Method for manfacturing ceramic-based composite material

A manufacturing method and technology of composite materials, applied in the direction of ceramic layered products, chemical instruments and methods, lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, some embodiments will be described with reference to the drawings.

[0023] A suitable application of the ceramic matrix composite material according to one embodiment is a mechanical part exposed to a high-temperature environment such as a component part of a jet engine for an aircraft, and examples thereof include turbine blades, combustion chambers, afterburners, and the like. Of course, it can also be applied to other purposes.

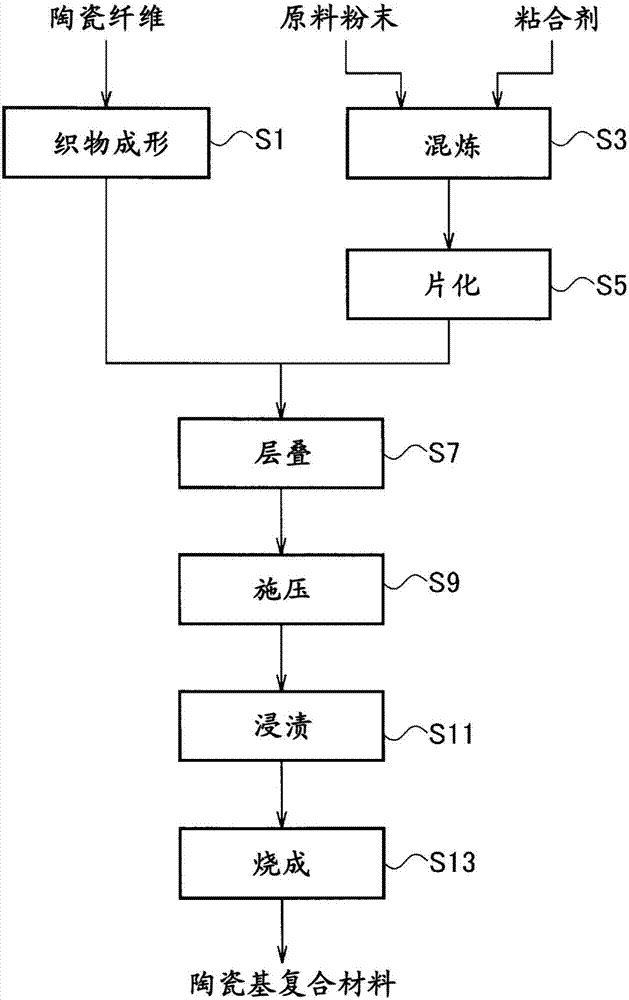

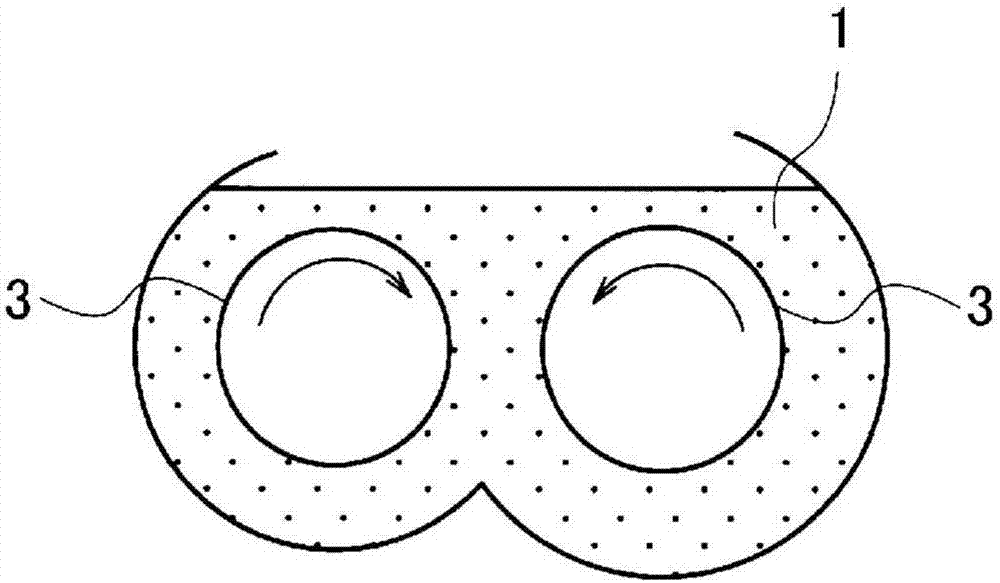

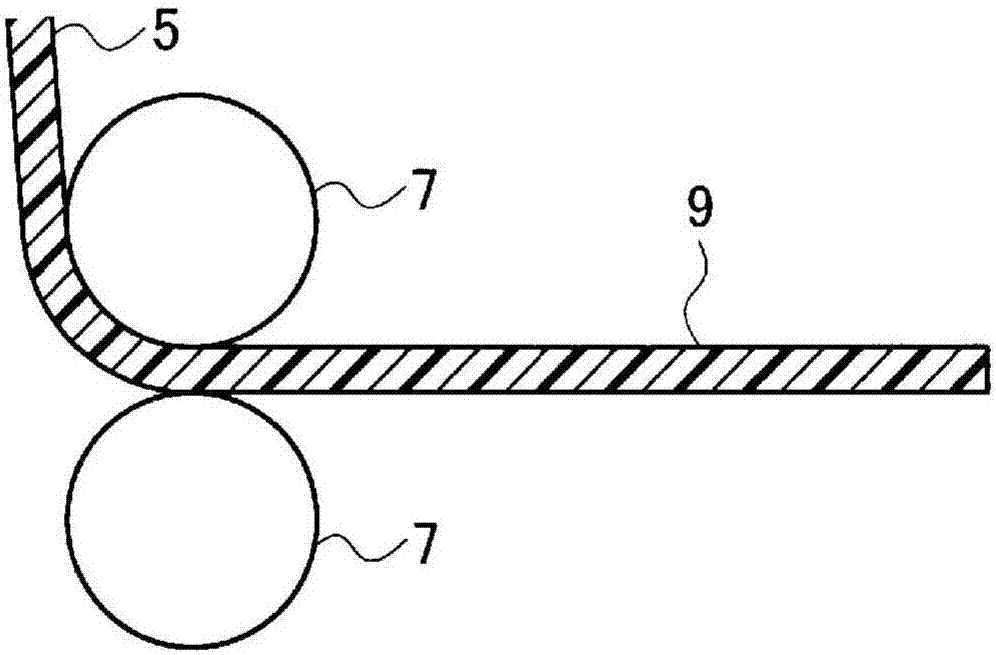

[0024] A ceramic matrix composite material according to one embodiment generally includes a fabric made of inorganic fibers such as silicon carbide (SiC), and a matrix that binds the fabric made of inorganic substances such as SiC. The manufacturing method of this ceramic matrix composite generally includes: making aggregate powder as a matrix raw material in a binder such as a thermoplastic resin to form a sheet, laminating the sheets and fabrics alternately, and applying pressure to make the aggregate soaks into the fabric. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com