A Calculation Method for Hot Spot Temperature of Separate Cooling Transformer in Underground Substation

A technology of underground substation and hot spot temperature, which is applied in calculation, instrumentation, complex mathematical operations, etc., can solve problems such as temperature calculation of split transformers, and achieve the effect of promoting in-depth application and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

[0031] The method for calculating the hot spot temperature of a split-type cooling transformer includes the following steps:

[0032] (1) Obtain the factory parameters of the split cooling system transformer that is put into operation in the transformer factory and used for experimental research.

[0033] (2) Carry out the no-load test and short-circuit test of the transformer, and test the no-load loss and load loss of the split transformer for subsequent thermal circuit calculations.

[0034] (3) Through the temperature rise test of the transformer, the calculation of the thermal resistance of the important unknown parameter of the model, the calculation parameter of the transformer oil, is realized.

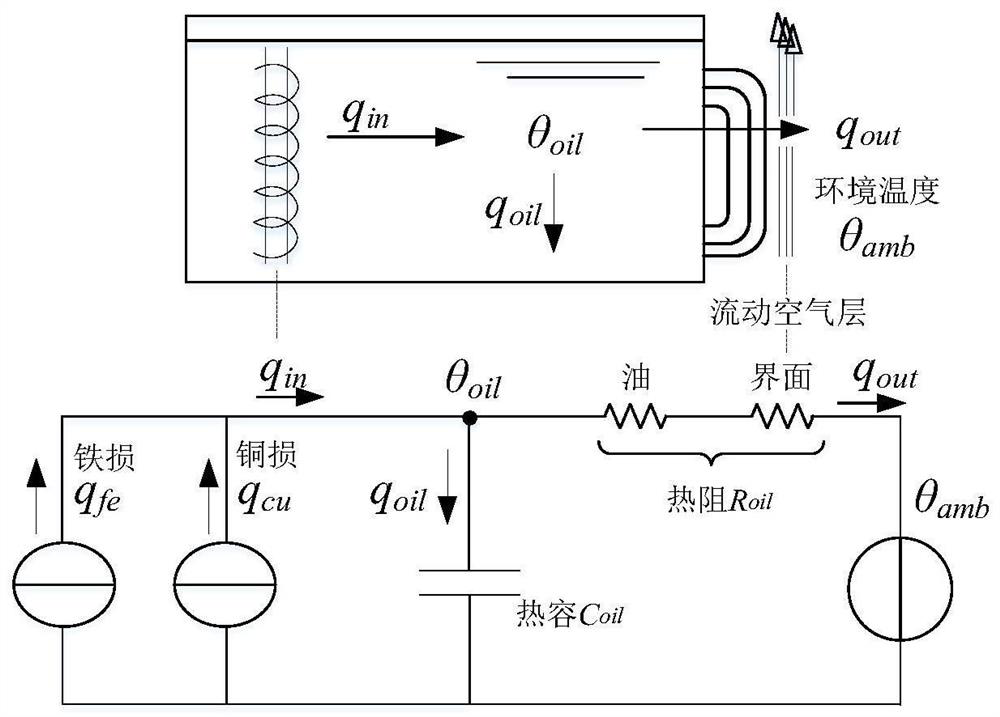

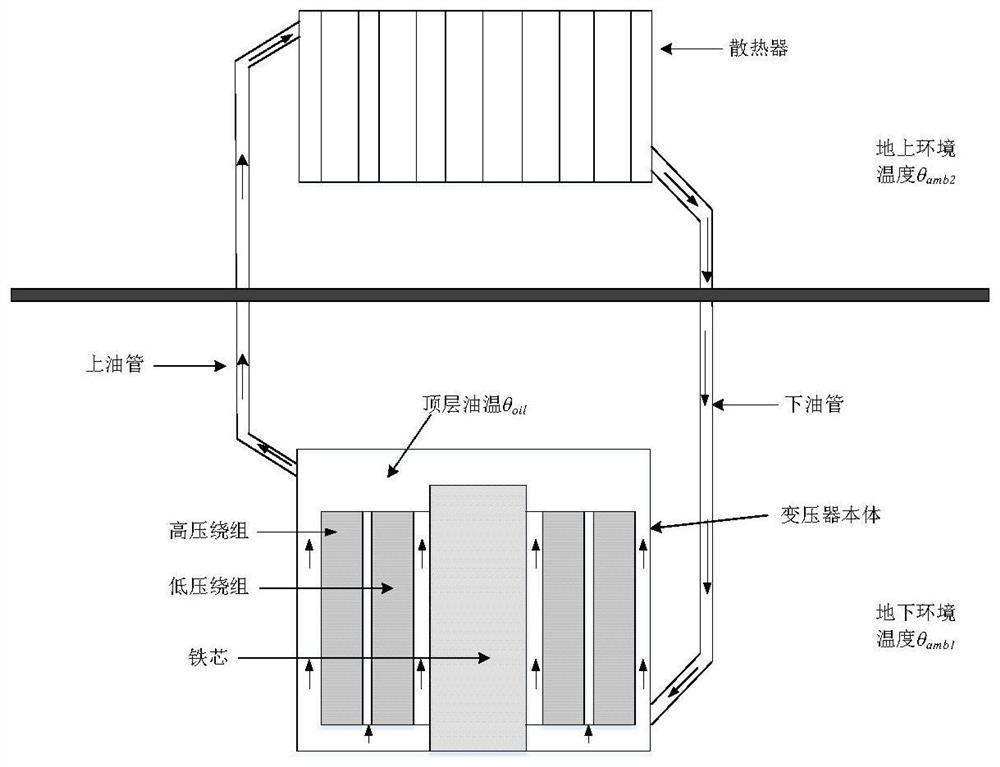

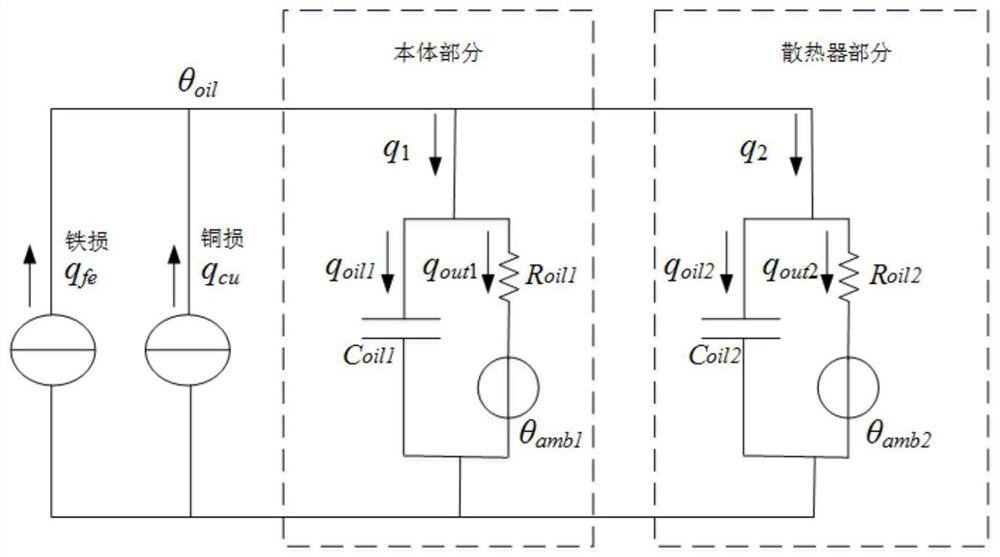

[0035] (4) According to the swift thermal circuit model of the transformer, the thermal circuit calculation model diagram of the split tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com