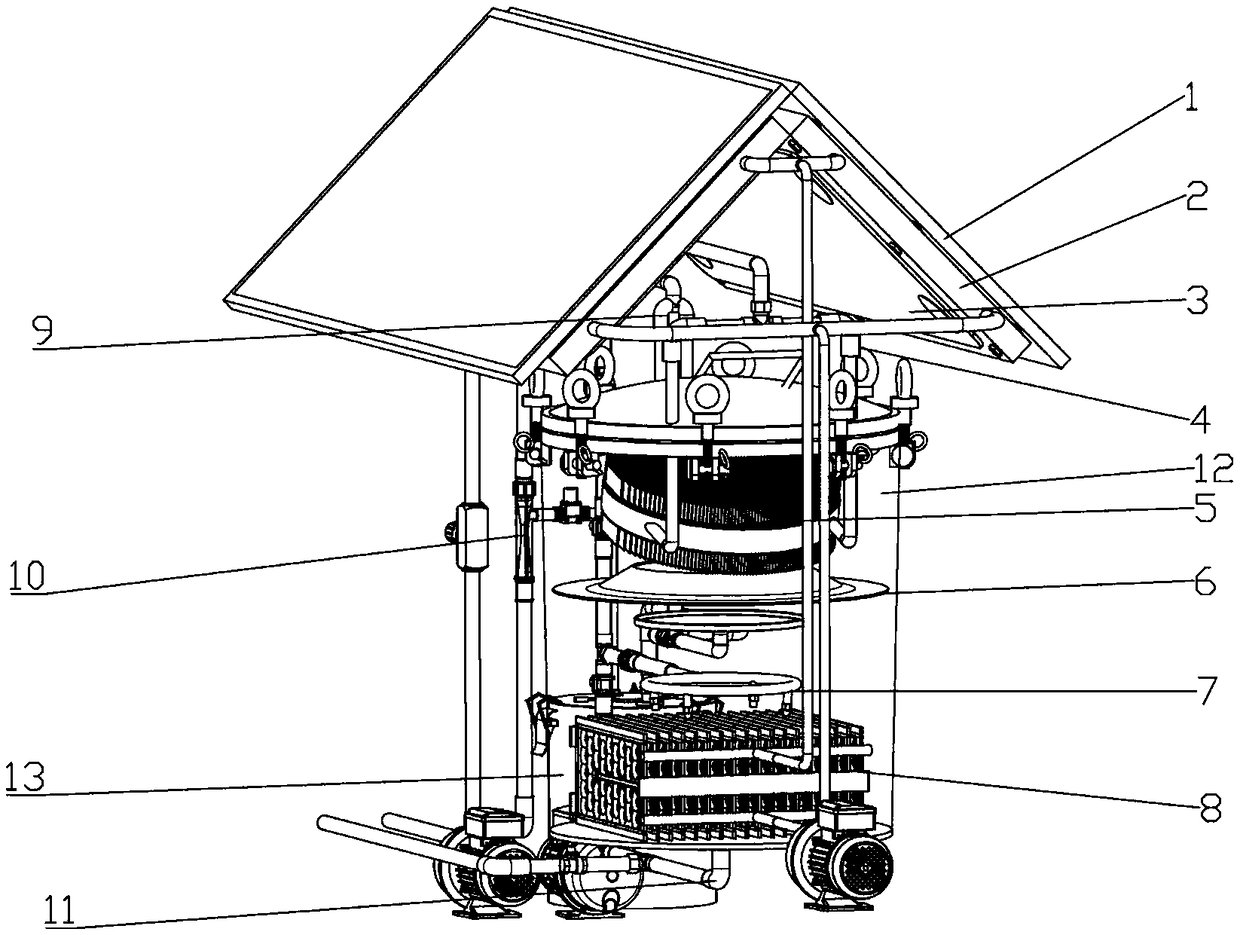

Circulatory spraying heat exchange system

ActiveCN109437354AImprove utilizationRealize the collectionGeneral water supply conservationSeawater treatmentSpray nozzleFresh water

The invention provides a circulatory spraying heat exchange system. The circulatory spraying heat exchange system comprises a tank; a circulatory spray pump, a spray nozzle and a circulating pipe arearranged inside the tank, and the spray nozzle is arranged on the upper portion of an evaporator; the circulatory spray pump can pump seawater into the spray nozzle, and then the spray nozzle sprays the seawater onto the evaporator. The circulatory spraying heat exchange system can absorb heat of the evaporator through the unevaporated seawater to achieve conversion from seawater to fresh water tothe maximum degree, thereby maximizing utilization effects.

