Sewage and boiler flue gas treatment device and method for zero-emission auxiliary steam thermal recovery

A technology for auxiliary steam and boiler flue gas. It is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc. It can solve problems such as environmental pollution and waste of water resources, and achieve improved oil recovery , protect the environment, improve the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

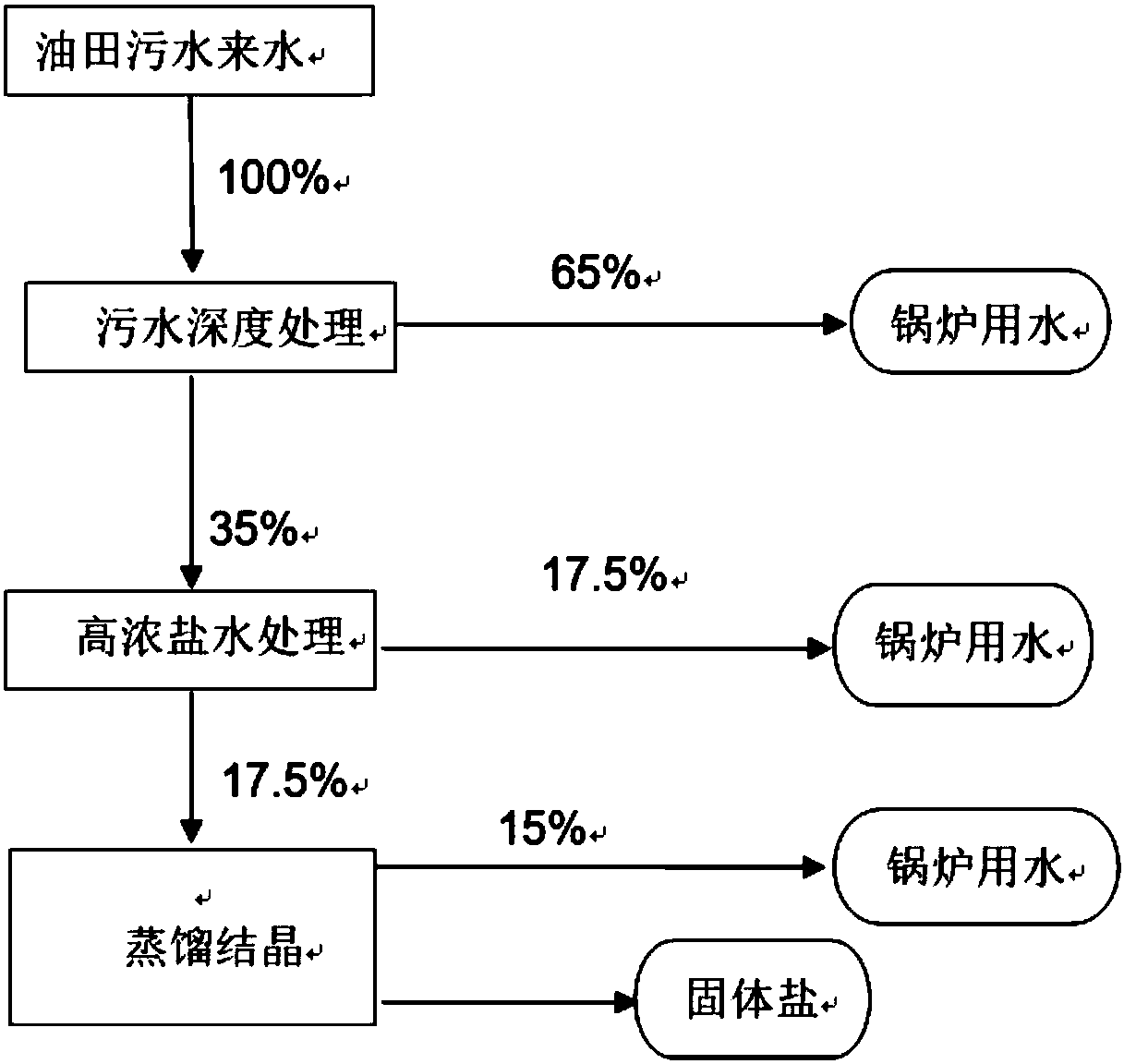

[0036] Sewage and flue gas treatment zero discharge assisted steam thermal recovery method

