Remote control method for straw fermentation biogas production

A remote control and biogas technology, applied in the direction of electrical program control, program control, general control system, etc., can solve the problems of inability to realize real-time monitoring of production equipment operation status, inability to report remotely, cumbersome configuration procedures, etc., and achieve automatic control effect Good, saving control cables and control points, saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solution of the present invention will be further described below in conjunction with the drawings.

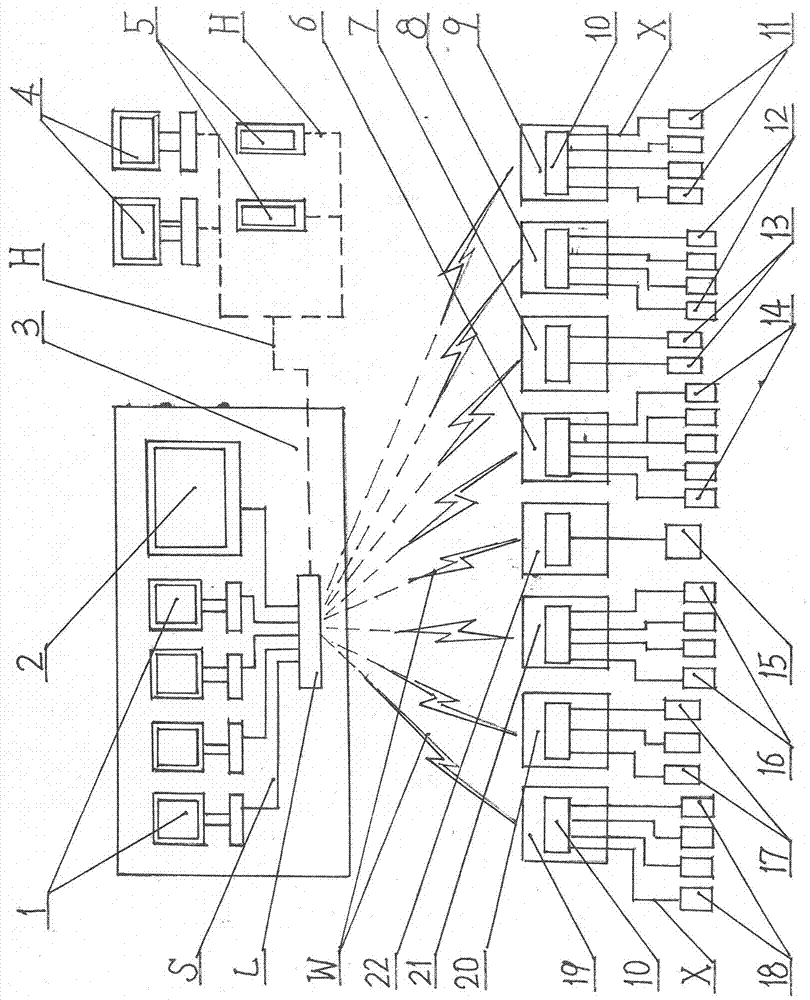

[0010] Refer to figure 1 , The present invention includes a control center 3 composed of a field control computer 1, a display 2, and a router L. The remote control computer 4 and the mobile phone 5 are remotely viewed through Internet H. The control center 3 communicates with various control terminals and monitoring terminals through a wireless remote control network W , Each control terminal and monitoring terminal are respectively connected to the equipment on the biogas production line and the control point and monitoring point on the pipeline through the signal line X. Each control terminal and monitoring terminal are respectively equipped with an integrated circuit 10, and the wireless remote control network W and router L Connect with the field control computer 1, and input the collected feedback signals into the field control computer 1. The field con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com