Owner:SHANDONG UNIV

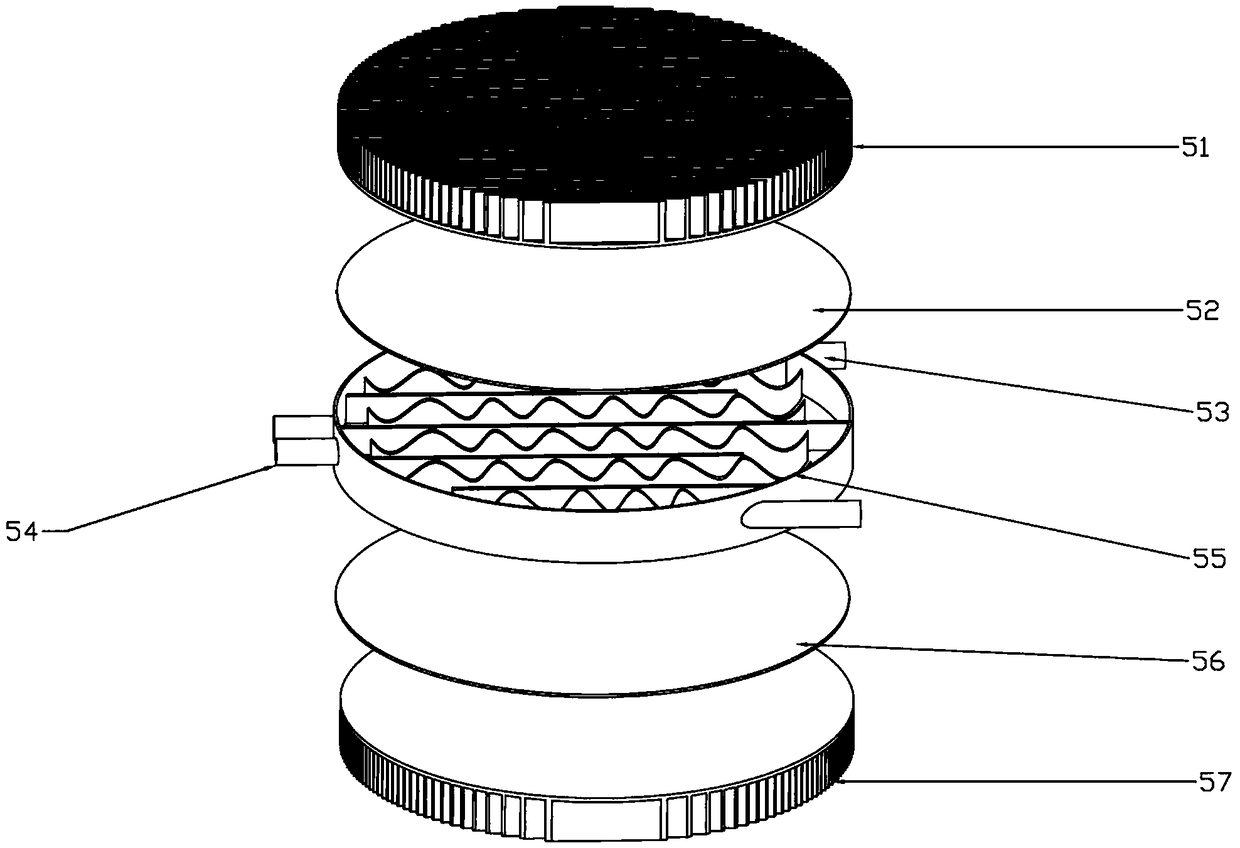

A two-phase flow shell-and-tube heat exchanger and its stabilizing device

ActiveCN107062952BSpeed up the flowInhibit refluxSafety devices for heat exchange apparatusHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

The invention provides a two-phase flow shell and tube heat exchanger and a stabilizing device thereof. The two-phase flow shell and tube heat exchanger comprises the sleeve type two-phase flow stabilizing device arranged on a fluid inlet pipe and / or a fluid outlet pipe of the heat exchanger. The two-phase flow stabilizing device comprises a core body, the core body comprises a plurality of concentric pipes and a plurality of fins, and the fins are connected with the adjacent concentric pipes. According to the two-phase flow shell and tube heat exchanger and the stabilizing device thereof, the passive two-phase flow stabilizing device with vibration and noise reduction functions can divide two-phase fluid into a liquid phase and a gas phase under the condition of not relying on external power or power sources, the liquid phase is divided into small liquid balls, the gas phase is divided into small bubbles, liquid phase back flowing is prohibited, smooth flowing of the gas phase is facilitated, the function of stabilizing the flow rate is achieved, and the vibration and noise reduction effects are achieved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com