Luminous drive system

A luminous drive and column drive technology, applied in instruments, static indicators, etc., can solve the problems of complex construction thickness and high cost of LED display, and achieve the effect of reducing construction procedures, reducing space occupied, and simple construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

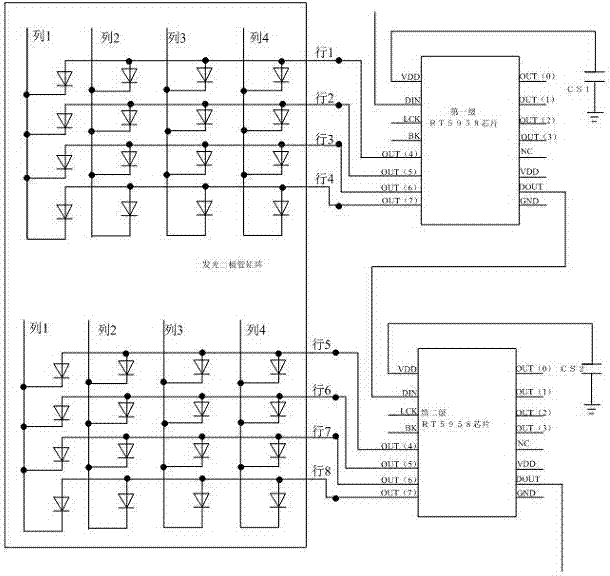

[0017] Such as figure 1 , figure 1 Only part of the area of the LED matrix and two RT5958 chips are shown in the figure. In reality, the LED matrix has 60 columns and 30 rows, but only 4 columns and 8 rows are shown in the figure, but in reality there are 4 RT5958 chips, and only 2 RT5958 chips are shown in the figure, but the principle has been clearly expressed , the PX4 model is just a naming method, mainly named according to the size of the gap between the lamp beads.

[0018] Specifically, a PX4 type light-emitting drive system includes a light-emitting diode matrix, the light-emitting diode matrix is composed of 60 columns and 30 rows of lamp beads arranged in a rectangular array, and the light-emitting diode matrix has 30 row input terminals and 60 column input terminals, the size of which is 256mm*128mm, also includes a row driving device, the row driving device includes 4 RT5958 chips for driving the LED matrix, and the RT5958 chips have decoding and driving fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com