Multi-section atomization regent feeding equipment

A multi-stage, dosing technology, applied in the direction of solid separation, flotation, etc., can solve the problems that the flotation column does not have a stirring effect and affects the foam particles, etc., to shorten the mixing time, improve the flotation index, and reduce the dosage of chemicals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

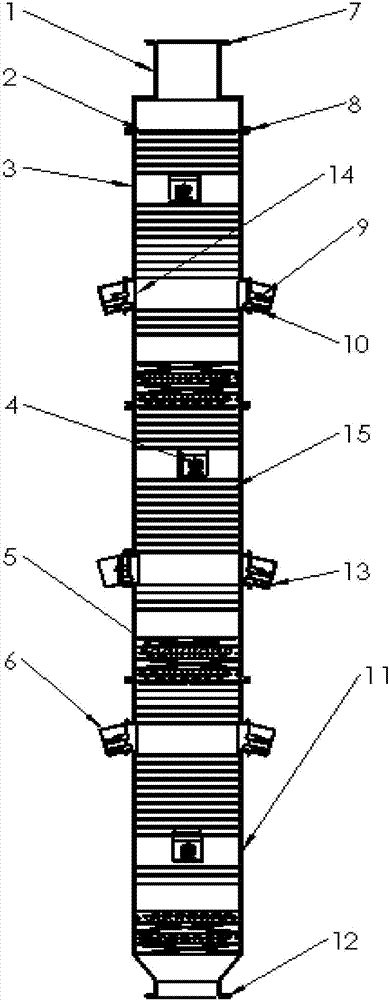

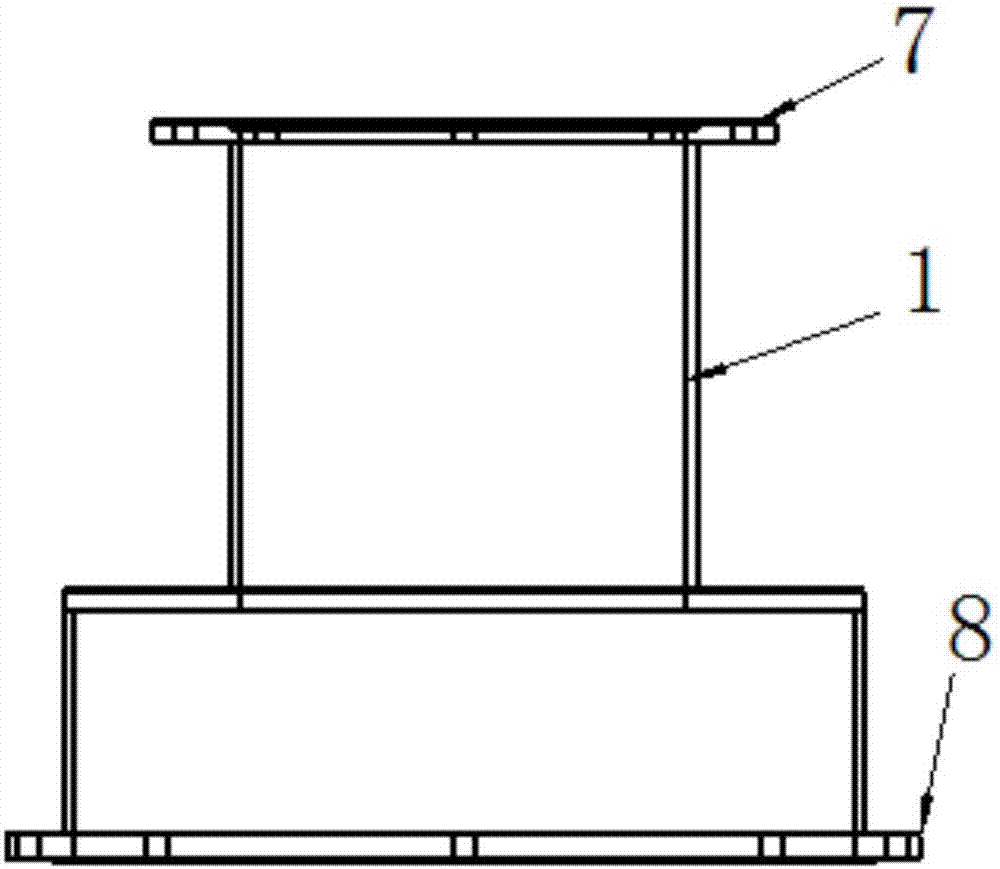

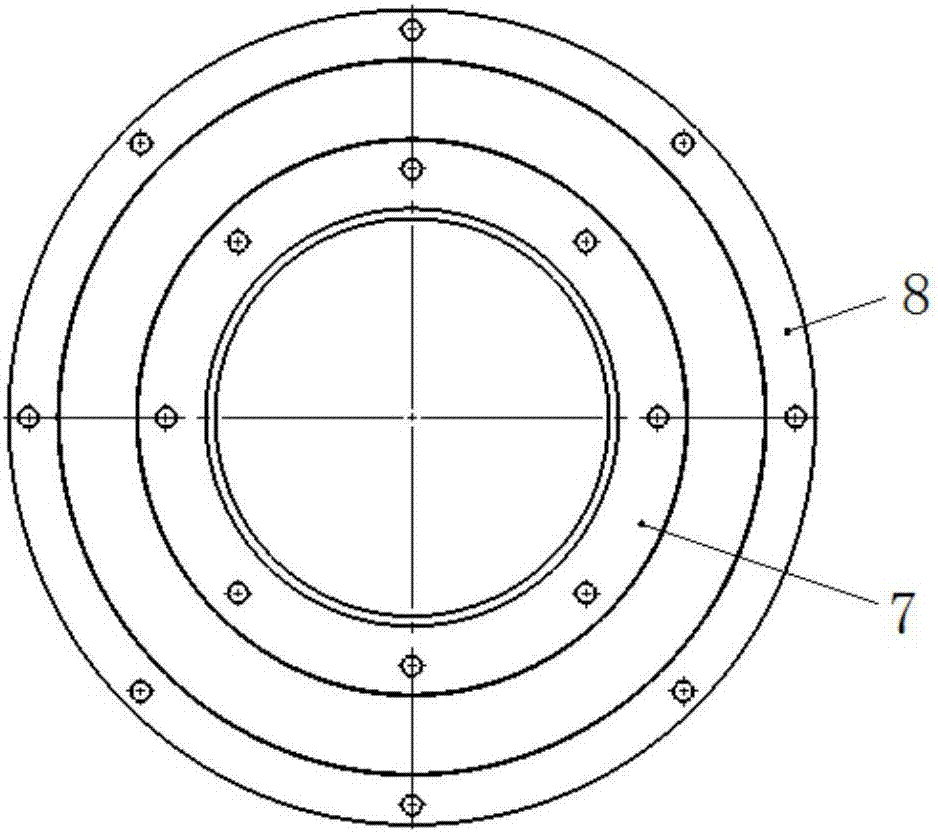

[0041] refer to Figure 1 to Figure 20 As shown, the multi-stage atomization drug delivery equipment in an embodiment provided by the present invention includes a mine supply part, a cylinder part and a mine discharge part, the mine supply part is connected with the upper end of the cylinder part through a flange, and the cylinder The lower end of the part is connected with the ore discharge part through the flange, and there are several slurry mixing parts distributed on the inner wall of the cylinder part from top to bottom;

[0042] Wherein, each slurry mixing part includes an atomizing nozzle device and an ore-separating sieve plate, the ore-separating sieve plate is arranged horizontally in the cylinder part, the atomizing nozzle device is arranged above the ore-separating sieve plate, and the atomizing nozzle is arranged on the cylinder body On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com