Breaker test line hitching rod

A technology of testing wires and hooking rods, which is applied in the direction of instruments, measuring devices, and measuring electrical variables. It can solve the problems of unsafe and inconvenient mounting of testing wires, and achieve saving of working time, convenient disassembly and assembly, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

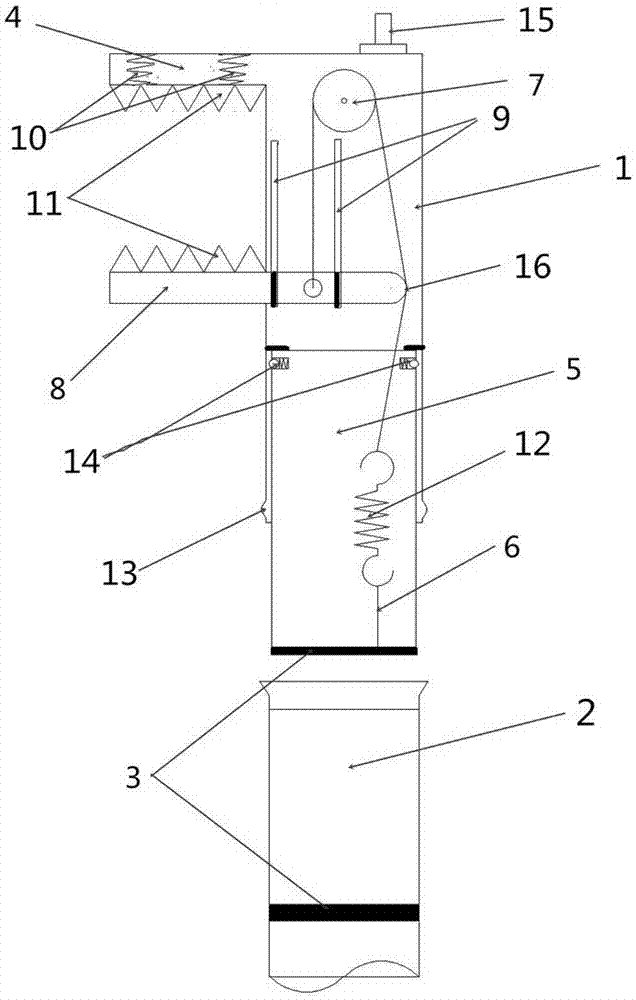

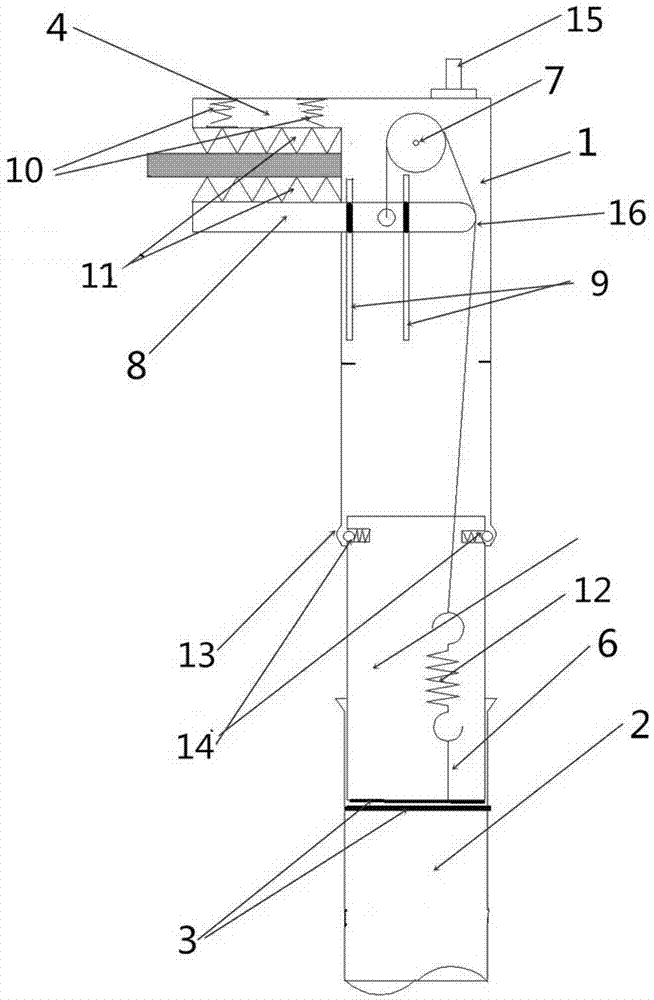

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] As shown in 1, the connecting rod of the circuit breaker test line includes a chuck 1 and an operating rod 2, and the chuck 1 is inserted into the socket on the upper part of the operating rod; the chuck includes a fixed chuck 4, The movable chuck 8 and the movable guide rod 5, the fixed chuck 4 is a 7-type overall, the bottom of which is connected with the movable guide rod, the movable chuck 8 is installed in the middle of the fixed chuck and arranged parallel to the top of the fixed chuck, and the fixed chuck A fixed pulley 7 is installed on the head, and one end of the transmission wire rope 6 is connected on the movable chuck, and the other end walks around the fixed pulley and the friction contact surface 16 and is connected on the movable guide rod. Terminal post 15 is arranged on the top of fixed clip.

[0021] A strong magnetic sheet 3 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com