A segmented horizontal well thermal co 2 Huff and puff mining method of heterogeneous gas hydrate reservoir

A hydrate and heterogeneous technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems that affect the development effect, the degree of effect difference, and the lack of research on hydrate reservoirs, etc., and achieve improvement Mining effect, convenient operation and strong economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited.

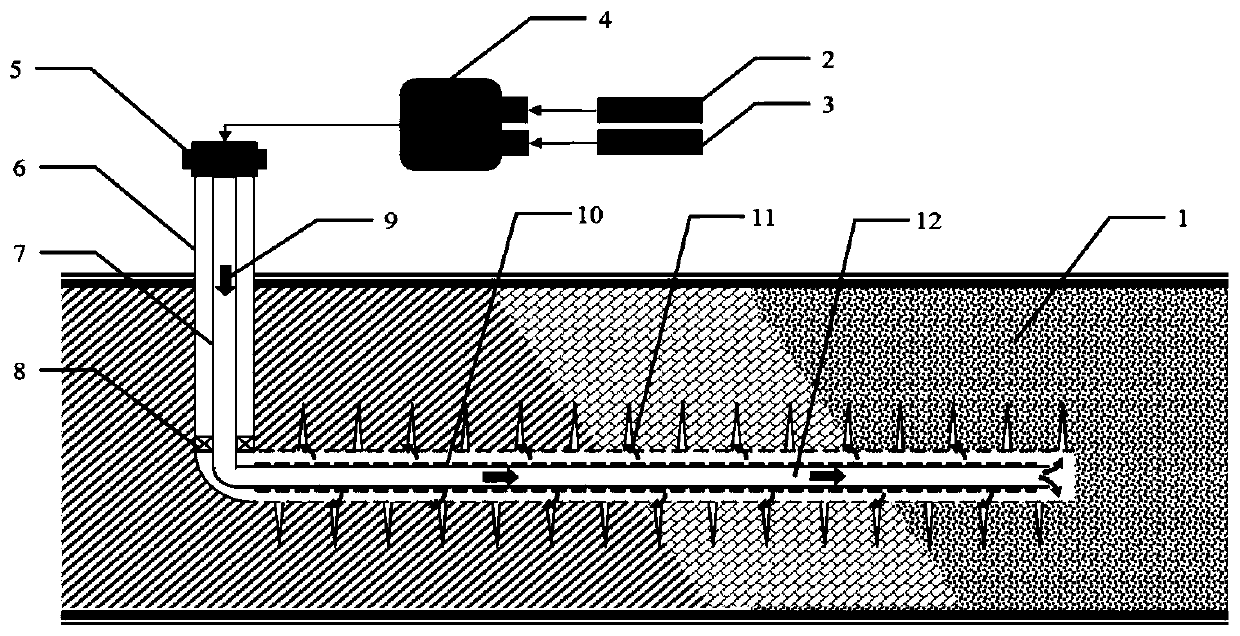

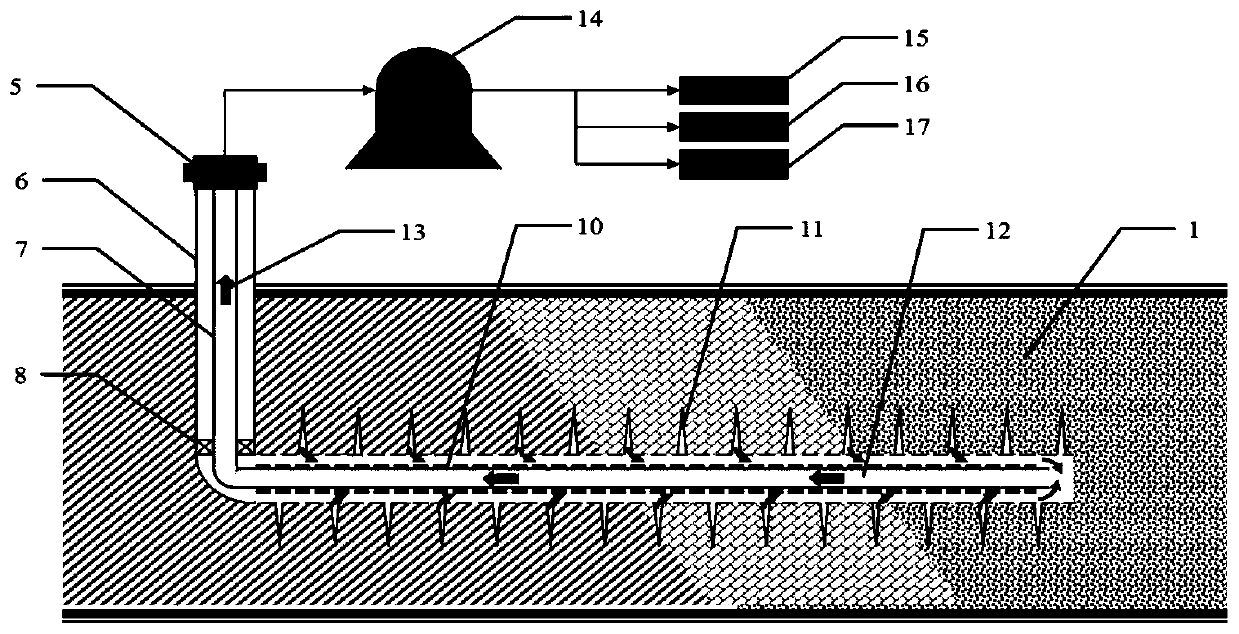

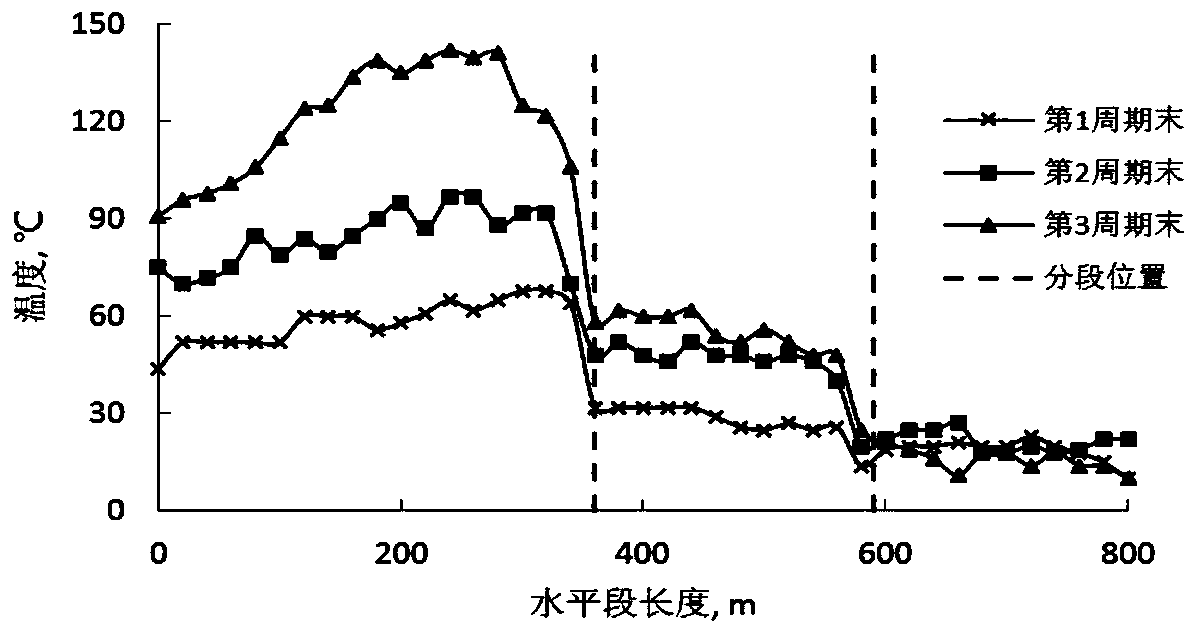

[0028] According to regional geological data, hydrate reservoirs with strong heterogeneity are selected for construction operations, such as figure 1 As shown, the coefficient of variation of permeability of heterogeneous hydrate reservoir 1 is 0.7;

[0029] Such as figure 1 shown, at a distance of 1 distance from the top of the hydrate reservoir Drill a horizontal production well at the position, and the length of the horizontal well section 12 of the horizontal production well is 800m. The horizontal well section 12 is perforated 11, and the vertical well section 7 and the horizontal well section 12 of the horizontal production well are 2~ A packer 8 is installed in the oil casing annulus at 5m, the tubing in the vertical well section 7 is made of polyethylene material to reduce heat loss, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com