Electric die-casting machine

A die-casting machine and electric technology, applied in the direction of mechanical equipment, shock absorbers, springs/shock absorbers, etc., can solve the problems of shortened life of one-way clutches and screw shafts, increased vibration and noise, and smooth transfer, etc. problem, achieve the effect of preventing damage, suppressing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

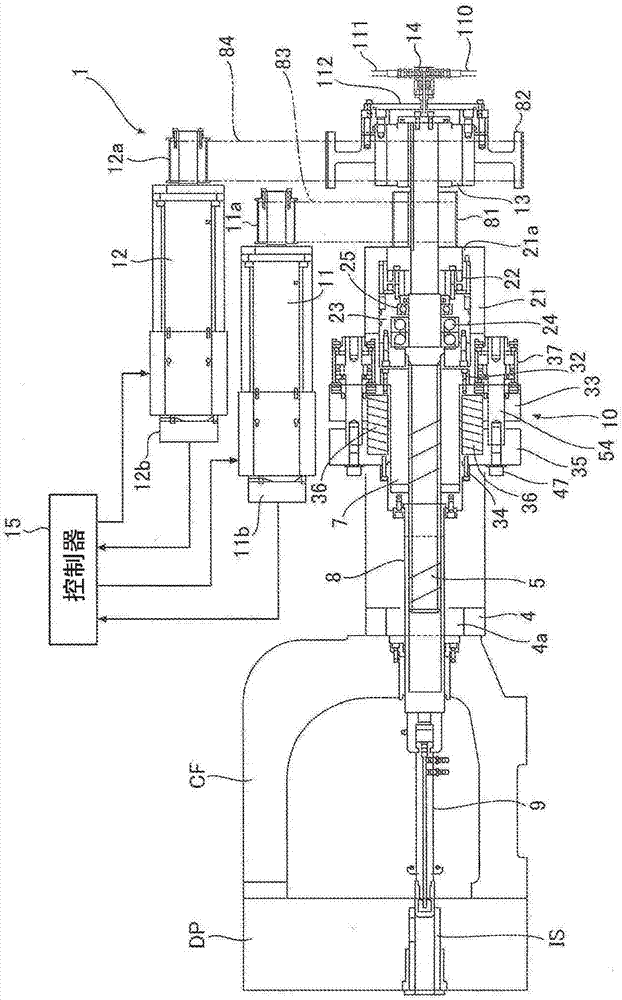

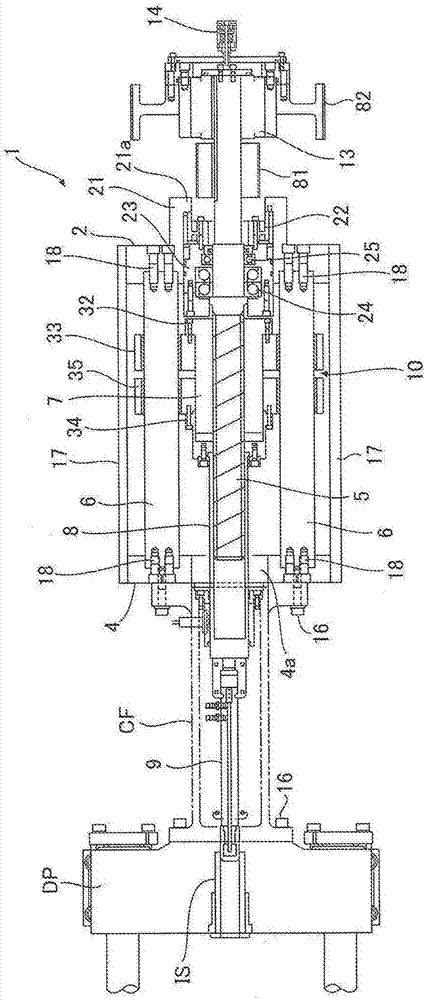

[0033] Embodiments of the electric die-casting machine of the present invention will be described below using the drawings.

