Winding method of motor rotor

A technology of a motor rotor and a winding method, which is applied in the field of motor rotor winding, can solve the problems of poor motor electromagnetic compatibility, slow motor starting speed, and small motor stall torque, so as to improve electromagnetic compatibility and improve stall torque. , the effect of small starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

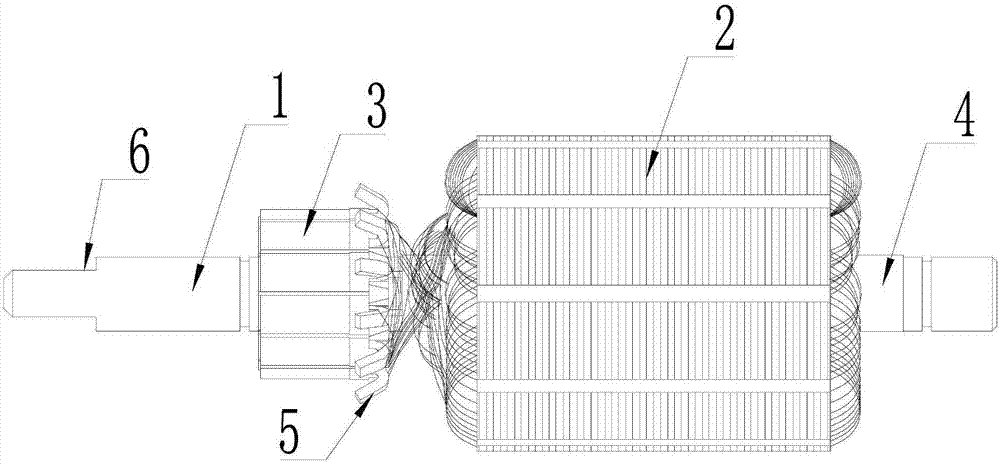

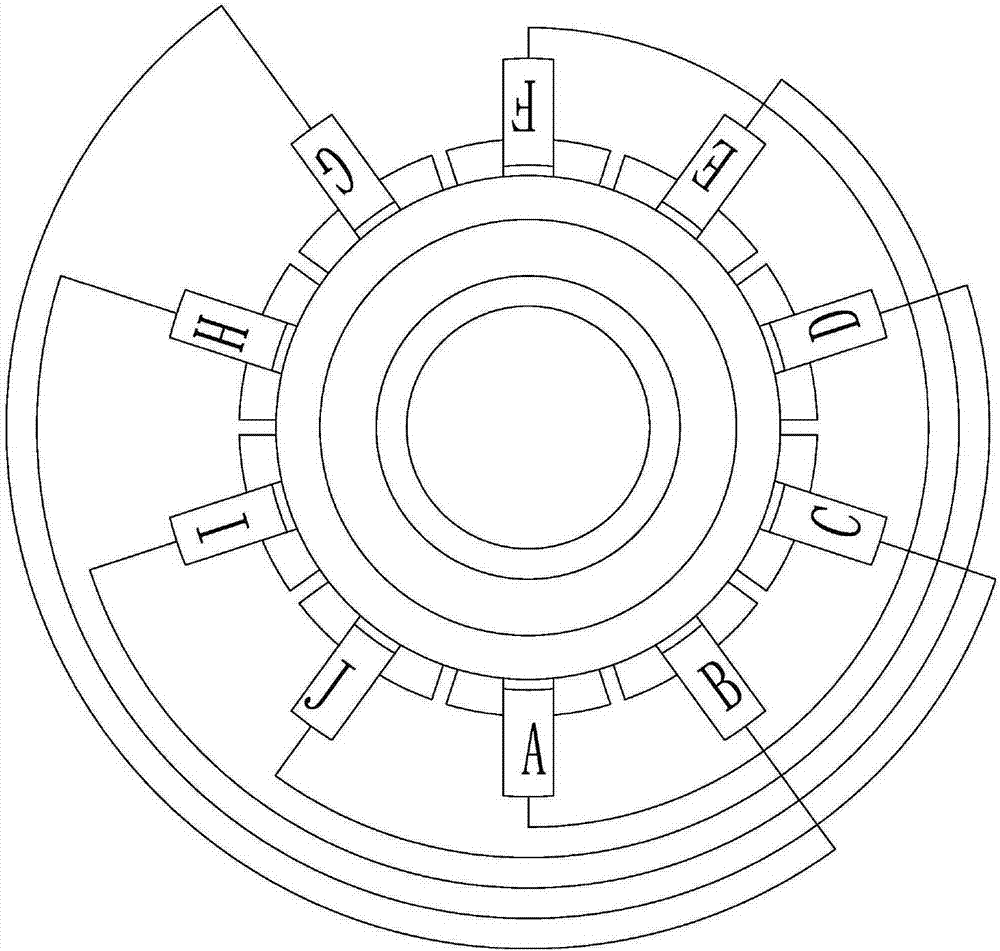

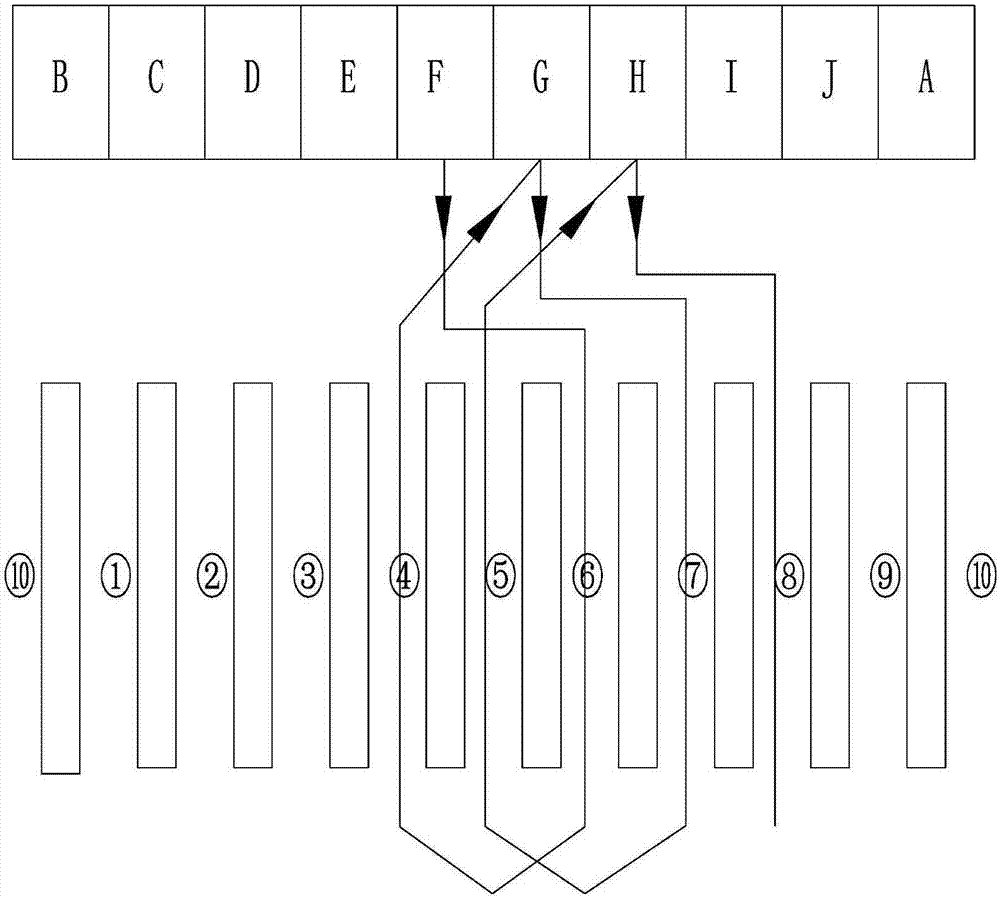

[0017] refer to Figure 1 ~ Figure 3 Shown: a winding method of a motor rotor, the motor rotor includes a rotating shaft 1, the middle of the rotating shaft 1 is provided with an insulating groove 4 in the circumferential direction, and 10 silicon steel sheets 2 arranged at intervals are evenly distributed in the circumferential direction of the insulating groove 4; the insulating groove The setting of 4 plays the role of protective insulation, avoiding the direct connection of the winding wire with the shaft 1, causing a short circuit; the silicon steel sheet 2 can reduce the heat generation and the electromagnetic interference to the surrounding environment, and through the setting of the silicon steel sheet 2, the There are 10 winding grooves formed between silicon steel sheets 2, and the winding grooves are silicon steel sheet groove ①, silicon steel sheet groove ②, silicon steel sheet groove ③, silicon steel sheet groove ④, silicon steel sheet groove ⑤, silicon steel sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com