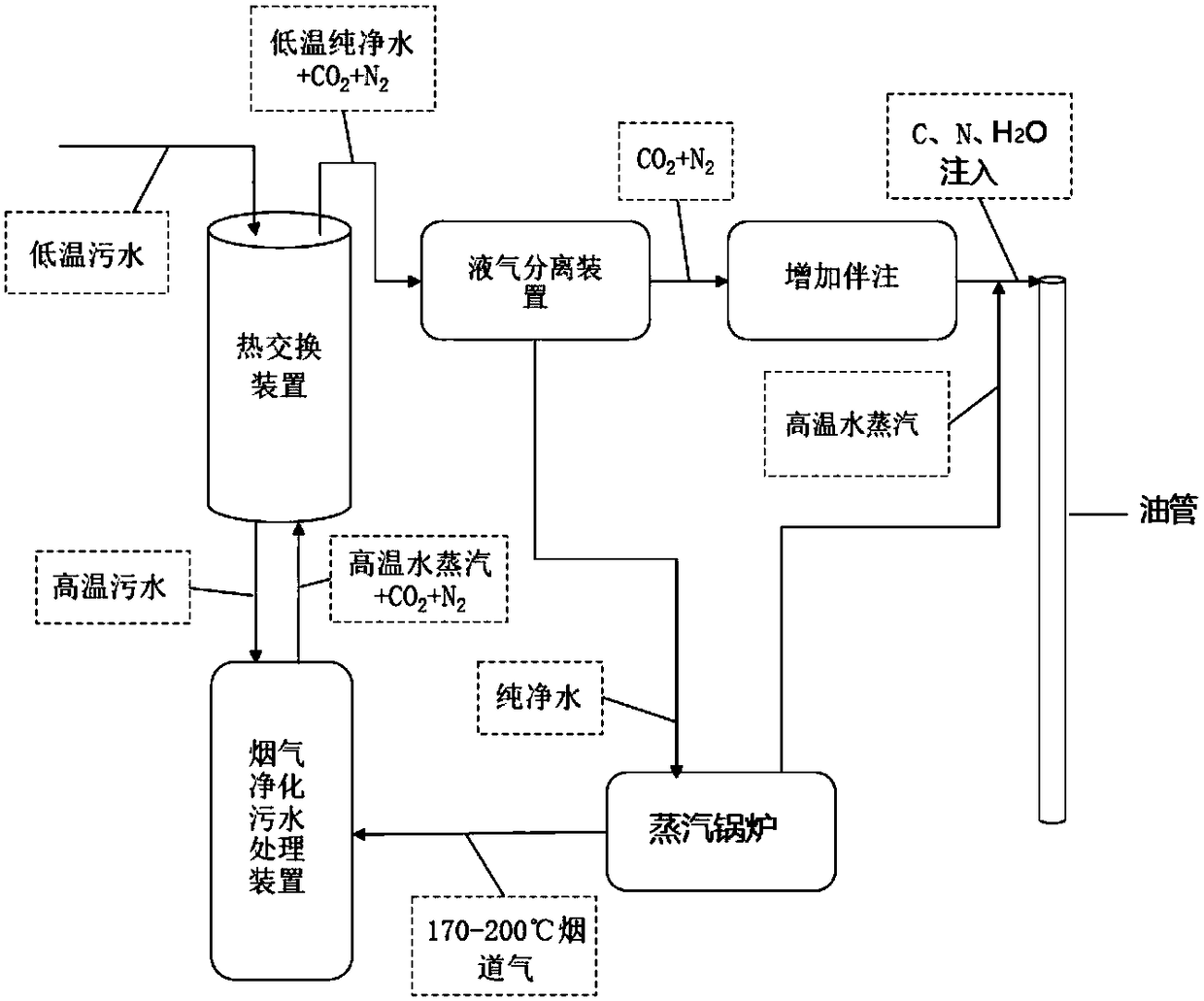

[0037] Such as figure 2 As shown, the low-temperature (5-25°C) sewage generated by oil field production passes through the heat exchange device and the flue gas entering the heat exchange device is converted into high-temperature sewage (30-35°C); the high-temperature sewage enters the flue gas purification and sewage treatment device , high-temperature sewage is sprayed down from the upper part of the flue gas purification and sewage treatment device (the water pressure of the spray is controlled within 0.2Mpa, and the flow rate is not limited), and it contacts with the flue gas entering the flue gas purification and sewage treatment, and the waste flue gas The sulfur dioxide in the waste water is dissolved in the sewage, and the sewage continues to be further treated through the sewage treatment plant to usable fresh water (the waste water is then sent to the waste water treatment p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com