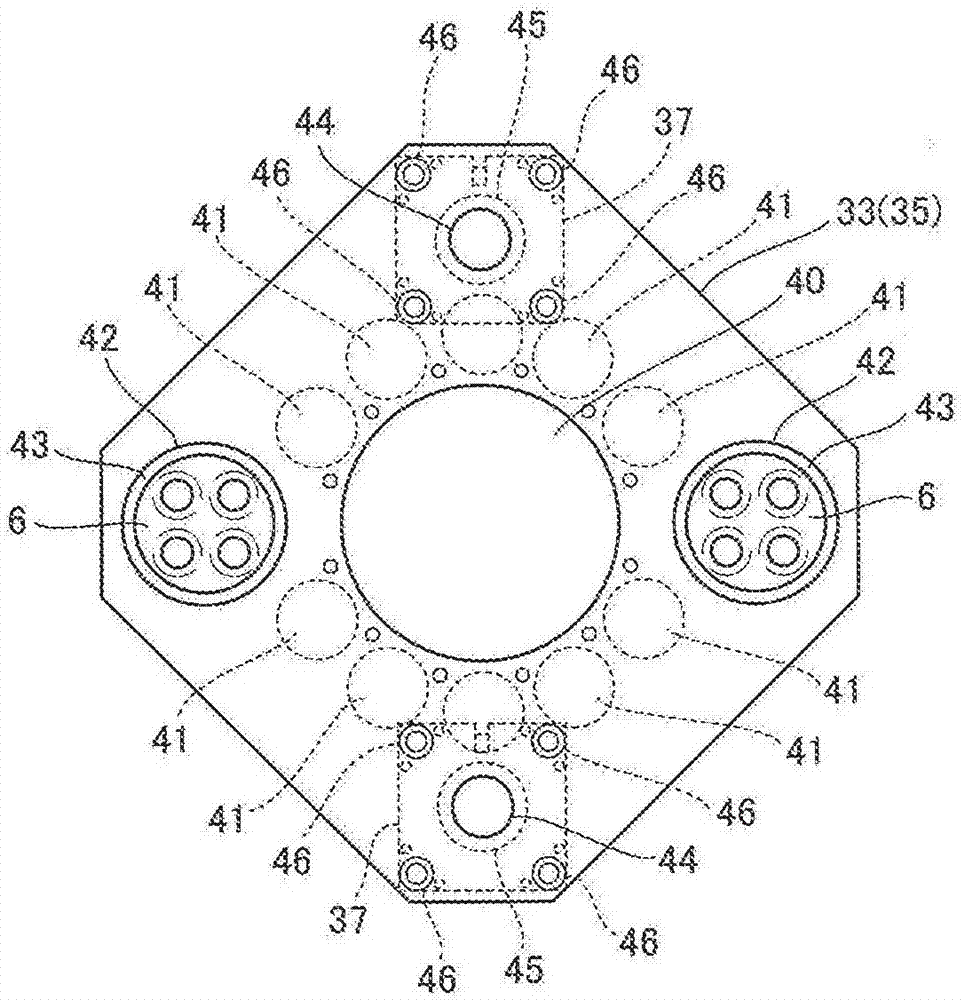

[0034] The electric die-casting machine of the embodiment has figure 1 and figure 2The electric injection molding unit 1 shown. As can be seen from the above drawings, the electric injection molding device 1 of this embodiment has: a first holding plate 2 and a second holding plate 4, the first holding plate 2 and the second holding plate 4 are arranged facing each other with a predetermined interval; Shaft 5, the screw shaft 5 is held rotatably by the first holding plate 2; guide rod 6, the two ends of the guiding rod 6 are fixed to the first holding plate 2 and the second holding plate 4; nut piece 7, the nut piece 7 is screwed with the screw shaft 5, and the nut piece 7 is driven to advance and retreat along the guide rod 6 by driving the screw shaft 5 to rotate; a cylindrical connecting piece 8, one end of which is fixed to the front end of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com