Demodulation method of multi-core fiber Bragg grating curvature sensor

A technology of curvature sensor and multi-core optical fiber, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problems of high demodulation cost and complex demodulation methods of spectrum analyzers, and achieve demodulation mode Simplification, reduction of demodulation cost, and strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For simplicity, some technical features known to those skilled in the art are omitted from the following description.

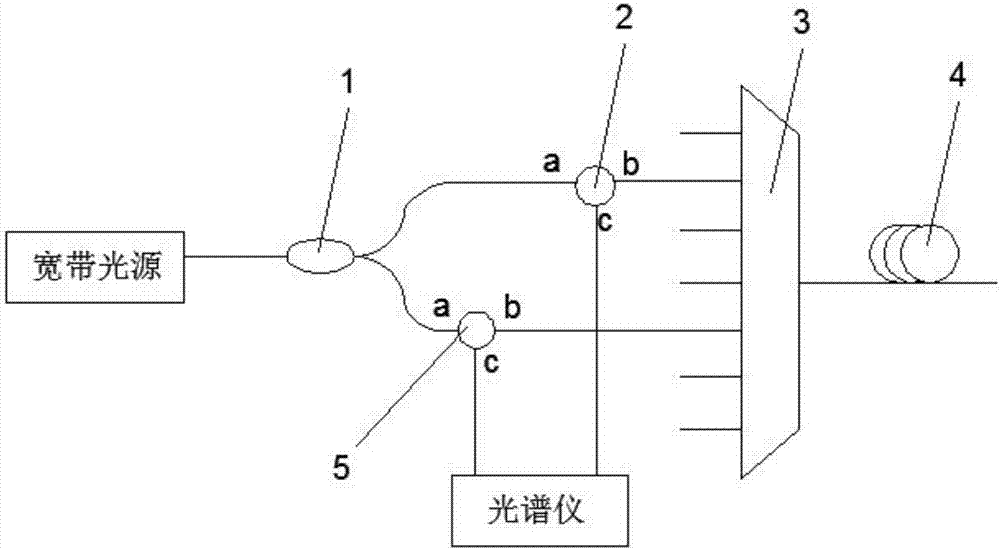

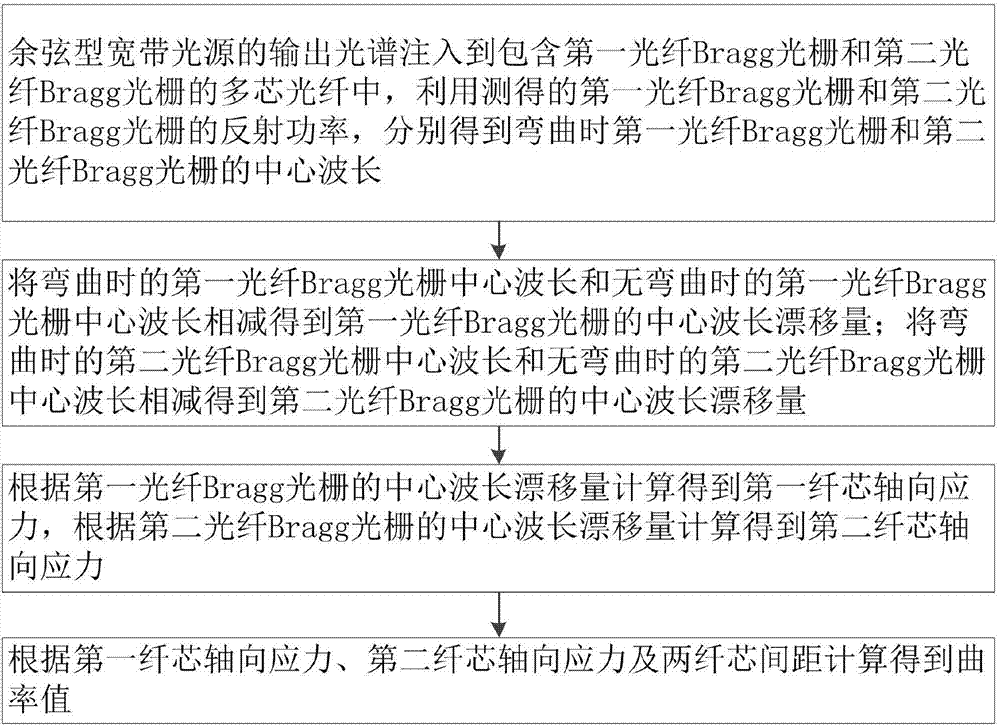

[0017] A demodulation method of multi-core fiber Bragg grating curvature sensor, using cosine-type broadband light source to replace figure 1 In the broadband light source, the optical power meter, photodetector and other instruments that can detect the reflected power are used to replace the spectrometer to realize the demodulation of the central wavelength of the fiber Bragg grating, such as figure 2 shown, including the following steps:

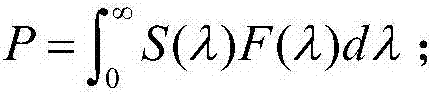

[0018] S1, the output spectrum of the cosine-type broadband light source is injected into the multi-core optical fiber comprising the first fiber Bragg grating and the second fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com