Method for measuring musk xylene and sesamol in tobacco additive

A technology of cigarette additive and xylene musk, which is used in measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

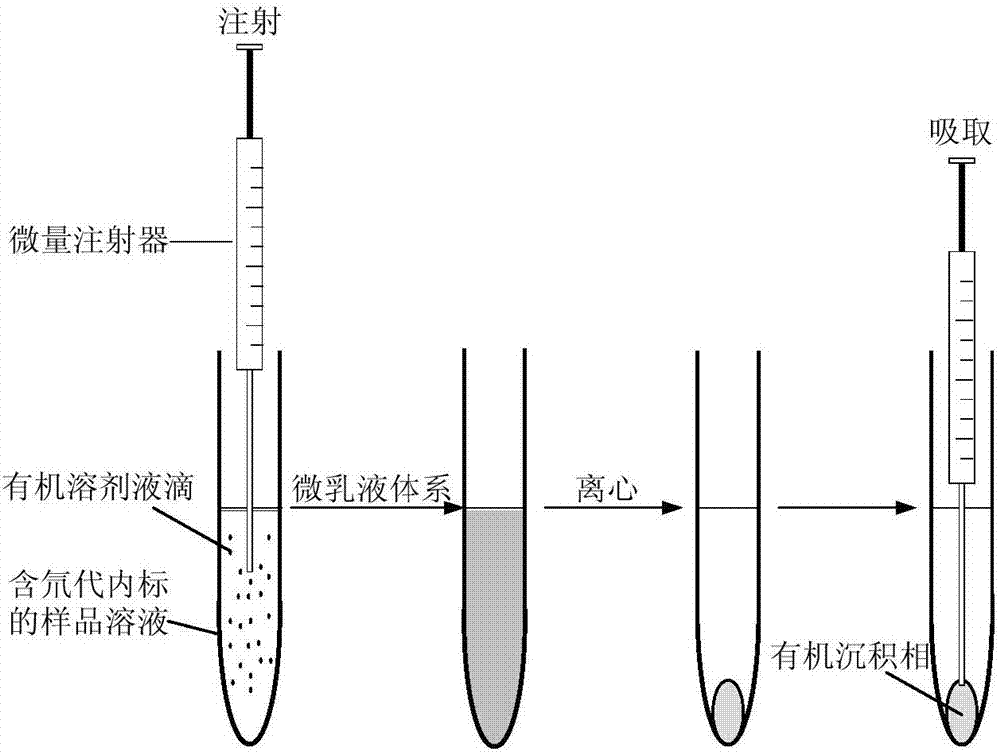

Method used

Image

Examples

Embodiment 1

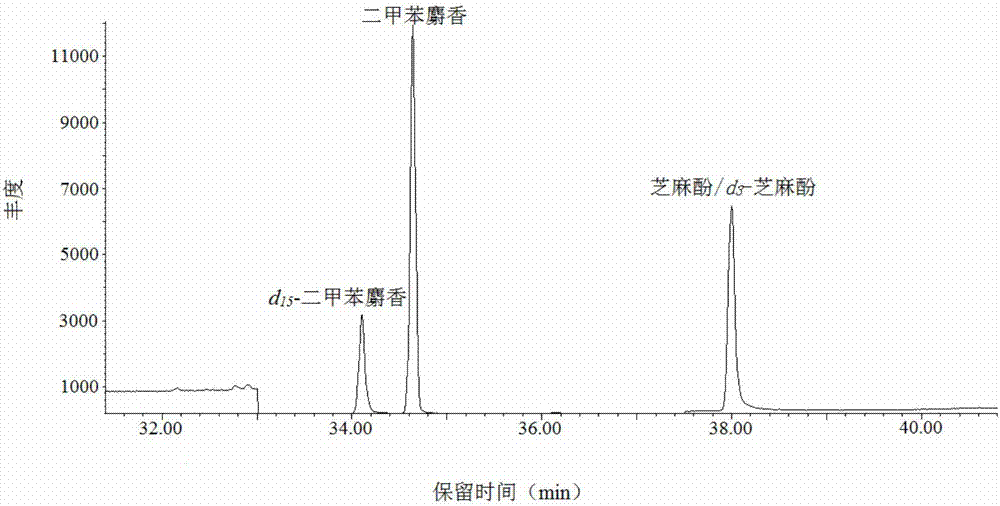

[0077] 1. Preparation of standard solution

[0078] Weigh the standard products of musk xylene and sesamol respectively, add absolute ethanol to constant volume, and make a mixed standard stock solution. The concentrations of musk xylene and sesamol in the mixed standard stock solution are both 1-100 μg / mL. Simultaneously, pipette the isotopes of musk xylene and the isotope of sesamol of a certain volume respectively, specifically deuterated musk xylene and deuterated sesamol, add absolute ethanol to constant volume, be made into internal standard solution, in the internal standard solution, two The concentrations of isotopes of toluene musk and sesamol are 10-1000 μg / mL.

[0079] Accurately pipette different volumes of mixed standard stock solutions, place them in multiple 100mL volumetric flasks, then accurately add a certain volume of internal standard solution, and dilute with absolute ethanol to prepare a series of mixed standard solutions. The concentration of the prep...

Embodiment 2

[0091] 1. Preparation of standard solution

