Three-axis positioning device and method based on machine vision

A machine vision, axis positioning technology, applied in PCB positioning, electrical components, printed circuit manufacturing and other directions in the processing process, can solve the problems of small line spacing, high density of electronic circuits, PCB and exposure film deformation, etc., to improve accuracy and speed, the effect of solving the positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

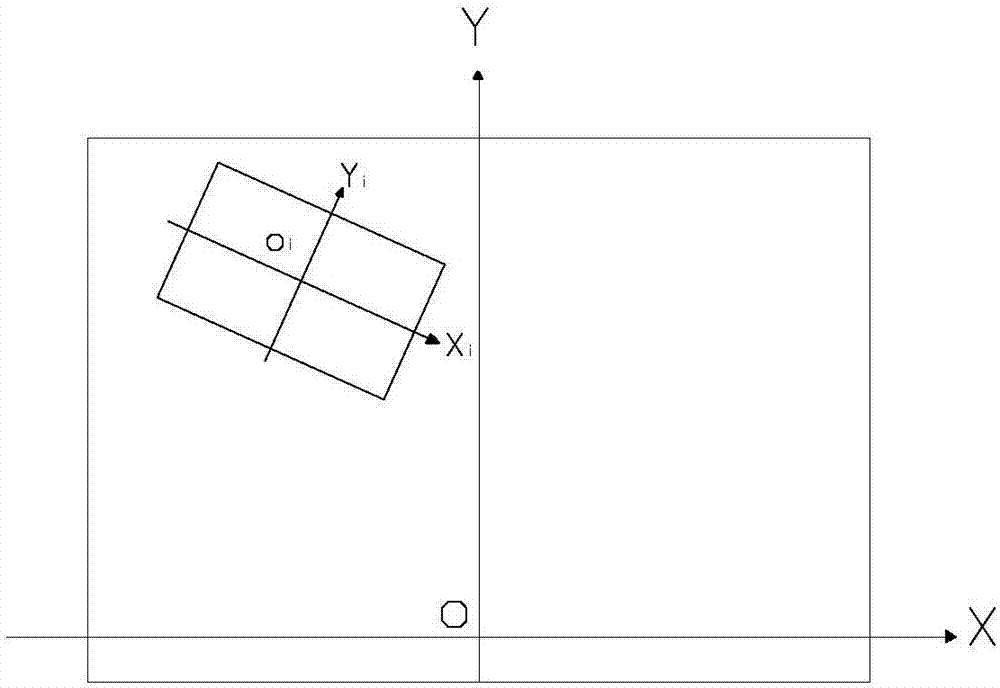

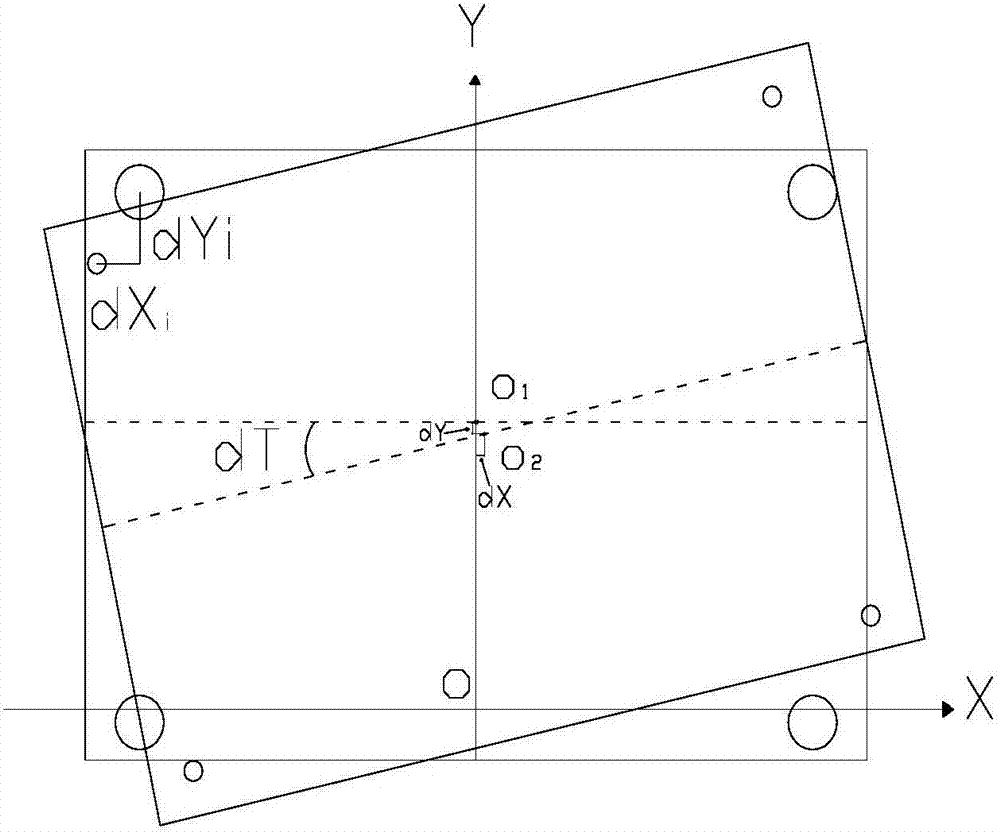

[0025] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

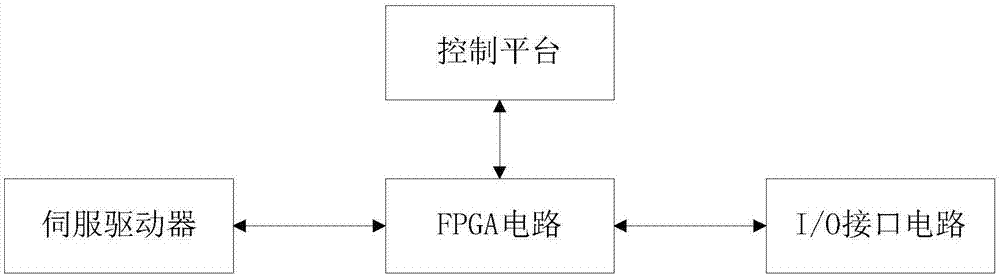

[0026] Such as figure 1 As shown, the present invention provides a kind of three-axis positioning device based on machine vision, comprises control platform, CCD image sensor, FPGA circuit, servo driver and I / O interface circuit, and CCD image sensor and FPGA circuit are all connected with control platform, servo The driver and the I / O interface circuit are all connected to the FPGA circuit; the CCD image sensor is used to obtain the position image signal and send it to the control platform, so that the control platform sends the control signal to the FPGA circuit according to the position image signal, and the FPGA circuit is used for Drive the external drive motor to work through the I / O interface circuit according to the control signal.

[0027] The FPGA circuit receives the control signal of the control platform, and according to the control signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com