Testing method of soil organic matter

A measurement method and organic matter technology, applied in chemical analysis by titration method, measurement device, preparation of test samples, etc., can solve the problems of small measurement results, damage to the tester, easy evaporation, etc., and reduce the damage caused by the measurement results The effect of the impact, the safety of the measurement process, and the accuracy of the experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

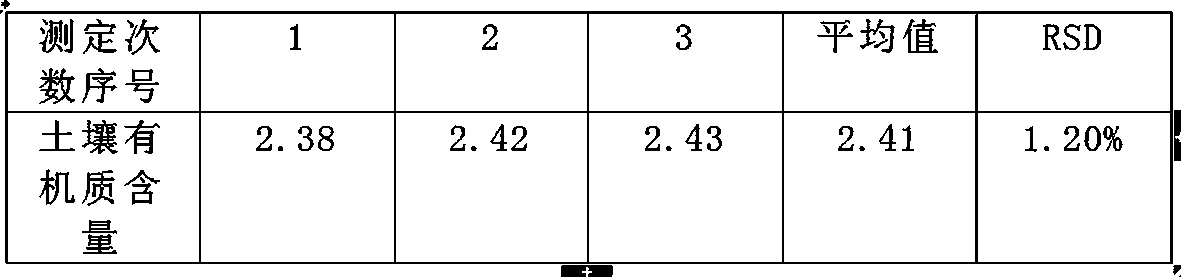

[0023] Determination of soil organic matter in the square in front of the South Railway Station of a certain city.

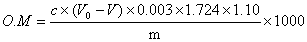

[0024] The soil in the 20cm-30cm soil layer below the surface was collected in the square in front of the station, and after being air-dried for 7-10 days, the soil samples were passed through a 0.25mm aperture sieve. Accurately weigh 0.3g of the air-dried sample that passed through a 0.25mm aperture sieve, put it into a hard test tube, then accurately add 10.00mL0.4mol / L potassium dichromate-sulfuric acid solution, shake well and insert a glass funnel into the test tube mouth . Insert the test tube into the heat-collecting constant temperature magnetic stirring reaction bath pot of HWCL-3 produced by Zhengzhou Great Wall Technology Industry and Trade Co., Ltd. After the power is turned on, when the temperature of the oil bath rises to 185°C, immediately cut off the power and stop the oil bath At this time, put the sample again, the liquid level in the sample t...

Embodiment 2

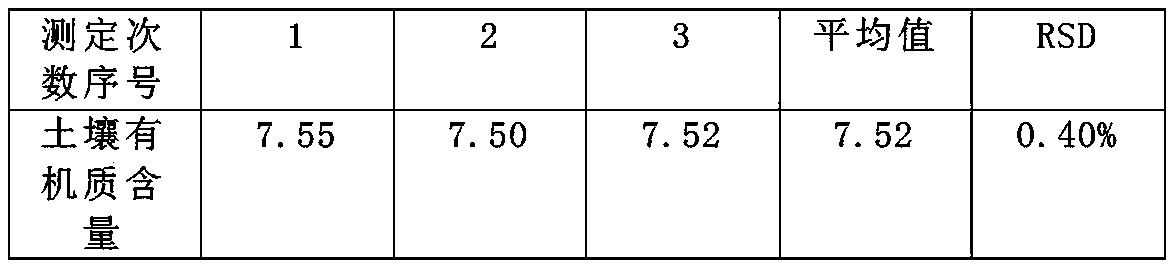

[0030] Determination of soil organic matter in a certain urban area of a certain city

[0031] The soil in the 20cm-30cm soil layer below the surface was collected at this place, and after being air-dried for 7-10 days, the soil samples were passed through a 0.25mm aperture sieve. Accurately weigh 0.5g of the air-dried sample that passed through a 0.25mm aperture sieve, put it into a hard test tube, then accurately add 10.00mL0.4mol / L potassium dichromate-sulfuric acid solution, shake well and insert a glass funnel into the test tube mouth . Insert the test tube into the heat-collecting constant temperature magnetic stirring reaction bath pot of HWCL-3 produced by Zhengzhou Great Wall Technology Industry and Trade Co., Ltd. After the power is turned on, when the temperature of the oil bath rises to 185°C, immediately cut off the power and stop the oil bath At this time, put the sample again, the liquid level in the sample tube can still be lower than the oil level, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com