[0092] Weigh the standard products of musk xylene and sesamol respectively, add absolute ethanol to constant volume, and make a mixed standard stock solution. The concentration of xylene musk and sesamol in the mixed standard stock solution was 10 μg / mL. Simultaneously, pipette the isotopes of musk xylene and the isotope of sesamol of a certain volume respectively, specifically deuterated musk xylene and deuterated sesamol, add absolute ethanol to constant volume, be made into internal standard solution, in the internal standard solution, two The concentration of the isotope of toluene musk and the isotope of sesamol was 100 μg / mL.

[0093] Accurately pipette different volumes of mixed standard stock solutions, place them in five 100mL volumetric flasks, then accurately add a certain volume of internal standard solution, and dilute with absolute ethanol to prepare a series of mixed standard solutions. The concentrations of the pre...

Embodiment 3

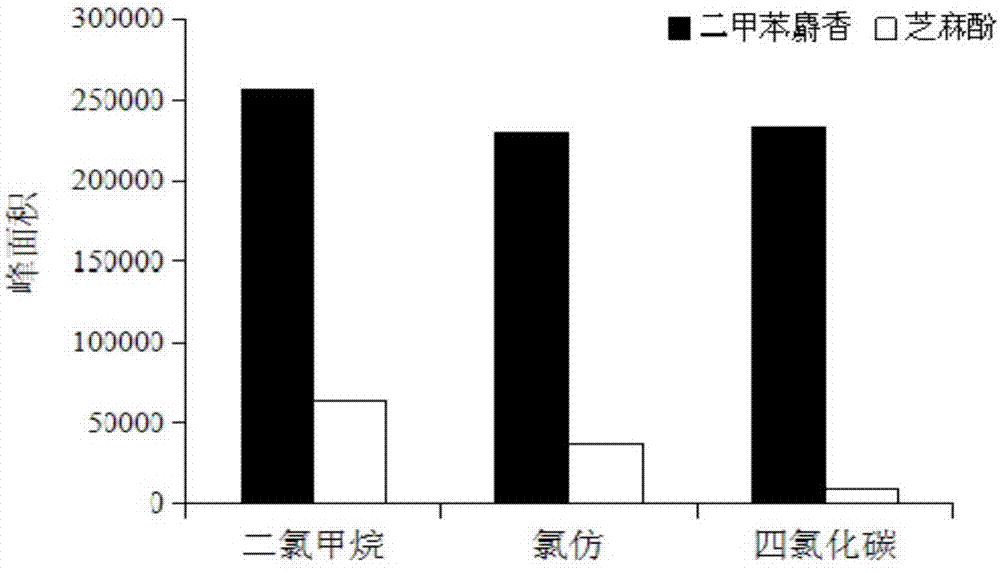

[0108] According to the method steps of measuring the content of xylene musk and sesamol in the sample of tobacco additives in Example 2, three kinds of solvents of dichloromethane, chloroform and carbon tetrachloride are respectively selected as the extraction agent to carry out sample pretreatment, and the measurement results are shown in image 3 . Depend on image 3 It can be seen that dichloromethane, chloroform and carbon tetrachloride can be used as extraction agents for sample pretreatment, but dichloromethane has the best extraction effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com